Applications Using the Diffusion Module (DICTRA)

These examples use the thermodynamic TCS Mo-based Alloys Database (TCMO)and its compatible TCS Mo-based Alloys Mobility Database (MOBMO) with the Add-on Diffusion Module (DICTRA).

Read more about the Diffusion Module (DICTRA) on our website. There is also a Getting Started with the Diffusion Module (DICTRA) page available. If you are in Thermo‑Calc, press F1 to search the help to learn about the available settings included with the Add-on Module.

Intermetallic Formation on Diffusion Behavior for Zr-Mo Alloys

This example examines the impact of Mo2Zr intermetallic formation on diffusion behavior in Zr-Mo alloys used for nuclear applications

Zr-Mo alloys are widely used as nuclear fuel cladding materials and reactive structural materials due to their high density, radiation resistance, high strength, and favorable oxidation behavior with oxygen. The formation of intermetallic compound Mo2Zr enhances the alloy’s strength and radiation resistance. However, the diffusion processes within Mo2Zr and its solid solutions can interact, impacting the overall material properties. Therefore, studying and analyzing the diffusion behavior in the Zr-Mo binary system is crucial to understanding and optimizing the performance of the alloy.

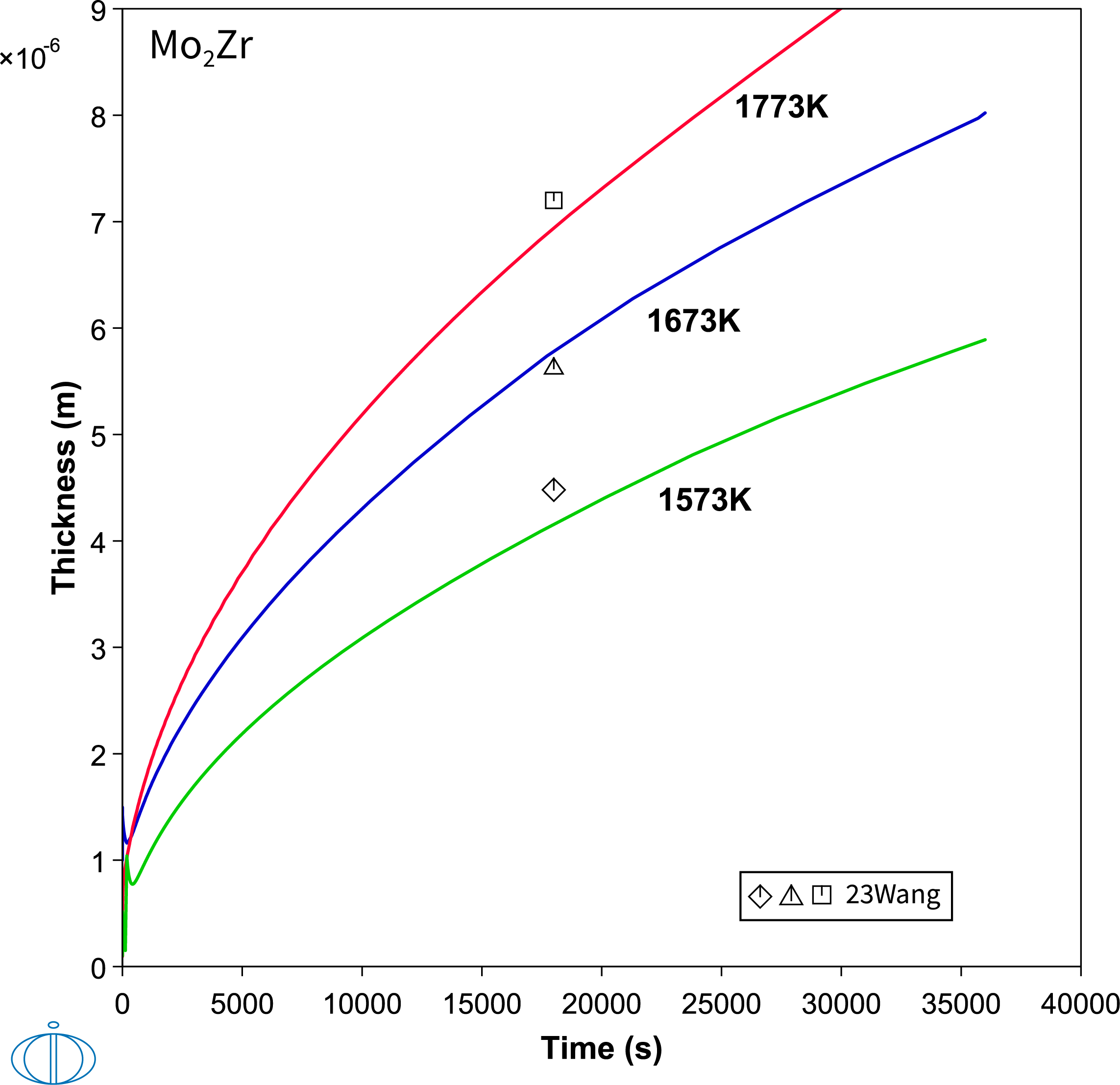

The following example shows the results from the Diffusion Module (DICTRA) simulation of growth of Mo2Zr compound layer in the Mo/Zr diffusion couple in the temperature range of 1573 K to 1773 K, using the latest versions of the databases (TCMO2 and MOBMO2).

