Solidification Simulations

Solidification is one of the most critical processes in copper alloys; it determines the formation of the bulk microstructure and then directly affects the mechanical and chemical properties of the alloys. Thus, being able to accurately simulate the solidification behavior of a copper alloy is of great importance.

With solidification simulations, the phase formation sequence, phase fraction, phase transformation temperatures, and so forth, can be predicted using Thermo-Calc and the TCS Cu-based Alloys Database (TCCU).

Scheil Solidification Simulations

A conventional Scheil simulation provides an upper boundary for how far a solidification can deviate from equilibrium, therefore a real solidification is expected to occur between the equilibrium simulation and the Scheil simulation.

The plot simulates both the equilibrium solidification and Scheil (non-equilibrium) solidification of a Cu-5.2 wt.%Sn-4.7wt.%Pb alloy. The calculated Scheil solidification path, including the solidified phases and the phase transformation temperatures, agrees well with the experimental data [2009Kor].

Read more about Scheil Solidification Simulations on our website, including how to select the right model for your simulation. If you are in Thermo‑Calc, press F1 to search the help to learn about using Scheil.

Figure 1: Equilibrium solidification and Scheil solidification simulations of Cu-5.2 wt.%Sn-4.7wt.%Pb alloy, compared with experimental result [2009Kor]. The calculated Scheil solidification path, including the solidified phases and the phase transformation temperatures, agrees well with the experimental data.

Microsegregation Simulation

Microsegregation occurs from solute partitioning during solidification processes. In addtion to causing an inhomogenous microstructure, microsegregation can cause the formation of phases that were not predicted on the equilibrium phase diagram, which could lead to defects or undesirable mechanical properties.

Using both the TCS Cu-based Alloys Database (TCCU) and TCS Cu-based Alloys Mobility Database (MOBCU), the microsegregation process in copper alloys can be modeled using the Add-on Diffusion Module (DICTRA).

Read more about the Diffusion Module (DICTRA) on our website. There is also a Getting Started with the Diffusion Module (DICTRA) page available. If you are in Thermo‑Calc, press F1 to search the help to learn about the available settings included with the Add-on Module.

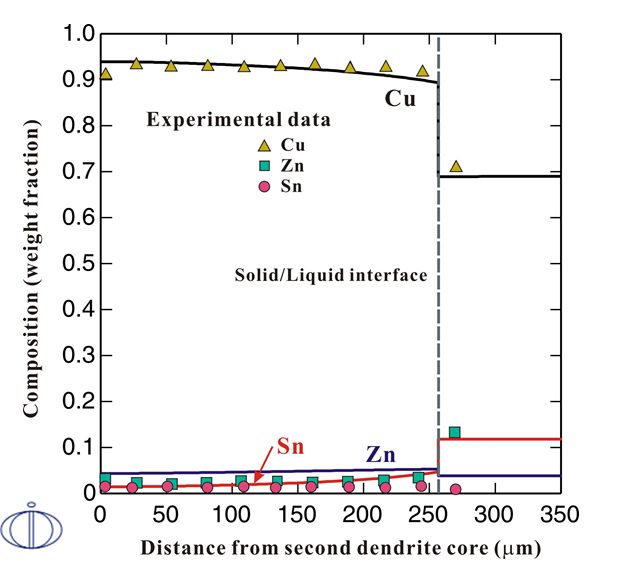

In this example, the microsegregation behaviors of Cu-4.9wt.%Pb-5.2wt.%Sn-4.5wt.%Zn during the solidification was predicted in a Diffusion Module (DICTRA) solidification simulation. The concentration of solute Sn and Zn increases from the central to the edge of the dendrite in Cu-4.9wt.%Pb-5.2wt.%Sn-4.5wt.%Zn alloys, while that of Cu shows a decreased trend.

Figure 2: Calculated composition profile through half dendrite cross section in Cu-4.9wt.%Pb-5.2wt.%Sn-4.5wt.%Zn alloy during the solidification process along with experimental data [2009Kor]. The cooling rate is 0.16 °C/s.

References

[2009Kor] B. Korojy, L. Ekbom, H. Fredriksson, Microsegregation and Solidification Shrinkage of Copper-Lead Base Alloys. Adv. Mater. Sci. Eng. 2009, 1–9 (2009).

[2018Tan] Y. Tang, Q. Chen, A. Engström, Kinetic simulations of diffusion-controlled phase transformations in Cu-Based alloys, In L.J. Zhang (Ed.), Modeling of diffusion-controlled phase transformation in alloys, Diffusion Foundation, Tans Tech Publications Ltd, 2018, pp. 1-22.

![Equilibrium solidification and Scheil solidification simulations of Cu-5.2Sn-4.7Pb alloy, compared with experimental result [2009, Korojy]. The calculated Scheil solidification path, including the solidified phases and the phase transformation temperatures, agrees well with the experimental data. Equilibrium solidification and Scheil solidification simulations of Cu-5.2Sn-4.7Pb alloy, compared with experimental result [2009, Korojy]. The calculated Scheil solidification path, including the solidified phases and the phase transformation temperatures, agrees well with the experimental data.](../../../resources/images/tccu/solid-scheil-cusnpb.png)