Elastic Properties for FCC_A1, BCC_A2, and HCP_A3

The TCS Ti/TiAl-based Alloys Database (TCTI) (starting with version 6 (TCTI6) contains the necessary thermomechanical data for calculation of elastic constants and related elastic moduli for the three major phases FCC_A1, BCC_A2, and HCP_A3.

An example of the effect of oxygen concentration on Young’s modulus in HCP_A3 titanium is included with the Thermo-Calc installation. See T_19: Young's Modulus for Ti-O with Elastic Properties.

Pure Titanium

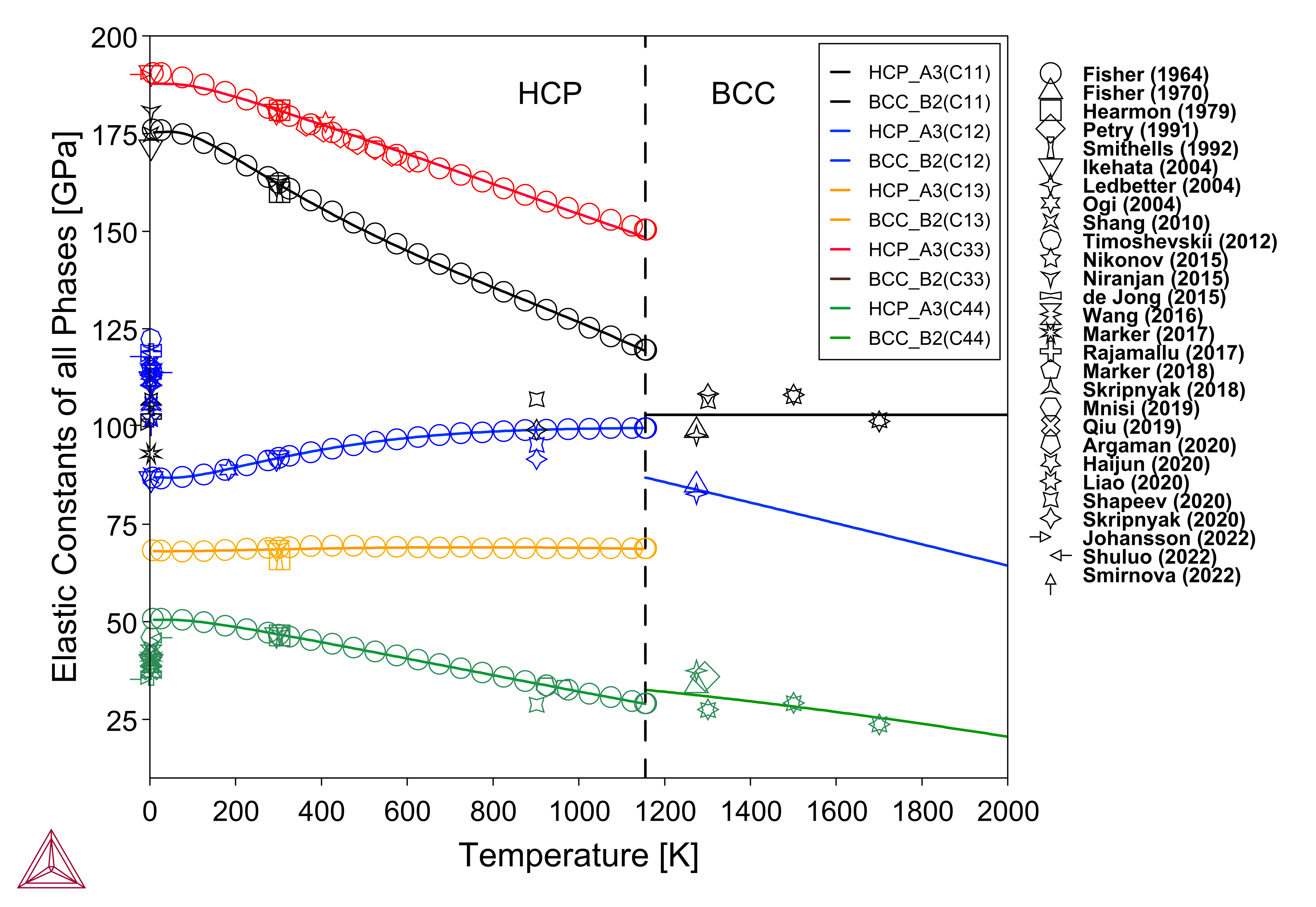

This example shows the temperature dependence of the independent elastic constants Cij of stable pure titanium. The color coding is black for C11, blue for C12, orange for C13, red for C33, and green for C44.

