About the Precipitation Module (TC-PRISMA)

The Precipitation Module, or TC‑PRISMA, is an Add-on Module to Thermo‑Calc and it is available in Graphical Mode as the Precipitation Calculator.

The Module treats concurrent nucleation, growth/dissolution and coarsening under arbitrary heat treatment conditions in multi-component and multi-phase systems using Langer-Schwartz theory and the Kampmann-Wagner numerical approach. It is a general computational tool for simulating kinetics of diffusion controlled multi-particle precipitation processes in multicomponent and multiphase alloy systems.

You can use the Precipitation Module for:

- Concurrent nucleation, growth/dissolution and coarsening of precipitates

- Normal grain growth and Zener pinning

- Temporal evolution of particle size distribution

- Average particle radius and number density

- Volume fraction and composition of precipitate

- Nucleation rate and coarsening rate

- Time-Temperature-Precipitation (TTP) diagrams

- Continuous-Cooling-Transformation (CCT) diagrams

- Estimation of multi-component interfacial energy

- Estimation of yield stress using the Yield Strength Property Model

The configuration of the Yield Strength Property Model is completed on the Property Model Calculator and then accessed as a variable with the Plot Renderer or Table Renderer.

In order to perform a simulation in the Precipitation Module, both a thermodynamic database and a kinetic database is needed. The thermodynamic database is a normal Thermo‑Calc database, whereas the kinetic database contains information about the atomic mobility of individual elements in various phases.

Precipitation, formation of particles of a second phase, or second phases from a supersaturated solid solution matrix phase, is a solid state phase transformation process that has been exploited to improve the strength and toughness of various structural alloys for many years. This process is thermochemically driven and fully governed by system (bulk and interface) thermodynamics and kinetics.

Typically, a precipitation process has three distinctive stages: nucleation, growth, and coarsening. However, under certain conditions, these can also happen at the same time. With the Precipitation Module, the kinetics of concurrent nucleation, growth, and coarsening can be simulated by calculating the evolution of the probability distribution of the particle number densities, usually called particle size distribution (PSD). The simulation results can be used to understand and guide how to obtain desirable precipitates with certain PSD or to avoid undesirable precipitations during heat treatments of alloys such as aging and tempering.

