PMET_06: Ladle Furnace (LF) Kinetics

This in-depth example, which is also showcased on our website, uses the Process Metallurgy Calculator to show how to set up a full kinetic simulation of steel refining in a ladle furnace using the Process Metallurgy Module in Thermo-Calc. The Process Metallurgy Module uses the Effective Equilibrium Reaction Zone model (EERZ) to simulate the kinetics of the process. In this example, a full kinetic simulation of the LF refining process is set up using the Process Metallurgy Module.

For a simpler process that describes a lab-scale ladle furnace process, see PMET_05: Lab Scale Ladle Furnace (LF) Kinetics.

Background Overview

After steelmaking, which is mostly performed in a basic oxygen furnace (BOF) or electric arc furnace (EAF), the steel is usually tapped into a ladle where certain additions are made (deoxidation agents, slag formers, certain alloying elements) and then transferred to the ladle furnace (LF). The LF fulfils many purposes in the steel refining process, the most important being:

- Temperature control / heating by an electrical arc.

- Mixing by Ar or N2 bubbling through porous plugs in the bottom of the ladle to achieve homogeneous temperature and composition throughout the ladle.

- Removal of unwanted non-metallic phases / inclusions such as corundum (Al2O3), liquid oxide inclusions, spinel, on so on, by flotation, aided by Ar or N2 bubbling.

- Modification / engineering of non-metallic inclusions so that they are not detrimental for the downstream processing and/or the final product.

- Removal of unwanted volatile elements such as Pb, Zn, Sn, and so on. Due to their high vapor pressure, these elements are enriched in the rising Ar or N2 bubbles. After the gas escapes out of the ladle and cools, they condense, forming copious amounts of dust.

- Removal of unwanted elements such as sulphur by liquid steel / slag reactions.

- Lowering of the dissolved gas content. In the LF this is mainly achieved through chemical reactions. For direct removal of dissolved gas, vacuum degassing (VD) is usually required.

- Alloying and trimming of the steel to achieve the exact alloy composition required by the specification of the steel that is to be produced.

The reactions taking place in a LF are a complex interplay between equilibrium thermodynamics that define the direction of chemical reactions, and kinetics that define how fast the equilibrium state is approached.

- Folder: Process Metallurgy

- File name:

PMET_06_Ladle_Furnace_Kinetics.tcu

This example requires the database TCOX10 or newer, a full license of Thermo‑Calc 2020b or newer, plus a license for the Process Metallurgy Module.

Visualizations

This example is included as a Process Metallurgy tutorial on our website and as part of the playlist our YouTube channel.

Open the example project file to review the node setup on the Project window and the associated settings on the Configuration window for each node. For some types of projects, you can also adjust settings on the Plot Renderer Configuration window to preview results before performing the simulation. Click Perform Tree to generate plots and tables to see the results on the Visualizations window.

The resulting plots and details related to setting up this example are available to download via the dedicated web page.

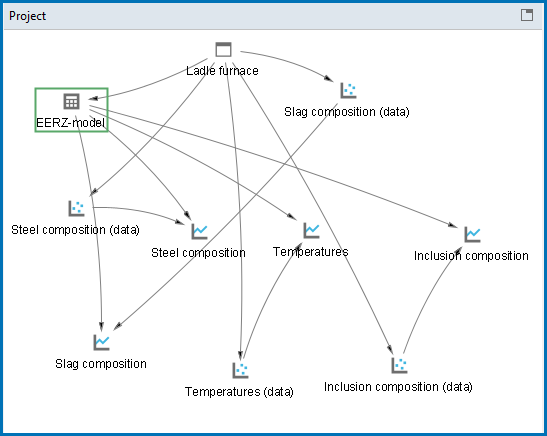

The nodes in the Project window for this example. The Process Metallurgy Calculator is renamed to EERZ model. If you click this node the Configuration window opens, which is where all the settings for the process simulation are located. This advanced example also uses three Experimental Data Reader nodes to read the experimental data that is included in the simulation results. After setting up the system and accessing the experimental data, you then add Plot Renderers to the calculator to generate the output in the Visualizations window.