AM Calculator Heat Source Settings

These settings are found on the AM Calculator Conditions tab. The other settings are described in AM Calculator Conditions Settings.

Choose the heat source model: Gaussian, Core-ring, Top-hat, Double ellipsoidal, or Conical. When available you can also choose predefined Users heat sources from the list.

For background theory related to Heat Sources, see About the Heat Source Models and About the Absorptivity Model. For Gaussian, Double ellipsoidal, and Conical heat sources, also see About Heat Source Calibration for additional details.

When a Users heat source option is available to choose in the heat source list, then only the Power of the heat source needs to be entered and the rest of the parameters, including the absorptivity, are automatically included in the simulation based on the selected expressions when originally saving the heat source calibration data.

The Core-ring and Top-hat heat sources are not available with Heat Source Calibration calculations.

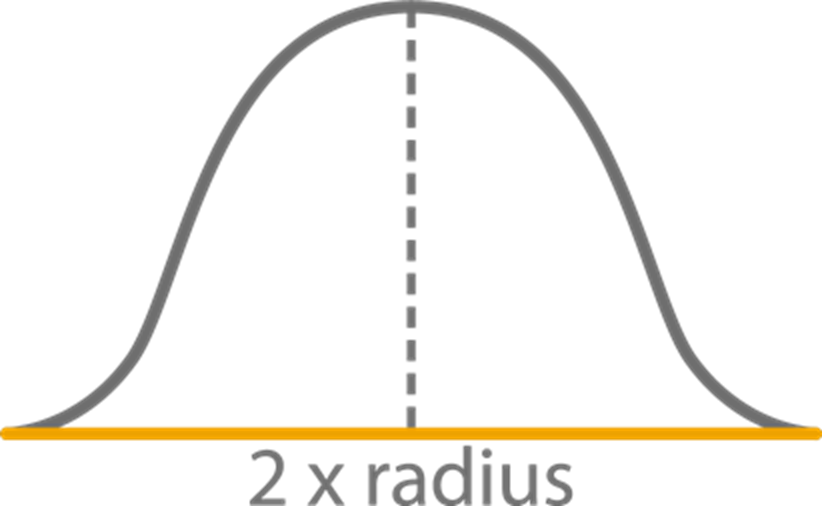

Gaussian Heat Source

Gaussian is a surface heat source, and it is applied to the top surface of the domain. Then the heat is diffused based on the diffusivity of the material. This is most commonly used heat source in the industry.

-

Settings below: Power, Absorptivity (incl prefactor, Wave length), Beam radius, Use keyhole model, Beam quality factor M2.