Figure 1: The simulated growth of Mo2Zr layer in the Mo/Zr diffusion couple in the temperature range of 1573 K to 1773 K for 10 h, compared with the experimental data.

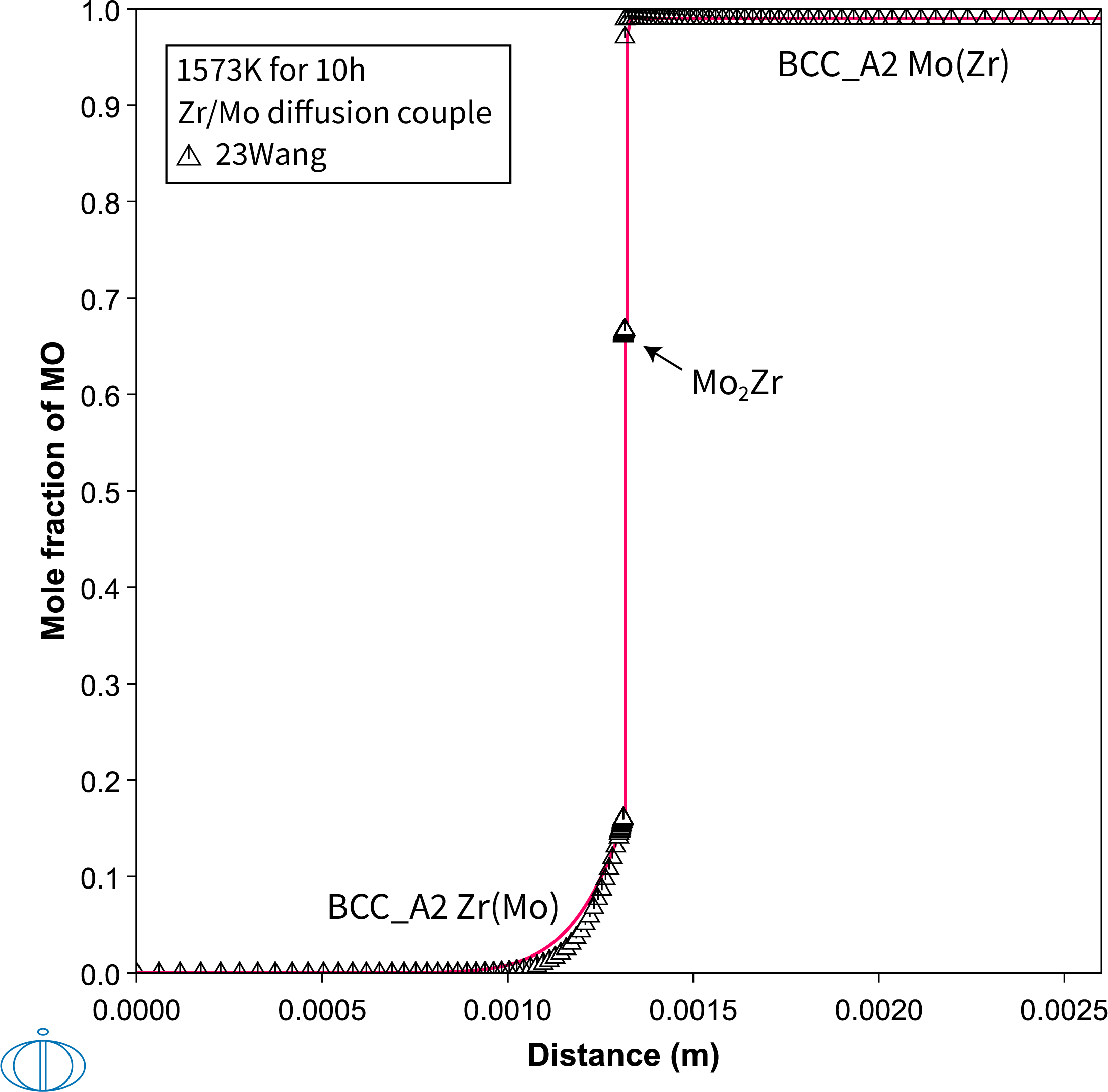

Figure 2: The simulated concentration profiles of Mo in the Zr/Mo2Zr/Mo diffusion couple at 1573 K for 10 h, using both the thermodynamic and kinetic Mo-based databases compared with the experimental data [2023Wan].

