Simulating a Scheil Solidification Process

About the Scheil-Gulliver Solidification Simulations

Simulating a Scheil-Gulliver solidification process involves calculating the liquid composition of a higher-order multicomponent system at each step of a cooling process, and resetting the liquid composition as the composition of the entire system (after having removed all amount of solid phase).

The step-by-step instructions below are intended as a simple example of setting up a calculation using the wizard in Console Mode. You can also use the macros available and briefly described in Scheil-Gulliver Examples.

The following does not include any prompts related to using back diffusion or solute trapping. See START_WIZARD for additional details about when these options are enabled with the USE_BACK_DIFFUSION and SOLUTE_TRAPPING commands.

- At the prompt type goto_module scheil.

- Type Start-Wizard and press <Enter>.

- Specify which

Databaseto use. Type?for a list of available databases based on your license.- Type

FEDEMOfor this example.

- Type

- Specify the

Major element or alloyin your system. For example, enterFe(steel/Fe-alloy),Al(Al-based alloy), orNi(Ni-based super alloy).- Type

Fefor this example.

- Type

- Set whether to specify the

Composition input in mass (weight) percent(the default) or inMole percent. Press <Enter> to keep the default for mass (weight) percent or typeNto use mole percent.- Keep the default for this example (press <Enter>).

- Specify the name of the

1st alloying element. You can directly specify mass or mole percent after the name. If this is not specified, then you are prompted to enter it separately.- Type

Cr 5for this example.

- Type

- Specify the other alloying elements in the same way as you specify the first.

- Type

C 1for this example.

- Type

- After you have specified your last alloying element, press <Enter>. This ends the process of defining the bulk composition of the alloy system.

You can also specify all the alloying elements and their corresponding compositions on the same line when you are prompted to specify your first alloying element. As a general example, you can enter

Cr 5 Ni 1 Mo 0.5 C 0.01 N 0.02.- Press <Enter> for this example.

- Specify the starting

Temperature (C)in Celsius. The default is2000.This value should be sufficiently high so that the solidification simulation starts with the alloy system in the liquid single-phase region.

- Keep the default for this example (press <Enter>).

- At the

Reject phase(s)prompt enter the name of the phases to reject or press <Enter> for the defaultNONE.- Keep the default s for this example (press <Enter>).

- At the

Restore phase(s)prompt you may want to restore a phase that you rejected when you ran the simulation earlier, or you may want to restore a phase that is rejected by default in your database. Enter the name of the phases to restore or press <Enter> for the defaultNONE.- Keep the default for this example (press <Enter>).

- When prompted

OK?typeNto go back to reconsider which phases to reject or restore. TypeYto continue. The thermodynamic data about the alloy system you defined is retrieved from the database.- Keep the default for this example (press <Enter>).

- At the

Should any phase have a miscibility gap checkprompt, press <Enter> for the defaultNor typeYthen specify thePhase with miscibility gap.- For this example, type

Ythen enterFCCas thePhase with miscibility gap.

- For this example, type

- If you answer

Yto the miscibility gap check, then next enter the following forMajor constituent(s) for sublattice 1andMajor constituent(s) for sublattice 2.- Enter

Crfor sublattice 1 andCfor sublattice 2 in this example. Then at thePhase with miscibility gapprompt press <Enter>. The system responds withLIQUID PHASE NAME: LIQUID.

- Enter

- Specify the names of any

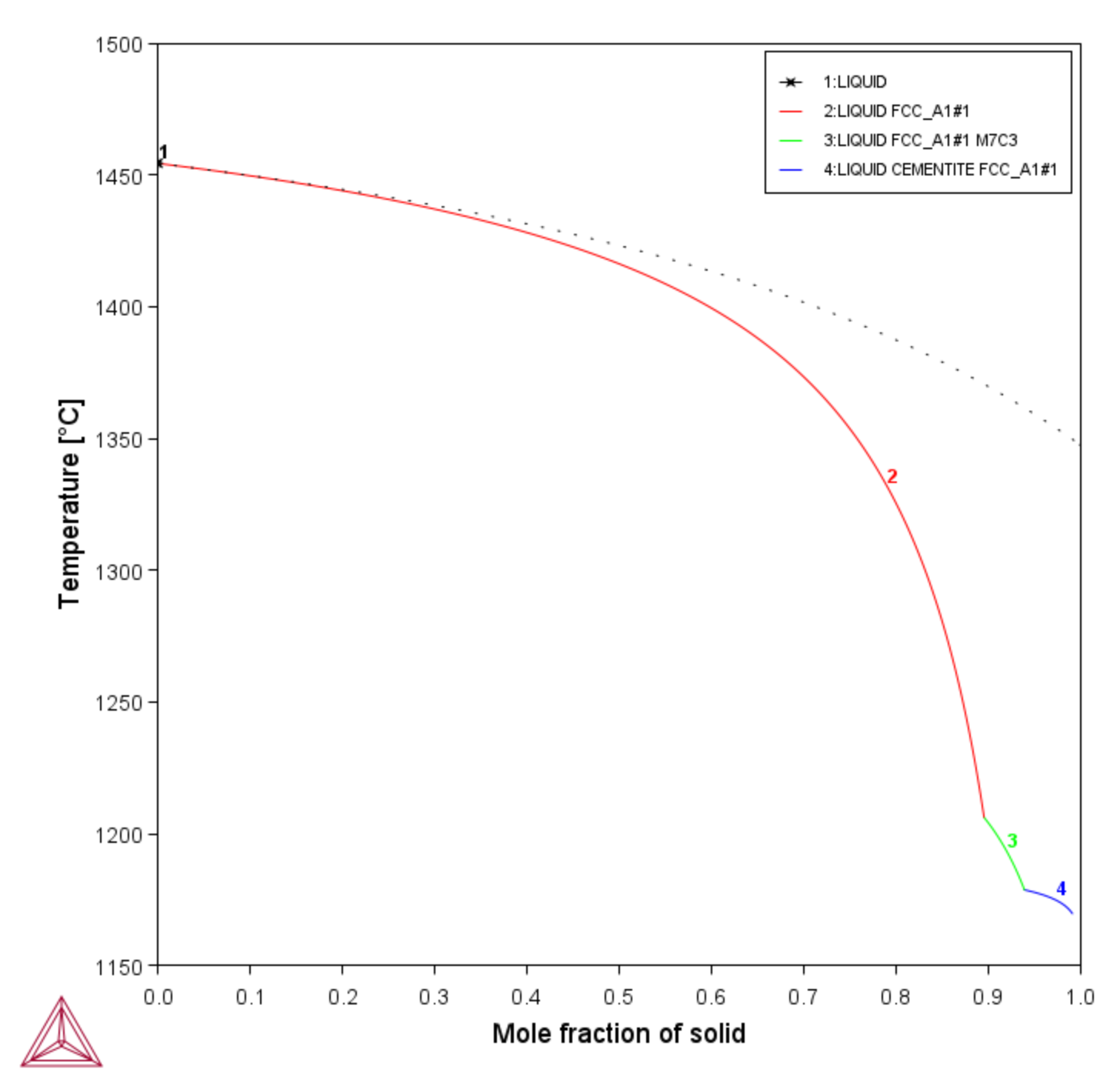

Fast-diffusing components. Press <Enter> forNONEor type all the names on the same line then press <Enter>. Keep the default for this example (press <Enter>).After the Scheil-Gulliver solidification simulation runs, the diagram Temperature versus Mole Fraction of Solid is plotted in the Console Results window.