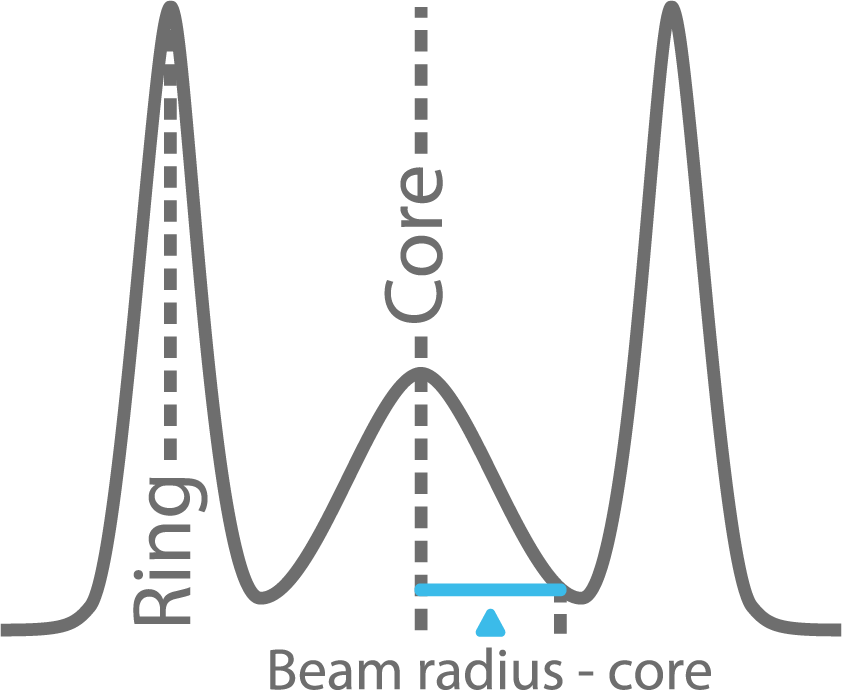

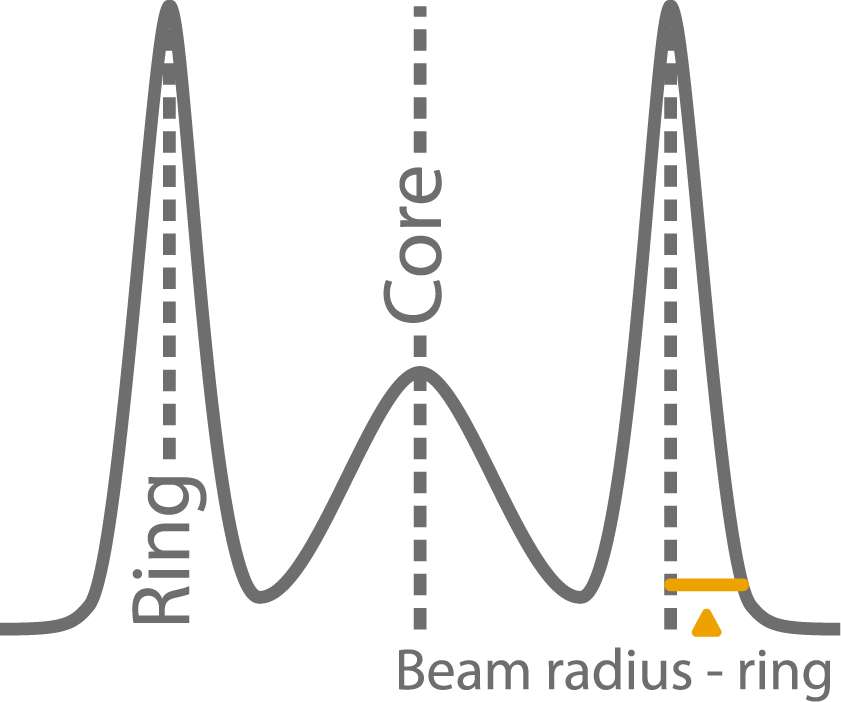

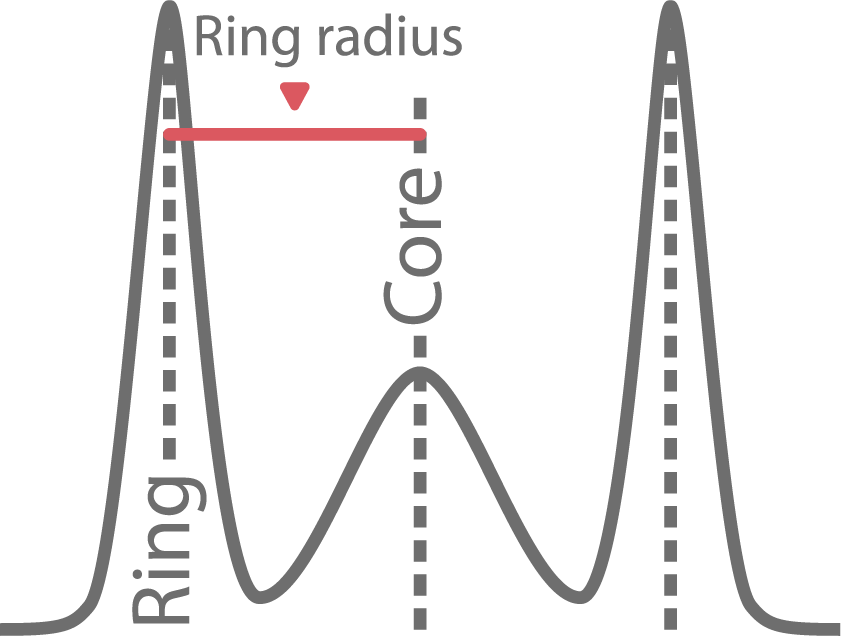

Core-ring Heat Source

A Core-ring heat source, like a Gaussian heat source, is a surface heat source model which means that the power input from the heat source is only defined on the top surface of the workpiece, as a Neumann boundary condition. The intensity of a core-ring heat source can be modeled as a combination of a central Gaussian core beam and an outer ring beam.

-

Settings below: Power, Absorptivity (incl prefactor, Wave length), Beam radius-Core, Beam radius-ring, Ring