Defining the Equilibrium Simulation

After adding a Process Metallurgy Calculator to your project, you can choose to conduct an Equilibrium simulation, where you define the steel, slag, and gas groups of materials, or a Process simulation, where you set up a process using the EERZ (Effective Equilibrium Reaction Zone) model.

The following steps are for Equilibrium simulations. If you choose to do a Process simulation, see Defining the Process Simulation.

This is a general overview of the setup based on the PMET_01: Basic Oxygen Furnace (BOF) example, which walks you through the steps that represent a simplified steelmaking process.

- Add a Process Metallurgy Calculator node to

My Projects node. If you used the Process Metallurgy template on the

My Projects node. If you used the Process Metallurgy template on the  My Projects Configuration window under Applications), click the node to display the Configuration settings window.

My Projects Configuration window under Applications), click the node to display the Configuration settings window. - Under Kinetics, choose the simulation type, Equilibrium or Process simulation. For the following steps, choose Equilibrium.

-

In the Configuration window, for the Database selection, the program automatically defaults to the highest available version of the TCOX database.

The Process Metallurgy Module requires both a valid Maintenance and Support Subscription (M&SS) and a license for the TCS Metal Oxide Solutions Database (TCOX8 or newer).

It is not possible to use custom user databases with the Process Metallurgy Module. This is because several internal calculations, such as determining the component compositions of ionic phases, are dependent on the database. Therefore, only TCS Metal Oxide Solutions Database (TCOX) versions 8 and newer, and to a limited extent, OXDEMO, can be used with this Module.

All users can test the Process Metallurgy Module with the included OXDEMO database, which is limited to these elements: Al, C, Ca, Fe, O, S, and Si. For more information about this and other products visit our website.

- Set the Thermal Control as being Isothermal or Adiabatic.

- Select a Temperature unit (Kelvin, Celsius, or Fahrenheit) and enter a numerical value in the field.

- Select a Pressure unit (Pascal, Atmospheres, or Bar) and then enter a numerical value in the field.

Next define each material group—Steel (or any user-defined Metal group), Slag, and Gas.

See Equilibrium Simulation: Conditions Tab for an overview of the layout of this section. There is also an overview of these material groups in Working with the Process Metallurgy Module.

- Choose a Material to set up first, Steel (or any user-defined metal), Slag, or Gas.

- Select an Amount from the list—Tonne, Kilogram, Gram, or Pound. Enter a numerical value in the field.

- If this is the first time you are defining a material, or at any time when User-defined is selected, click Show composition to set the composition for the material (steel, slag, or gas or another user-defined metal).

The composition for each material is hidden by default because the Module allows you to easily save materials and access these from the material menu. Once you save a collection of materials, you will rarely have to click Show composition. See Working with the Material Manager for details about saving and deleting materials.

- To the right of the Material list (e.g. for the Steel group), choose the material composition you want to use for this simulation. Predefined Example Steel and Example Slag compositions are included with the installation.

- If you chose Adiabatic as the Thermal Control, also enter a temperature in the field for each material. This is the initial temperature before the material is added to the process.

- From the first Input type list select Mass percent, Mass fraction, Mole percent, Mole fraction, or Absolute amount. For Absolute amount, you can directly enter values in the fields in the unit selected above for Amount (Tonne, Kilogram, Gram, or Pound).

- For the next list, the default is based on which group you are defining. For the Steel (Metal) group it is Element, for Slag it is Component, and for Gas it is Gas component.

- Choose Major component so that as you add other components, the major one is adjusted to be the rest of the composition. Choose Normalize to total of 100% so that the sum is adapted to 100%. This is useful if you need to work with a given composition that does not sum up to 100% If you select Absolute amount, Normalize to total of 100% is not available.

- Based on which material group you are working with, add the Element, Component, or Gas component.

To add one or more material groups click the add  button. Click the minus

button. Click the minus  button to remove a material group. The new material inherits the default settings of that group.

button to remove a material group. The new material inherits the default settings of that group.

- After you have added and defined the element, component, or gas component it is recommended you save and name the material. This makes it easier to work with because the name of the material is automatically updated in the lists (and available as part of your library) instead of being named User-defined everywhere.

The material is automatically saved in the relevant material group, so only steel materials are shown in the steel menu, only slag materials are shown in the slag menu, and only gas in the gas menu. You can also create additional material groups if there are groups you use regularly, such as scrap compositions, ferro-alloys or slag additions. See Working with the Material Manager for more details about creating and deleting material groups and deleting materials.

- Continue adding and defining the material groups (e.g. Steel, Slag, and Gas). You could, for example, add another Steel group if you wanted to define a composition of a steel scrap to add to a basic oxygen furnace (BOF).

These settings are described more in Equilibrium Simulation: Conditions Tab.

- Under Calculation Type, click to choose Single (no axes), One Axis, Grid, or Uncertainty.

For more complex calculations, it is good practice to start with a Single equilibrium calculation to make sure the calculation converges. Also see the settings described in Process Metallurgy Calculator: Options Tab. These can be useful if your calculation fails.

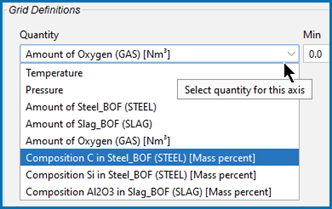

- Based on the calculation type, define either the Grid Definitions (for One Axis or Grid calculations) or the Sampling of Data from Gaussian Distributions (for Uncertainty calculations). The Quantity displays all the stepping options set up with the material groups for Steel, Slag, and Gas. The example shows the steel group quantities.

The Amount of X in Y quantities you can choose from the various drop-down lists (such as under Grid Definitions) are defined as Min-Max variation of the component X in Y. If a dependent element is present that is adapted as usual.

How these quantities relate to the material definition is described in Working with the Process Metallurgy Module.

Once you have finished defining the Process Metallurgy Calculator, you also define the plot or table settings. To add a Plot Renderer or Table Renderer, right-click the calculator node and select an option from the Create New Successor menu.

The settings are generally described for the individual nodes. See Plot Renderer and Table Renderer. Some useful information about the plots is also described in Working with the Process Metallurgy Module.