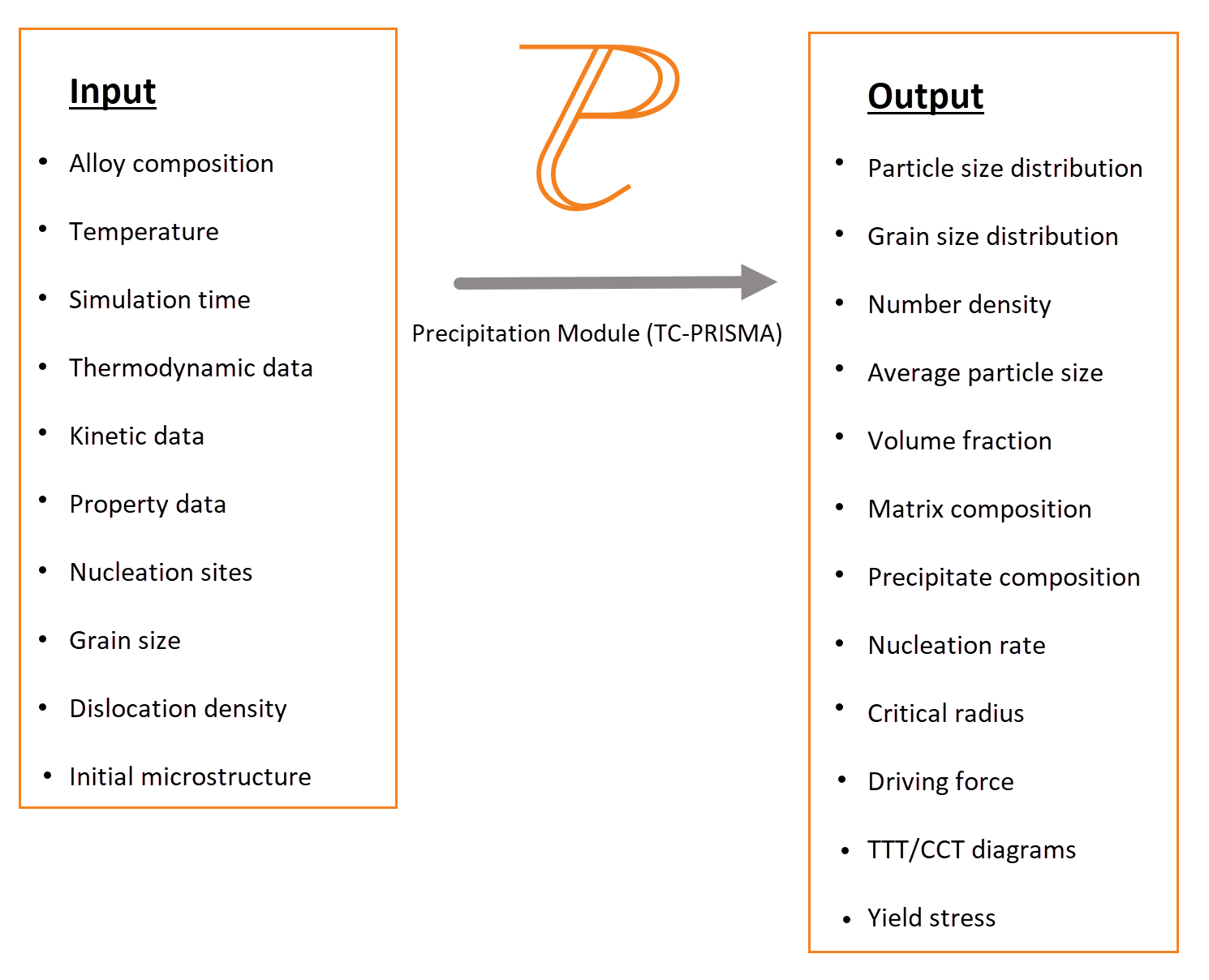

A summary for the input and output of the Precipitation Module is shown.

Input and Output of the Precipitation Module

The Precipitation Module relies on CALPHAD-based software tools and databases to provide the necessary bulk thermodynamic and kinetic data for phases in multicomponent systems. The CALPHAD approach has been developed for more than 50 years and is routinely applied to design new alloys and optimize existing materials within various metal industries, such as steels and alloys of nickel, titanium, aluminum and magnesium.

The power of this approach is due to the adopted methodology where free energy and atomic mobility of each phase in a multicomponent system can be modeled hierarchically from lower order systems, and model parameters are evaluated in a consistent way by considering both experimental data and ab-initio calculation results. The Precipitation Module is directly integrated into Thermo‑Calc, a CALPHAD-based computer program for calculating phase equilibrium. Another Add-on Module, the Diffusion Module (DICTRA) is available for diffusion controlled phase transformation in multicomponent systems.

With Thermo‑Calc and the accompanying thermodynamic and mobility databases, almost all fundamental phase equilibrium and phase transformation information can be calculated without unnecessary and inaccurate approximations. For example you can calculate:

- Driving forces for nucleation and growth

- Operating tie-lines under local equilibrium conditions

- Deviations from local equilibrium at interfaces due to interface friction

- Atomic mobilities or diffusivities in the matrix phase

In addition to bulk thermodynamic and kinetic data, a few other physical properties, such as interfacial energy and volume, are needed in precipitation models. These additional physical parameters can be obtained by experiments or other estimation models or first principles calculations. Volume data are available in most of our thermodynamic databases . The Precipitation Module has an estimation model available for interfacial energy.

This guide is a supplement to the full Thermo‑Calc documentation set. It is recommended that you use the Online Help, which you can access in Thermo-Calc by pressing F1 or from the main menu choose Help → Online help.