Diffusion Kinetics Simulation in BCC_A2 Mo Alloys

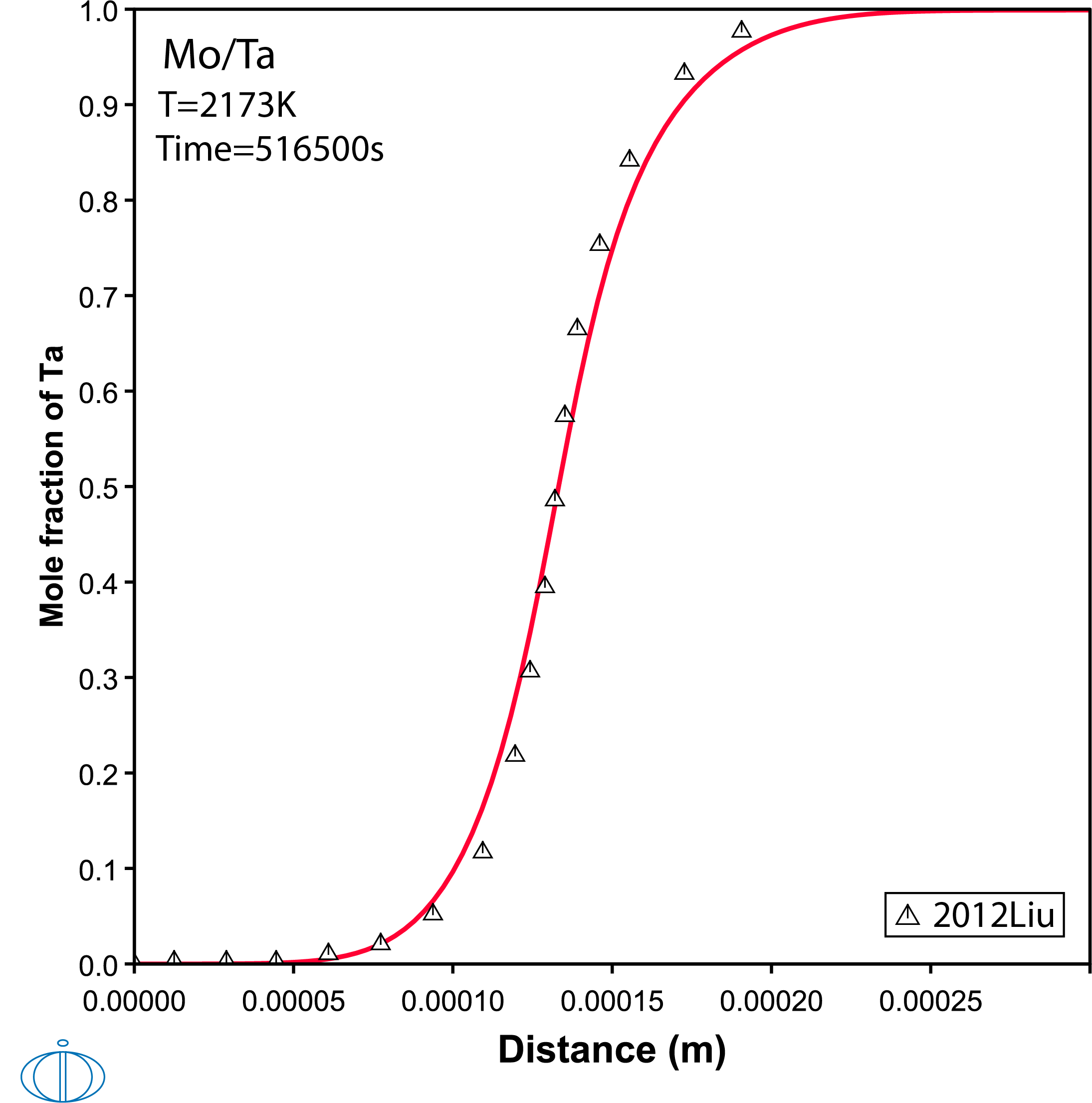

This example plots the simulation of a BCC_A2 Mo/Ta diffusion couple using the latest versions of the thermodynamic and mobility databases. The concentration profiles within the diffusion couple are simulated, with an annealing temperature 2173 K for 516500 s.

Figure 3: The simulated concentration profiles within the BCC_A2 Mo/Ta diffusion couple using the Diffusion Module (DICTRA), with an annealing temperature 2173 K for 516500 s, and compared with the experimental data [2012Liu].

References

[2012Liu] Y. Liu, Z. Long, Y. Du, G. Sheng, J. Wang, L. Zhang, Diffusion characteristics and atomic mobilities for bcc refractory Mo–Ta, Mo–W, and Mo–Nb alloys. Calphad 36, 110–117 (2012).

[2023Wan] K. Wang, X. Liu, T. Liu, C. He, J. Liu, Interdiffusion in Zr-Mo/W Intermetallics. Appl. Sci. 13, 6375 (2023).