Process Simulation: Process Schedule Tab

The following outlines what you can set on the Configuration window Process Schedule tab. The overall steps to set this up are described in Defining the Process Simulation. Also see Working with the Process Schedule.

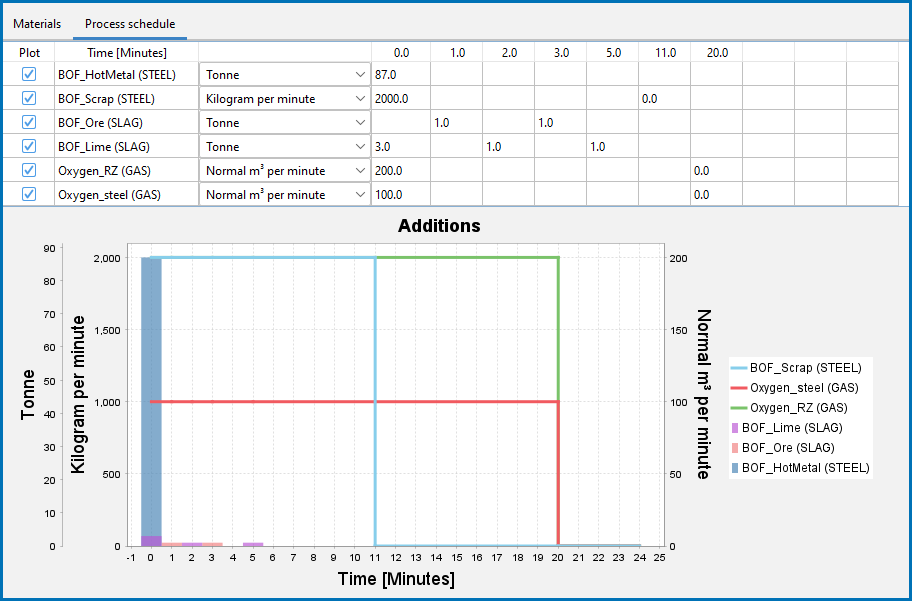

On the Process schedule tab, the sequence and amounts of additions during the duration of the process are defined. All the materials defined in the Materials tab automatically are included in the table. If a heat addition is defined in the Process Model this is also included in the table.

Select the Plot checkbox to include or exclude the components in the process schedule plot area, for example, to help you examine the changes in the plot window, after defining the Steel, Scrap, Slag, or Gas rows, see what happens when you remove one or more items from the plot.

Enter a value and choose a unit Tonne, Kilogram, Pound, Kilogram per second, or Kilogram per minute. For Gas you can also choose Normal m3 per minute as the unit.

If a unit Tonne, Kilogram, or Pound is selected, then the additions are defined as one-time additions at a certain time. If a rate is chosen as unit of the addition (such as Kilogram per minute or second, for gas Normal cubic meter per minute or second) then the rate of addition is entered into the table and it stays constant until a different value is entered.