Figure 1: Independent elastic constants Cij of HCP_A3 and BCC_A2 titanium. Note, some data for BCC_A2 titanium is present below the transition temperature.

Literature vs Calculated Elastic Constants

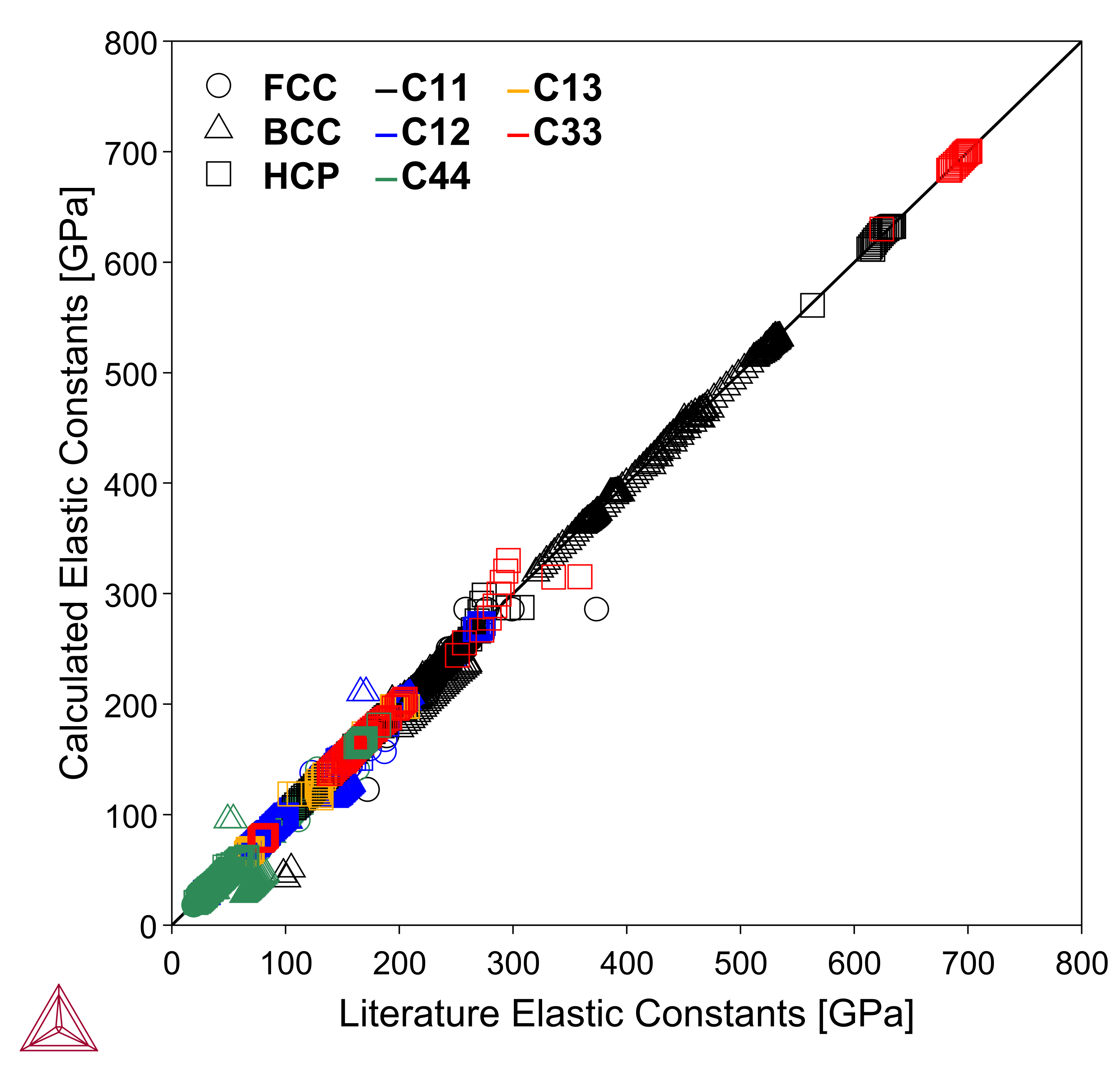

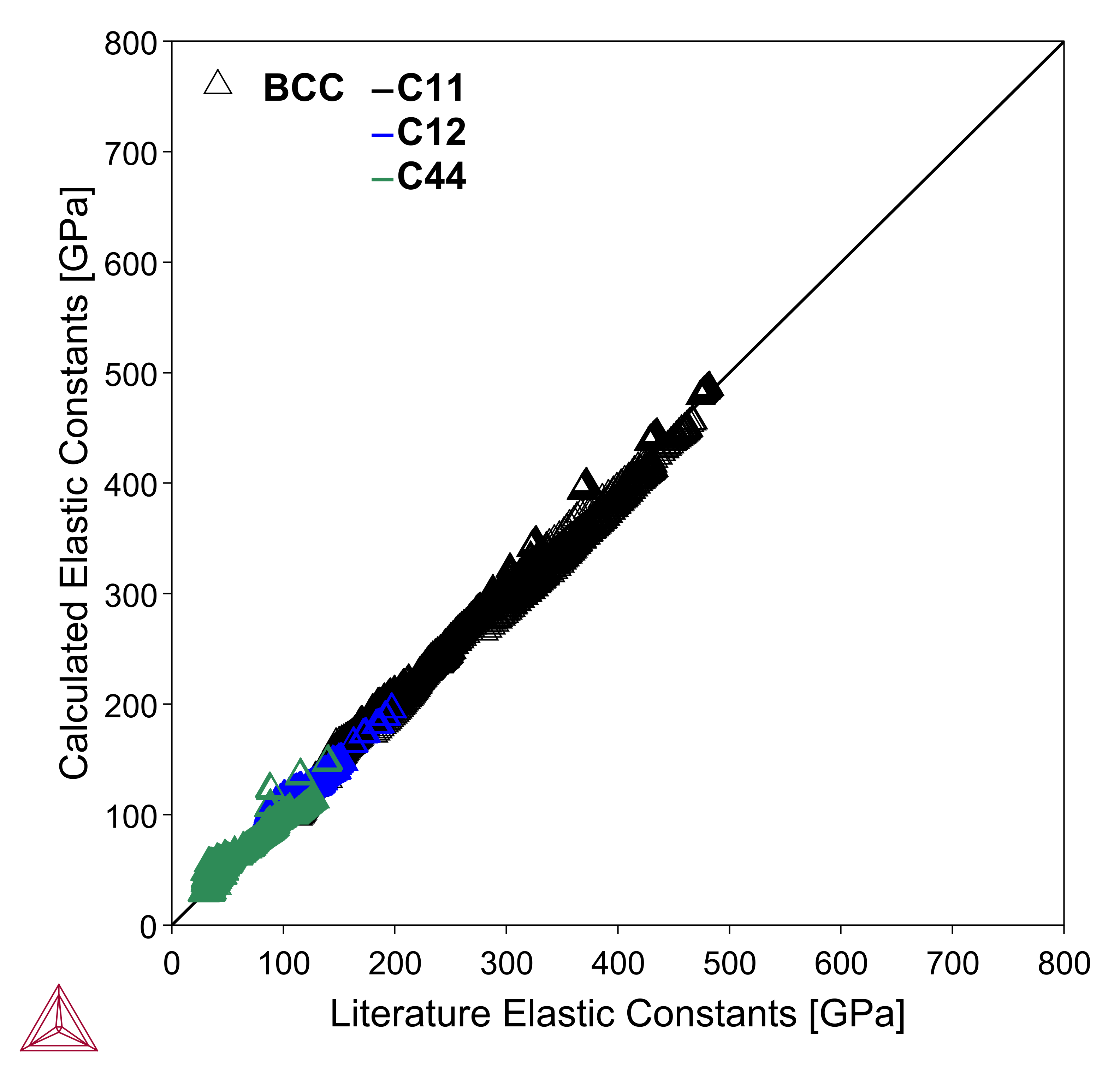

This example shows a comparison between elastic constants taken from scientific literature, both experimental and theoretical, and calculated using our CALPHAD models for the TCTI unaries in different phases at different temperatures and a wide variety of titanium binaries and other important binary systems for titanium alloys in BCC phase at different temperatures and compositions. Metastable BCC titanium alloys are commonly sought after in biomedical applications for their bone tissue compatible mechanical properties.

The black line indicates perfect agreement between calculated and literature values. Some deviations are to be expected, since the derivation of elastic constants is not straight forward, and both typical ab initio calculations and experimental measurement methods have some inherent uncertainties. Therefore, deviations of a few percent, corresponding to several gigapascals, are normal. The color coding is black for C11, blue for C12, orange for C13, red for C33, and green for C44.

Figure 2: A comparison of literature and calculated elastic constants of TCTI unaries in different phases at different temperatures.

Figure 3: A comparison of literature and calculated elastic constants of TCTI titanium binaries and other important binary systems for titanium alloys in BCC phase at different temperatures and compositions.

