Precipitation in Mg-Nd Alloys

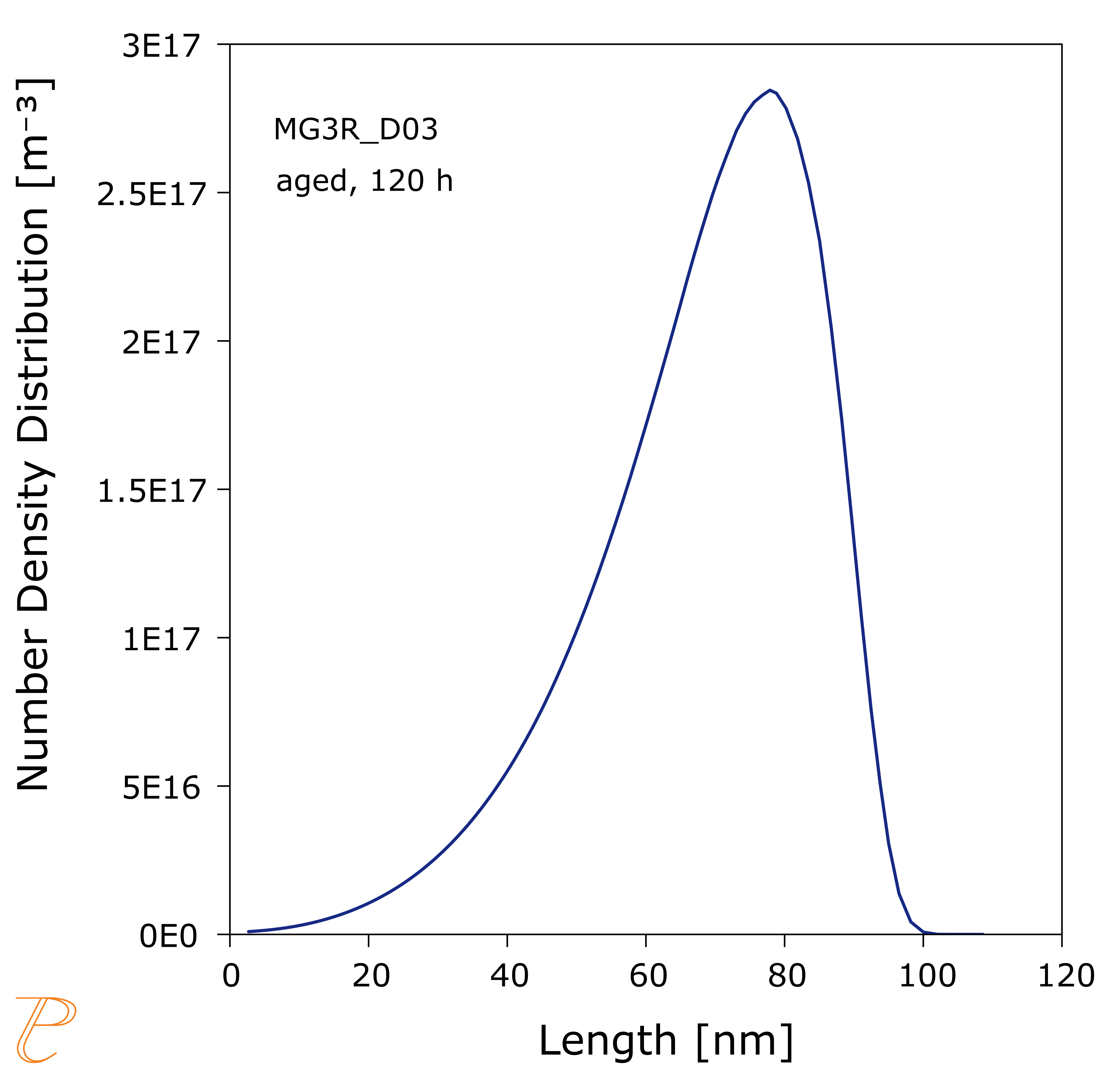

The use of the TCS Mg-based Alloys Database (TCMG) with the Add-on Precipitation Module (TC-PRISMA) enables you to do more in depth analysis of such properties as interfacial energy and particle size distribution (PSD).

Important stable and metastable precipitates have been modeled in Mg-RE (rare-earth) alloys. Especially, the bco-type Mg7RE phase, the D03-type Mg3RE phase and the D019-type Mg3RE phase (RE = Gd, Nd, Y) are modeled.

It is worth noting that whether or not a precipitate is considered metastable depends on the system and the composition. For instance, the MG3R_D03 phase can be a stable phase in the Mg-Nd binary system. When it precipitates in Mg-rich alloys, however, it is considered metastable because eventually it transforms to more stable compounds in this compositional region.

The designations of the precipitates in Mg-RE alloys are not consistent and can be confusing. Taking the Mg-Nd binary as an example, a typical sequence is β'' (D019) > β''' (Mg3-7Nd) > β'(Mg7Nd) >> β1 (D03) >> β (Mg12Nd) >> βe (Mg41Nd5). β''' (Mg3-7Nd) are translation structures between β'' (D019) and β'(Mg7Nd).

It is beneficial that these stable and metastable phases are modeled in the latest version of the database as this means you can simulate the concurrent nucleation, growth, and coarsening of precipitates during aging treatment in magnesium alloys.

