Diffusion Calculator Settings (Moving Phase Boundary)

After you have completed the settings for the System Definer you define the diffusion calculation parameters.

The phase interface between ferrite and austenite is created by introducing an austenite region that is attached to the ferrite region. Regions are always separated by phase interfaces and must therefore always contain different phases.

In this simulation both the FCC_A1 and BCC_A2 phases are included. Both phases are assumed to be initially homogeneous, the BCC phase having 0.01 mass-% C and the FCC phase 0.15 mass-% C. These settings are entered on the Diffusion Calculator.

As with the single phase example, the Options tab keeps all the defaults.

Add a Ferrite Region

- In the Project window, click the Diffusion Calculator node.

- Keep the default for Composition unit (Mass percent). Choose Micrometer for the Length unit. A Planar geometry is used for all the examples.

- Under Region in the Name field enter

Ferrite(replace the default text Region 1). Press <Enter>. - In the Width field enter

0.001μm and change the default number of points to10. Keep the default Automatic grid type.The grid type for the ferrite region is the same as in the single-phase simulation example, i.e. equidistant.

- From the Phase list select BCC_A2.

In the Visualizations window, the Composition Profile tab displays a preview. The initial composition profile must be specified for all regions. Since there are only two elements, Fe and C, the initial composition profile must only be given for one of them.

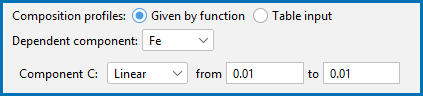

- Next to Composition profiles the default selected is Given by function. Fe is chosen as the Dependent component and the initial profile for Component C is a Linear variation.

- Enter

0.01in both fields to represent C going from 0.01 (mass-%) on the lower, left-hand side of the system to 0.01 (mass-%) on the upper, right-hand side of the system.Watch as the Composition Profile changes on the Visualizations window to match these values.

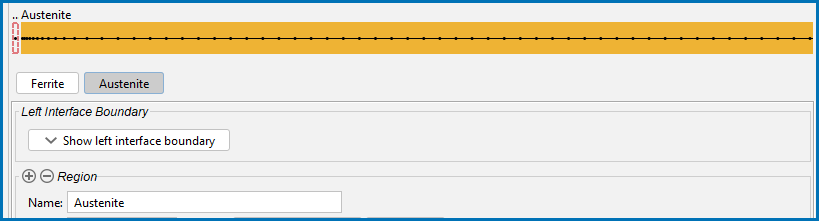

Add an Austenite Region

-

Next to Region, click the add button

. A new tab called Region 1 is added.

. A new tab called Region 1 is added.If you add a region and then need to change the order, right-click the applicable tab and choose Move left or Move right.

- In the Region Name field, enter

Austenite. This name is automatically updated on the tab and above the grid points in a new section for the second region. - In the Width field enter

2000μm. - Select a Automatic type of grid and choose Medium.

- From the Phase list, select FCC_A1.

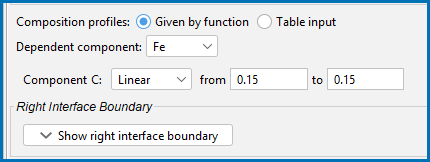

- Next to Composition profiles the default selected is Given by function and Fe is the Dependent component. Enter

0.15in both the from and to fields to represent Component C going from 0.15 (mass-%) on the lower, left-hand side of the system to 0.15 (mass-%) on the upper, right-hand side of the system. The Austenite grid shows the points and the Composition Profile changes on the Visualizations window to match these values.The domain now consists of two regions: Ferrite and Austenite.

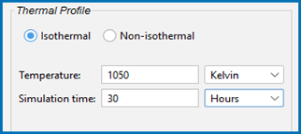

Define the Thermal Profile

The default Isothermal profile is used.

- In the Temperature field, enter

1050. Keep the default unit, Kelvin. - In the Simulation time field, enter

30. Choose Hours from the list. - Right-click Diffusion Calculator and rename it to

Diffusion two regions Ferrite and Austenite.