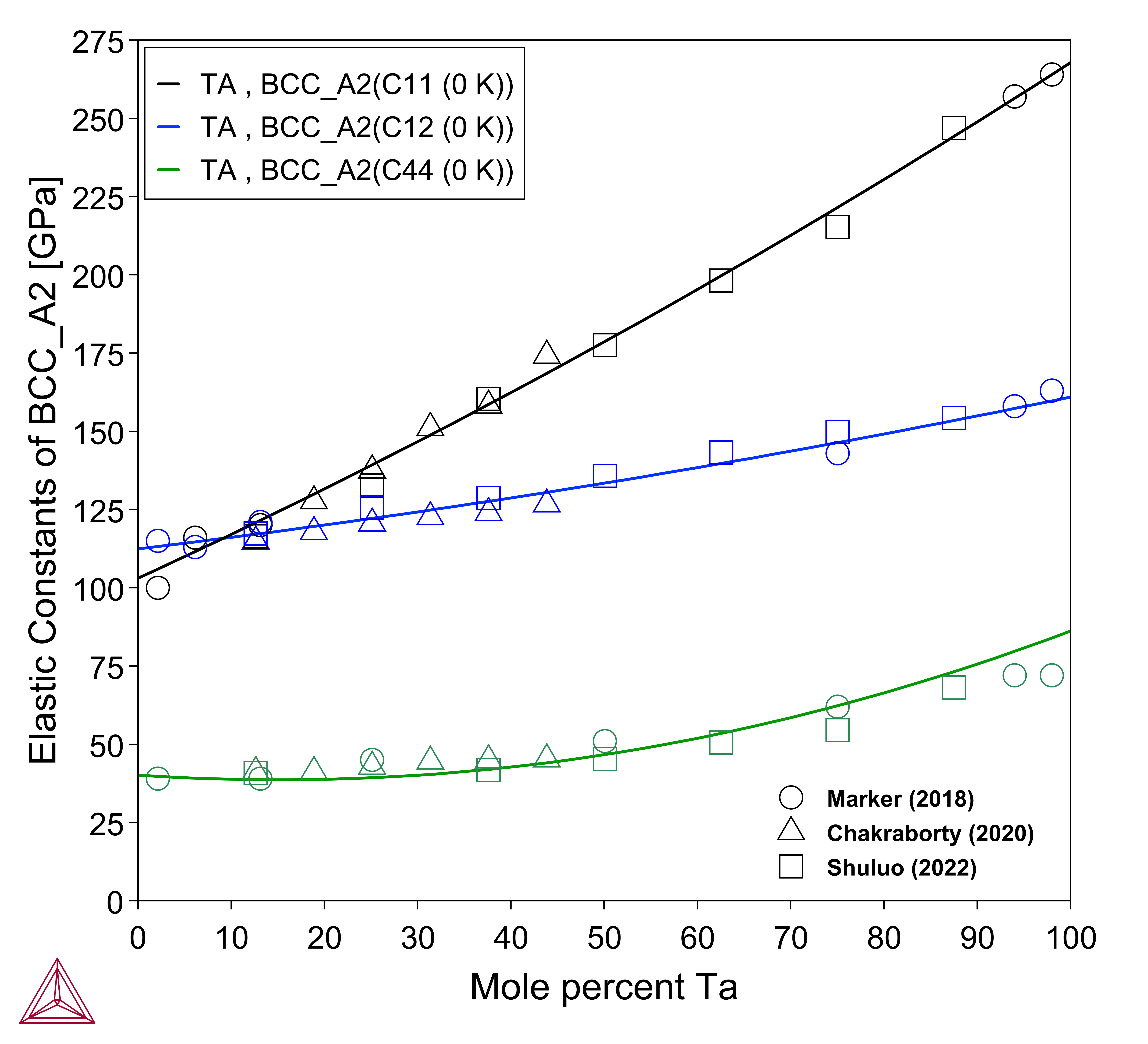

BCC_A2 Ti-Ta Alloys

Titanium alloys are successful in the field of biomedical applications due to their mechanical properties and compatibility in biological environments. Compared to commercially pure titanium, metastable BCC titanium alloys can exhibit reduced elastic moduli, more closely matching that of human bone, reducing risk of stress shielding and bone resorption. There are a number of BCC stabilizers that allow titanium alloys to exist in the BCC phase at ambient conditions, one of which is tantalum.

