Solidification Path of TiC-added Mo-Si-B Alloys

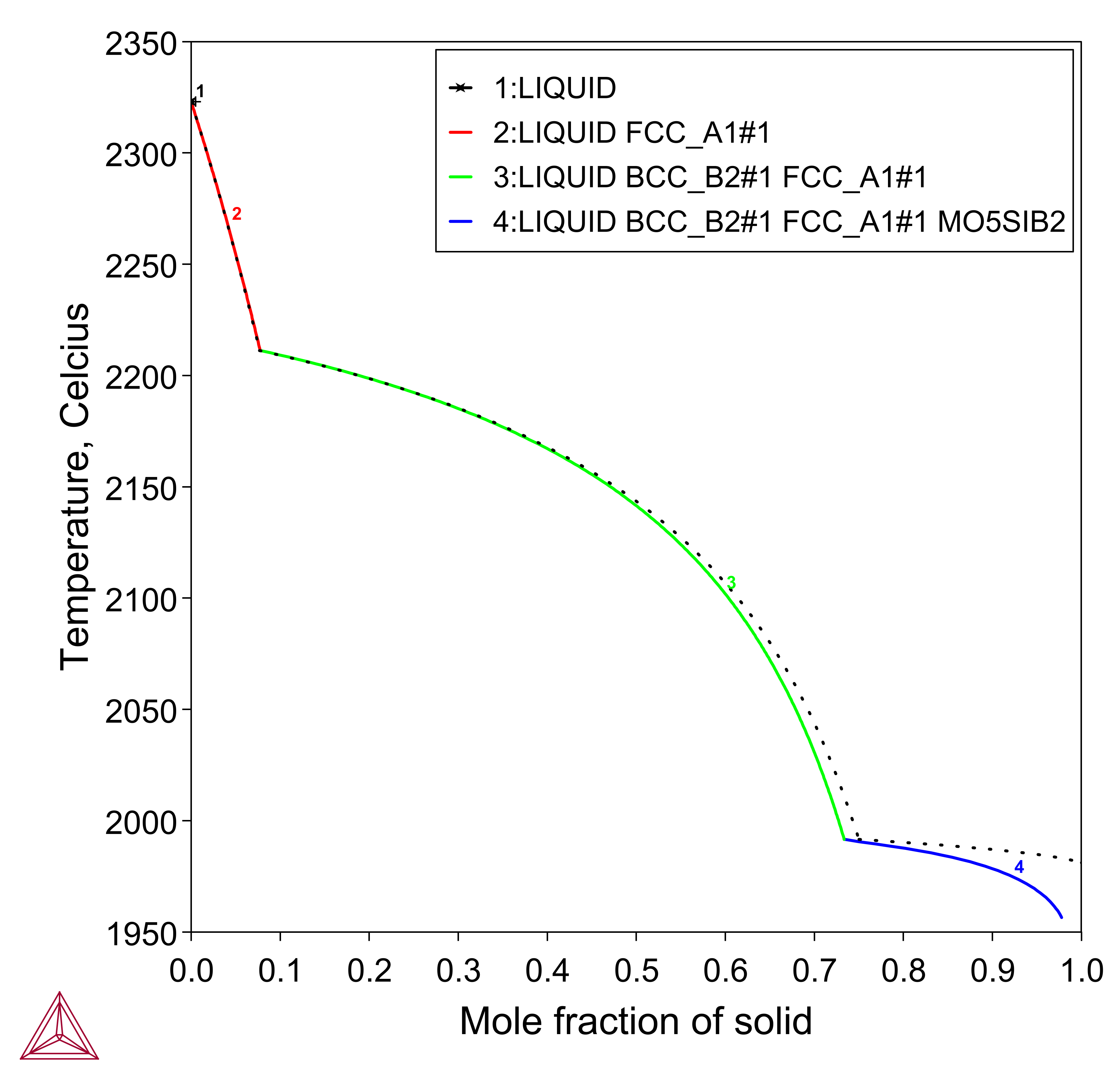

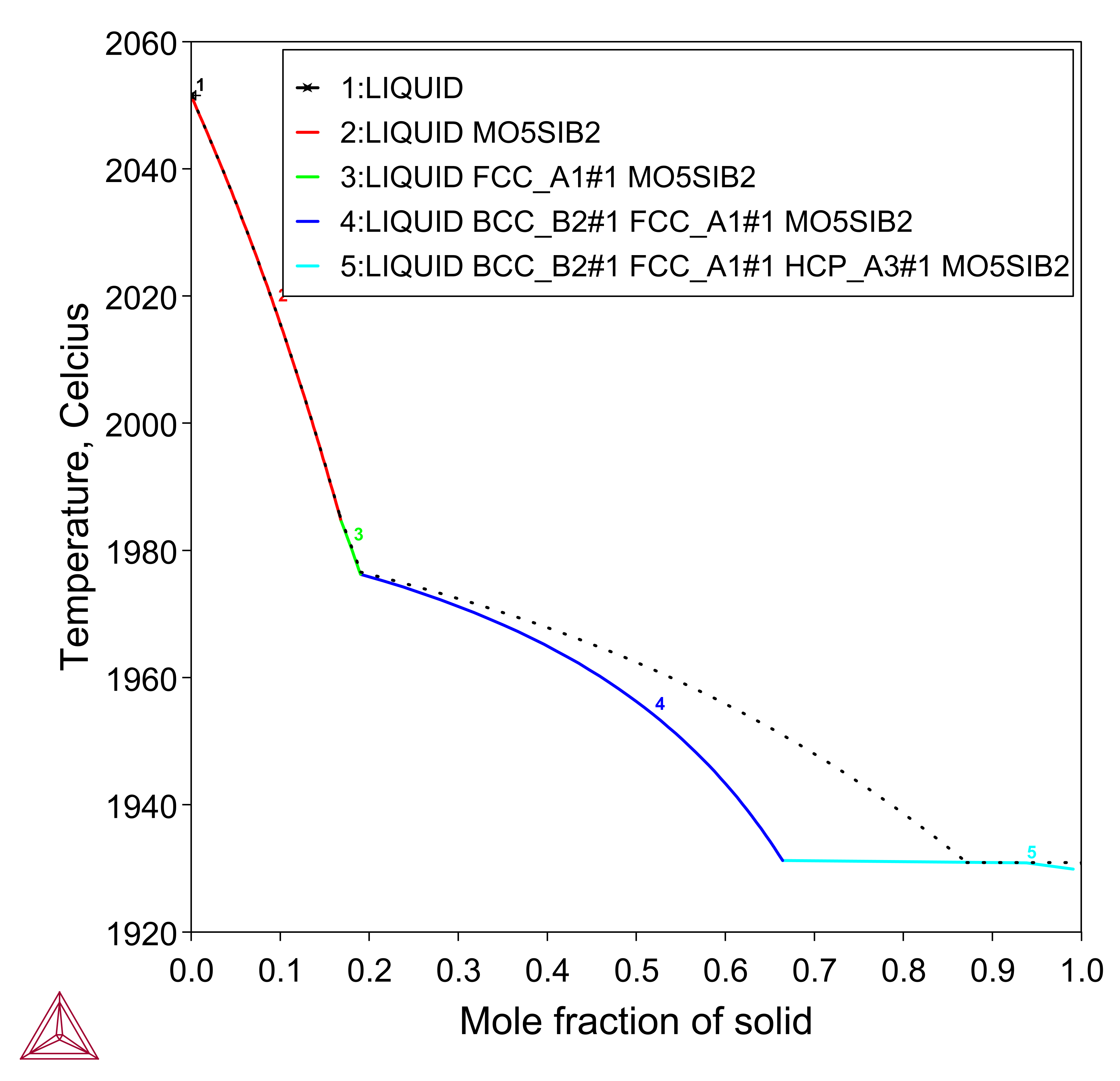

For TiC-added Mo-Si-B alloys, the primary phase is considerably influenced by the alloy composition. The TCS Mo-based Alloys Database (TCMO) can also predict the solidification path for these alloys. For example, in the Mo-1.7Si-3.3B-15TiC (at.%) alloy, TiC solidifies first, followed by the BCC+TiC eutectic. By contrast, in the Mo-6.7Si-13.3B-7.5TiC (at.%) alloy, the primary solidification phase becomes T2. The predicted solidification paths and primary solidification phases are consistent with the experimental observation from [2014Miy].

Read more about Scheil Solidification Simulations on our website, including how to select the right model for your simulation. If you are in Thermo‑Calc, press F1 to search the help to learn about using Scheil.

Figure 1: Equilibrium solidification and Scheil solidification simulations of the Mo-1.7Si-3.3B-15TiC (at.%) alloy. The predicted solidification path and primary solidification phase are consistent with the experimental observation from [2014Miy].

Figure 2: Equilibrium solidification and Scheil solidification simulations of the Mo-6.7Si-13.3B-7.5TiC (at.%) alloy. The predicted solidification path and primary solidification phase are consistent with the experimental observation from [2014Miy].

Reference

[2014Miy] S. Miyamoto, K. Yoshimi, S.-H. Ha, T. Kaneko, J. Nakamura, T. Sato, K. Maruyama, R. Tu, T. Goto, Phase Equilibria, Microstructure, and High-Temperature Strength of TiC-Added Mo-Si-B Alloys. Metall. Mater. Trans. A. 45, 1112–1123 (2014).