Blowhole Formation

The TCS Steel and Fe-alloys Database (TCFE) can be used to simulate the conditions for continuous casting of non-vacuum treated killed and semi-killed steels.

Semi-killed steels are known to be prone to blowhole formation due to the segregation of carbon monoxide, oxygen, and hydrogen.

|

|

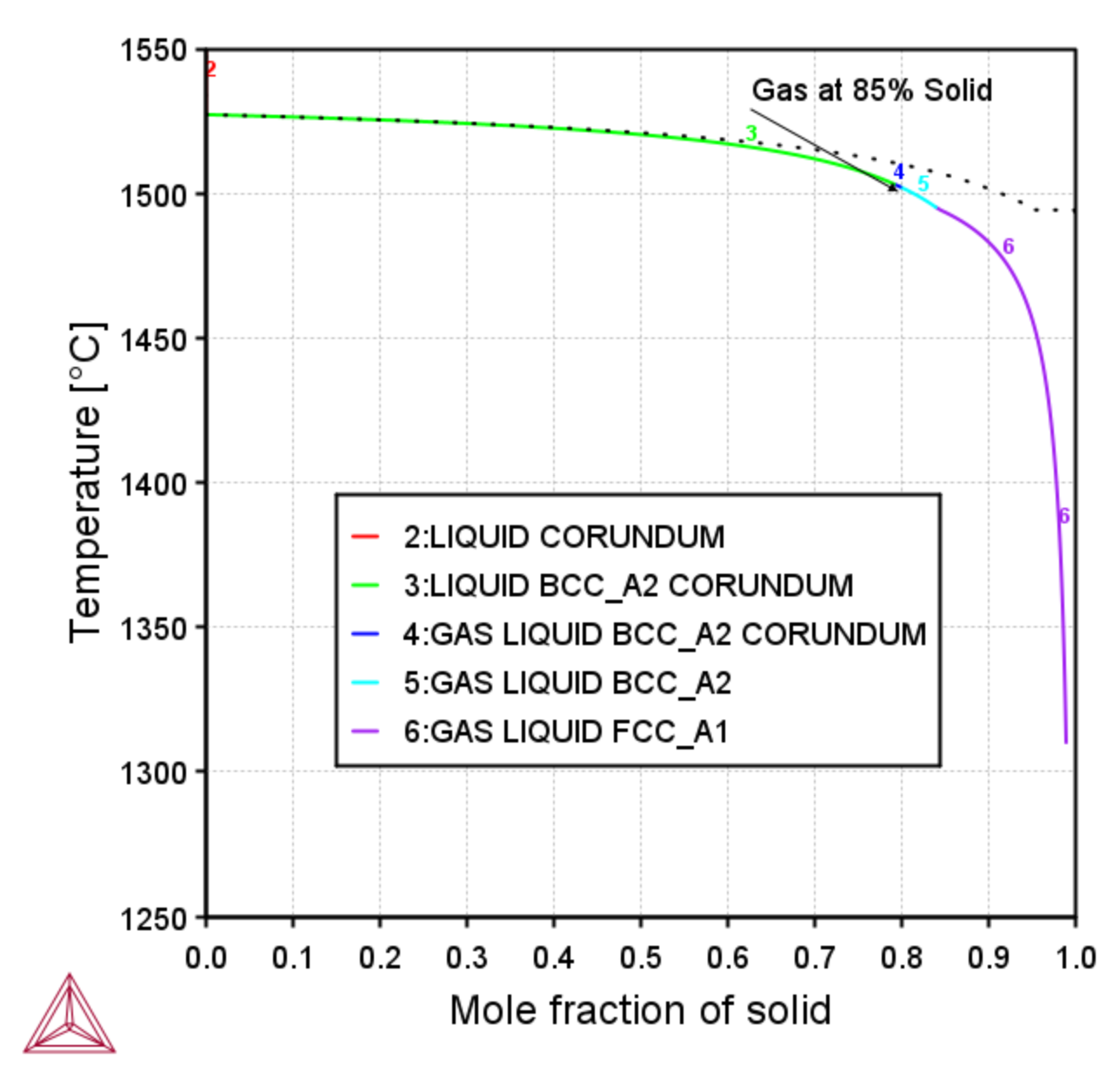

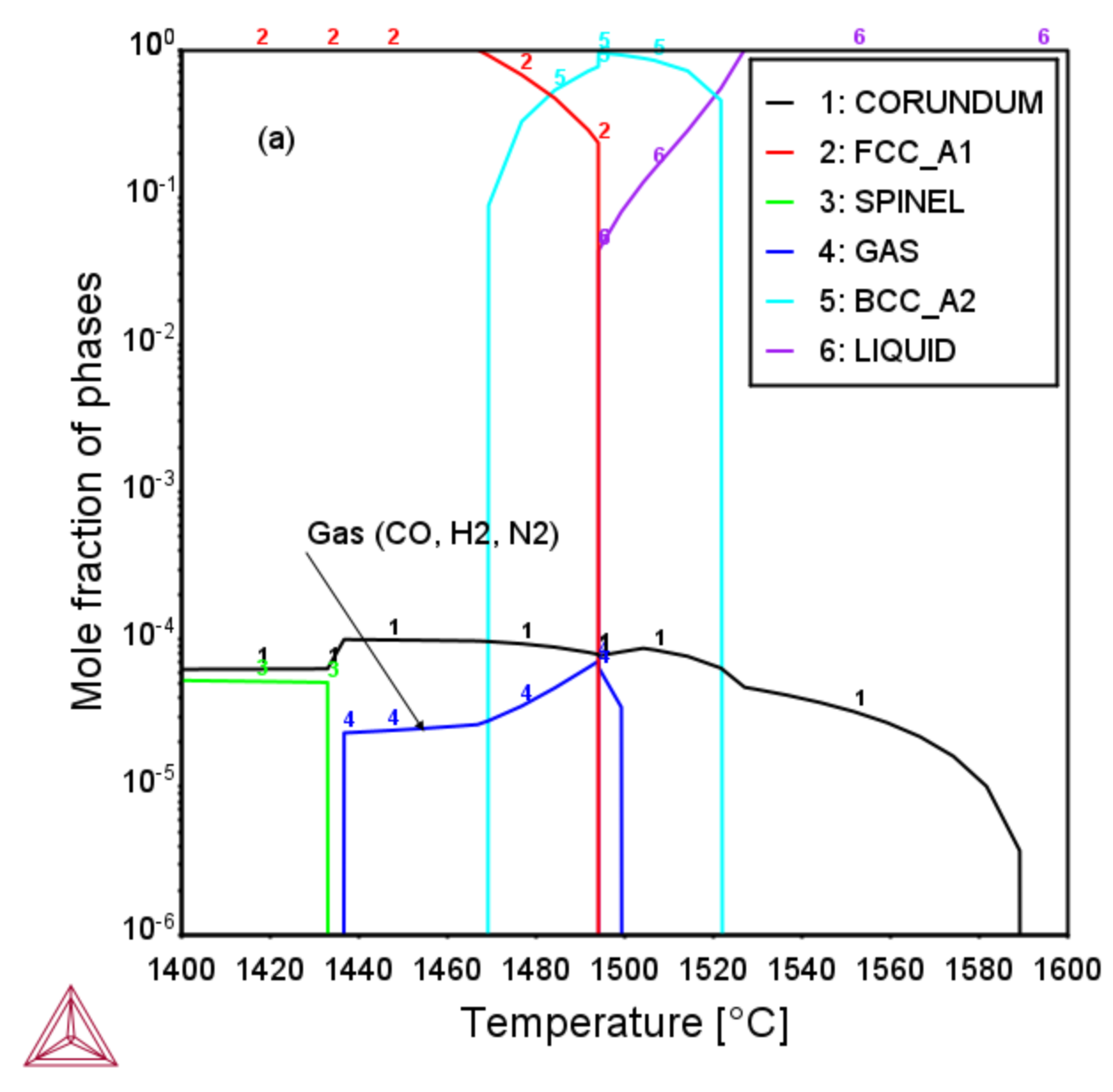

Figure 1: Equilibrium solidification of an AISI1012 alloy (Mn-Si semi killed) Fe-0.4Mn-0.1C-0.01Si with 5ppm H, 20ppm O, 70 ppm N and a) 20 ppm Al b) 30 ppm Al. Addition of Al can reduce the blowhole formation probability.