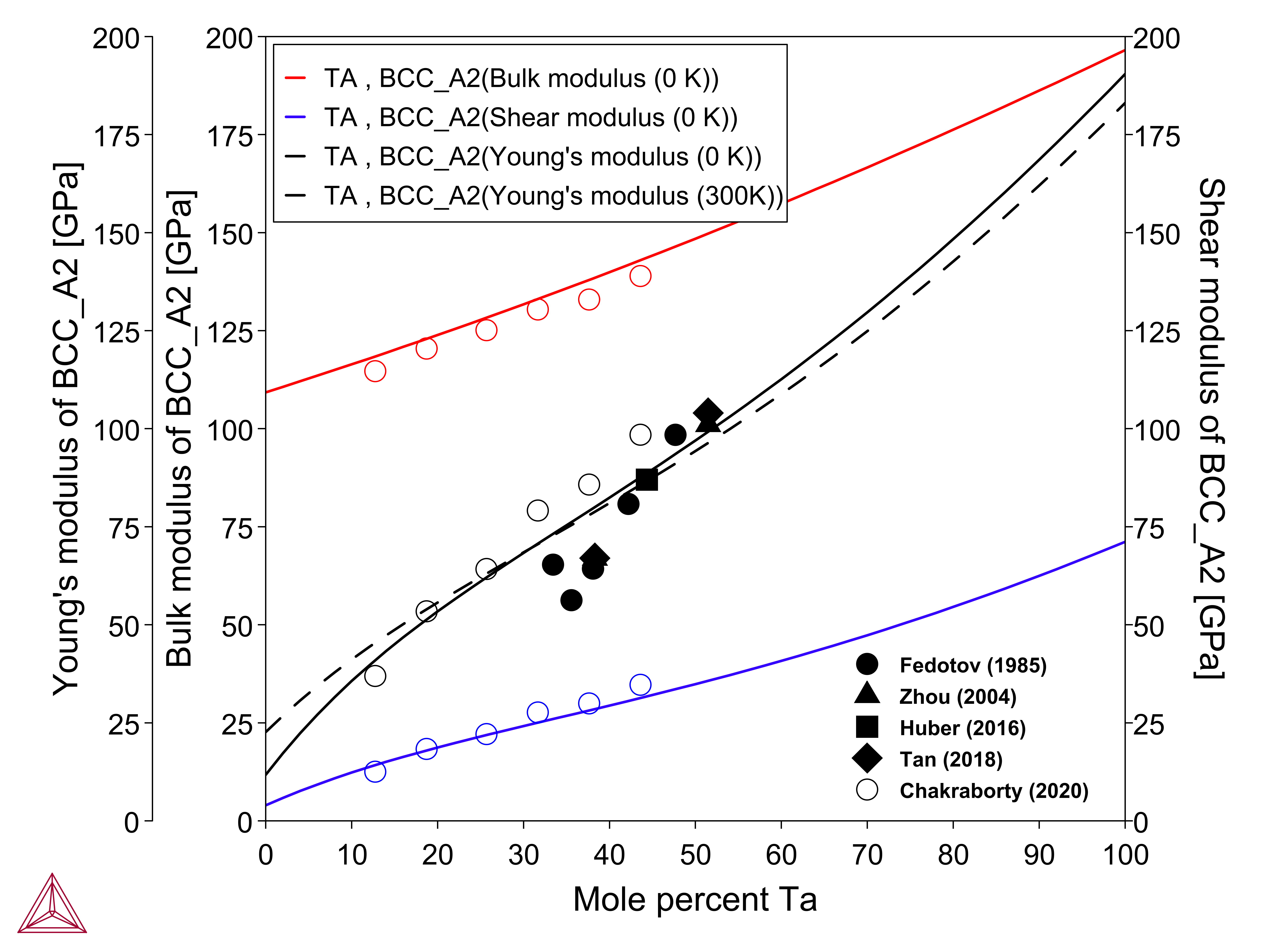

This example shows the calculated elastic constants (Figure 4) and moduli (Figure 5) of metastable BCC_A2 Ti-Ta alloys. In both figures, the literature data and calculations are at 0 Kelvin, except for the black filled symbols and corresponding dashed line. Those represent Young’s modulus values at room temperature (RT).

Only the elastic constants are assessed and then used to derive the elastic moduli, meaning the literature data in Figure 5 is standalone from the assessment work.

Figure 4: Calculated elastic constants at 0 K of metastable BCC_A2 Ti-Ta alloys. Open symbols represent DFT values from the literature.

Figure 5: Calculated elastic moduli at 0 K, with the addition of Young’s modulus measurements at RT of metastable BCC_A2 Ti-Ta alloys. Open symbols represent DFT values from the literature and filled symbols are from experiments. The dashed black line shows the calculated values of Young’s modulus at RT.