Starting with version TCMG6, and coupled with a compatible atomic mobility database, such as the TCS Mg-alloys Mobility Database (MOBMG) (starting with version MOBMG2), such multi-particle precipitation simulations can be performed with the Add-on Precipitation Module (TC-PRISMA).

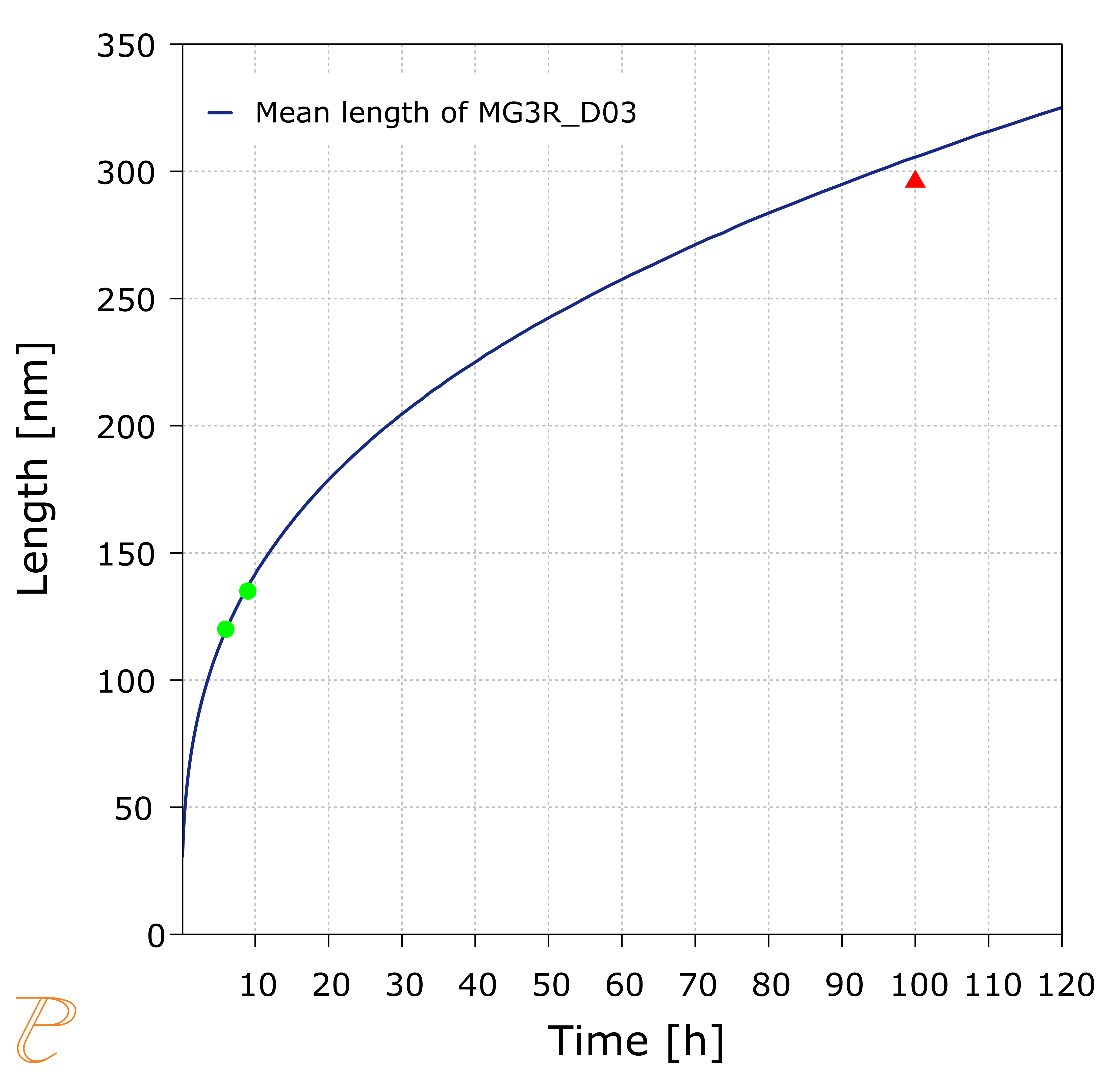

In this example, the β1-Mg3Nd (D03) precipitates are simulated as plates [2020d, Chen], where the following settings are entered on the Precipitation Calculator or determined by Thermo‑Calc:

- The aspect ratio is fixed at 13.5 according to experimental observation by [2021Hua].

- The interfacial energy is found by Thermo‑Calc as 0.029 J/m2.

- The nucleation site is assumed to be a dislocation considering the extrusion before aging.

- The density is set at the upper limit as 1E16 m-2.

- The mobility enhancement factor is set as 4 .

Read more about the Precipitation Module (TC-PRISMA) on our website. If you are in Thermo‑Calc, press F1 to search the help to learn about the available settings included with the Add-on Module.

Figure 1: Simulated length of β1 (D03) precipitation during aging of an Mg-2.4 wt.% Nd alloy at 523 K for up to 120 h.

References

[2020Che] H.-L. Chen, Modeling Mg-RE (rare earth) metastable precipitates in TCMG6, Thermo‑Calc Software (2020).

[2021Hua] Z. Huang, C. Yang, J. E. Allison, L. Qi, A. Misra, Dislocation cross-slip in precipitation hardened Mg–Nd alloys. J. Alloys Compd. 859, 157858 (2021).