Solidification: Phase Formation

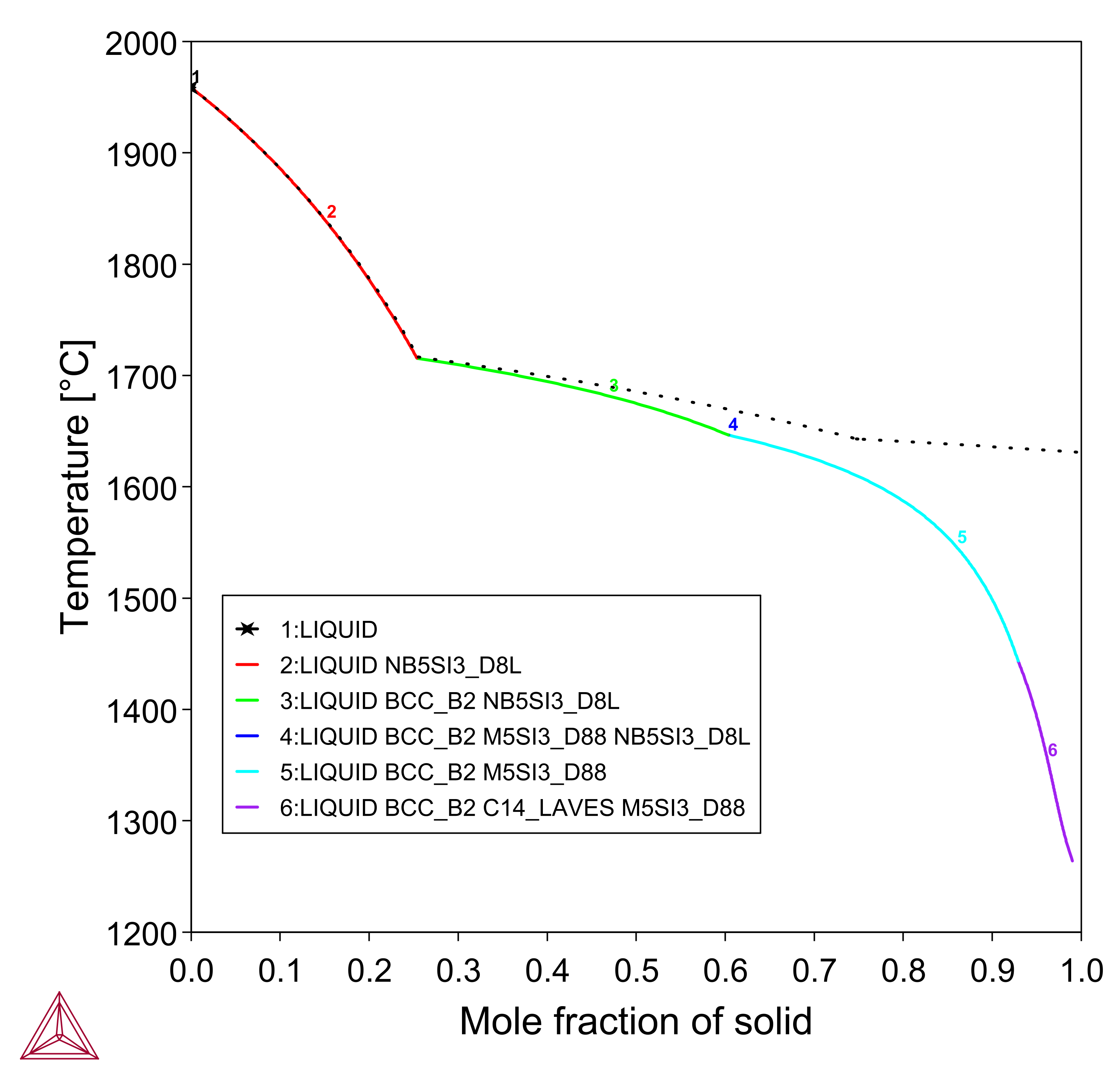

You can also use the TCS Nb-based Alloys Database (TCNB) to study solidification and phase formation. A conventional Scheil simulation provides an upper boundary for how far a solidification can deviate from equilibrium, therefore a real solidification is expected to occur between the equilibrium simulation and the Scheil simulation. In Thermo-Calc performing a Scheil simulation always triggers an equilibrium simulation.

Read more about Scheil Solidification Simulations on our website, including how to select the right model for your simulation. If you are in Thermo‑Calc, press F1 to search the help to learn about using Scheil.

The results in the table and figure below show that the phase types from Scheil simulations for the as-cast Nb-Si alloys are in consistent experimental observed ones.

| Comparison between the phases observed from as-cast Nb-Hf-Si-Ti alloys [2007Yan] and those predicted from Scheil simulation | ||

|---|---|---|

| Alloy Composition | Phases observed from as-cast alloys | Phases predicted from Scheil simulation |

| Nb-7.5Hf-21Ti-16Si | Bcc, M3Si | Bcc, M3Si |

| Nb-12.5Hf-21Ti-16Si | Bcc, M3Si | Bcc, M3Si |

| Nb-10Hf-33Ti-16Si | Bcc, M3Si, M5Si3 | Bcc, M3Si, M5Si3 |

| Nb-8Hf-25Ti-22Si | Bcc, M3Si, Nb5Si3 | Bcc, M3Si, Nb5Si3 |

Figure 1: Calculated solidification path of Nb-5Al-5Cr-5Hf-2Mo-18Si-24Ti [2007Gen] using the Scheil and equilibrium model.

References

[2007Gen] J. Geng, P. Tsakiropoulos, A study of the microstructures and oxidation of Nb–Si–Cr–Al–Mo in situ composites alloyed with Ti, Hf and Sn. Intermetallics. 15, 382–395 (2007).

[2007Yan] Y. Yang, B. P. Bewlay, Y. A. Chang, Liquid-Solid Phase Equilibria in Metal-Rich Nb-Ti-Hf-Si Alloys. J. Phase Equilibria Diffus. 28, 107–114 (2007).