Hot Component Application of Mg–Sn–Sr Alloys

Improving high-temperature properties of Mg-based alloys is crucial for hot component applications. Among these, Mg–Sn–Sr alloys show strong potential for enhanced creep resistance. This is primarily due to the beneficial effects of Sn and Sr: Sn contributes to grain refinement, improves corrosion resistance, and forms the thermally stable Mg₂Sn phase. Similarly, Sr also refines grains and forms several stable intermetallic compounds—Mg17Sr2, Mg23Sr6, Mg38Sr9, Mg2Sr—due to its low solubility in Mg. Furthermore, Sr and Sn can combine to form MgSnSr, another thermally stable intermetallic phase.

RE elements such as Ce, Y, and Gd can further improve mechanical properties. Yang et al. [2014Yan] found that adding 1% Ce, Y, or Gd to Mg–3Sn–2Sr (all wt.%) refined coarse MgSnSr phases, enhancing tensile and creep performance. Moreover, Ce provided the highest tensile strength, and RE-specific intermetallics—Mg12Ce, MgSnY, and GdMgSn—were observed.

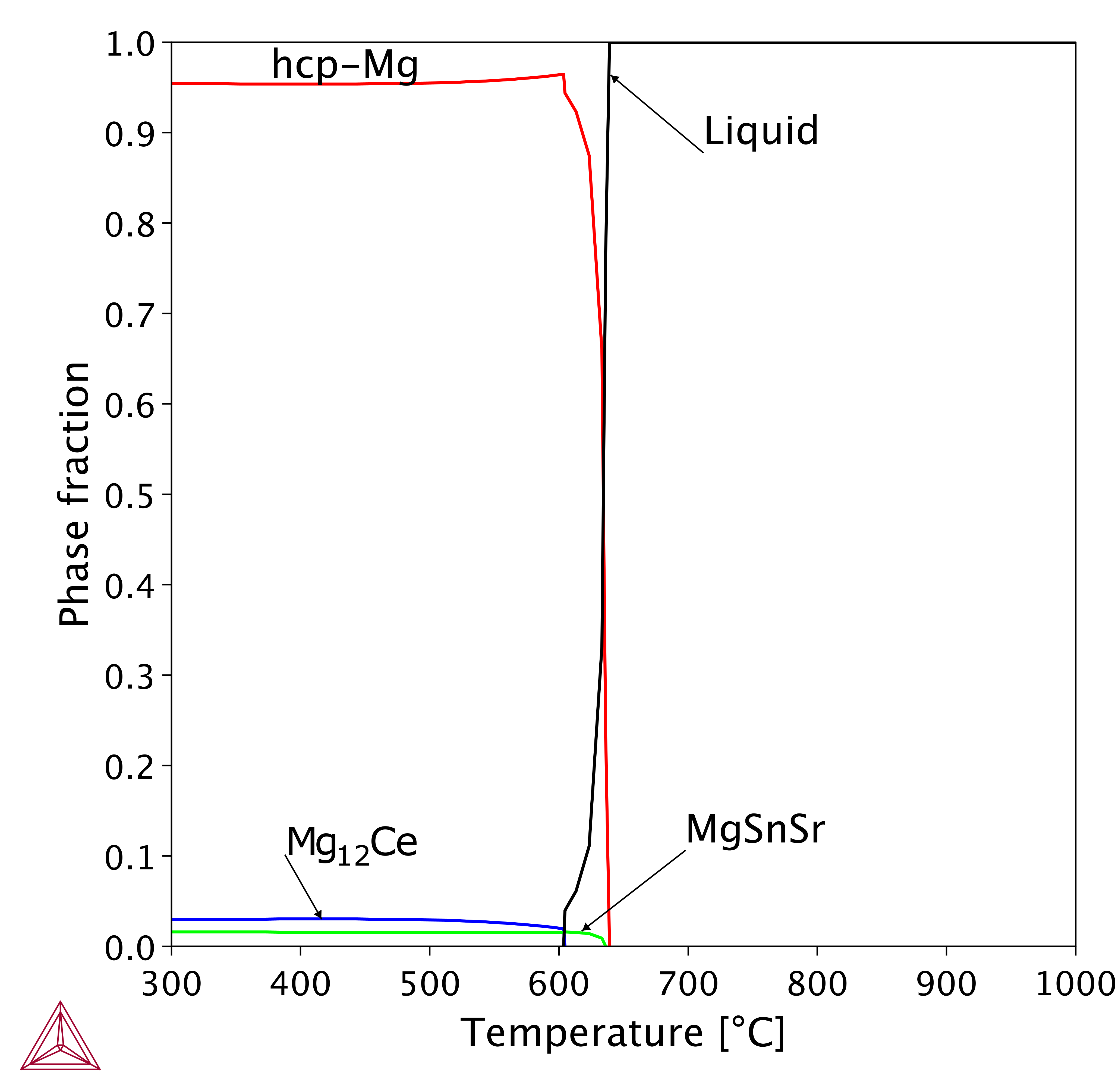

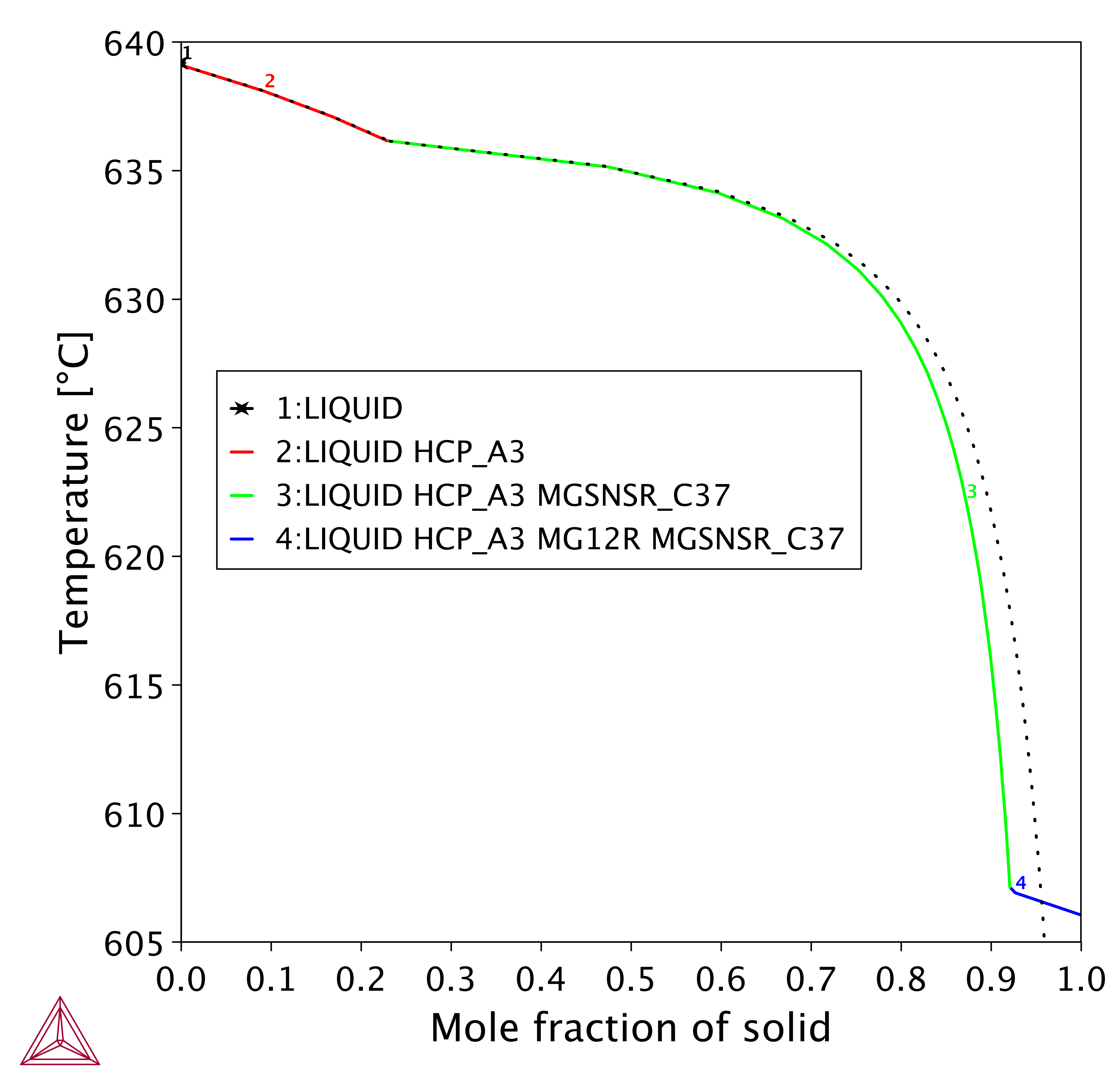

Fig. 1 shows the phase fraction calculation of the Mg–3Sn–2Sr–1Ce alloy using the latest version of TCS Mg-based Alloys Database (TCMG). The existence of all predicted phases are confirmed by Yang et al. [2014Yan]. Fig. 2 shows the Scheil solidification simulation of the same alloy using the same database. The figure shows that after hcp-Mg solidification, MgSnSr begins to form between 635 °C and 607 °C. In the last stage, remaining liquids transforms to the Mg12Ce intermetallic phase.

Reference

[2014Yan] M. Yang, M. Hou, J. Zhang, F. Pan, Effects of Ce, Y and Gd additions on as-cast microstructure and mechanical properties of Mg-3Sn-2Sr magnesium alloy. Trans. Nonferrous Met. Soc. China 24, 2497–2506 (2014).