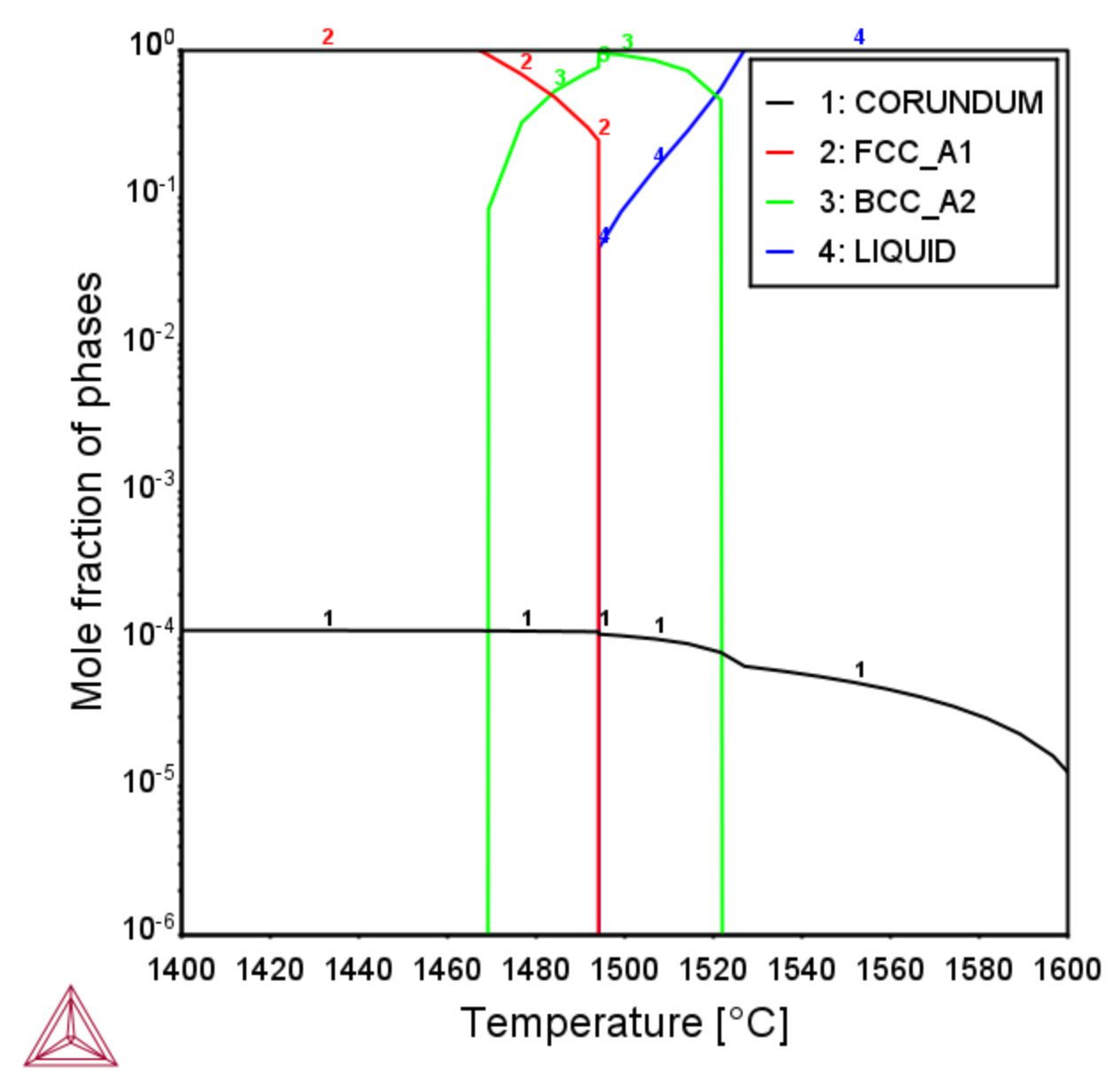

Figure 2: Scheil solidification of an AISI1012 alloy (Mn-Si semi killed) Fe-0.4Mn-0.1C-0.01Si with 5ppm H, 20ppm O, 70 ppm N and 30 ppm Al. In Scheil solidification conditions addition of 30ppm Al is not enough to prevent the blowholes when nitrogen and hydrogen are present in the steel.

Read more about Scheil Solidification Simulations on our website, including how to select the right model for your simulation. If you are in Thermo‑Calc, press F1 to search the help to learn about using Scheil.