radius, Amount of power in ring, Use keyhole model, Beam quality factor M2, Mode (Index or Custom).

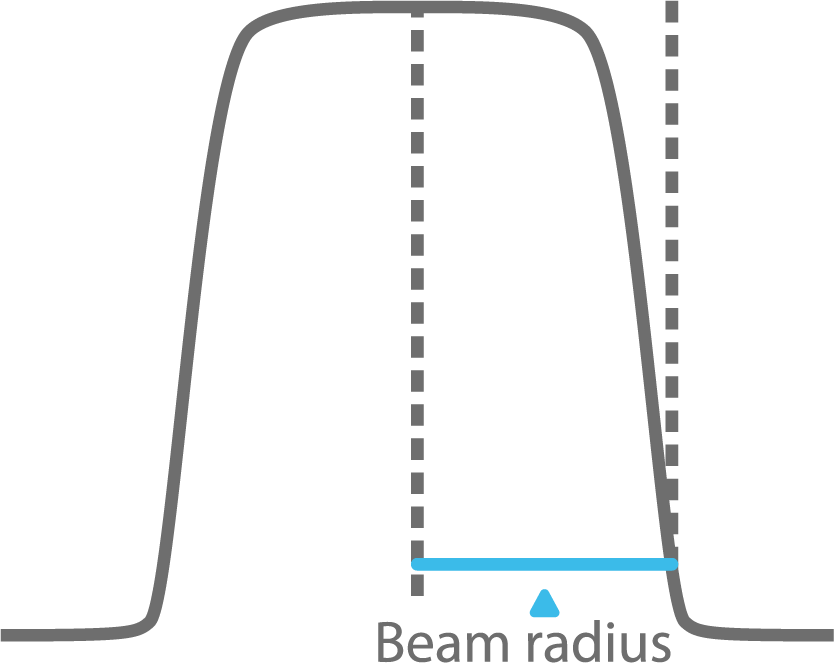

Top-hat Heat Source

A Top-hat heat source is also called a flat-top and is considered a surface heat source model. In the AM Module, the top-hat heat source is approximated with a super-Gaussian beam, which means that the intensity drops to zero gradually within a given distance.

-

Settings below: Power, Absorptivity (incl prefactor, Wave length), Beam radius, Use keyhole model, Beam quality factor M2, Mode (Index or Custom).

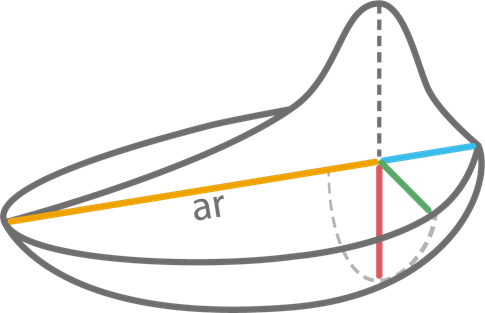

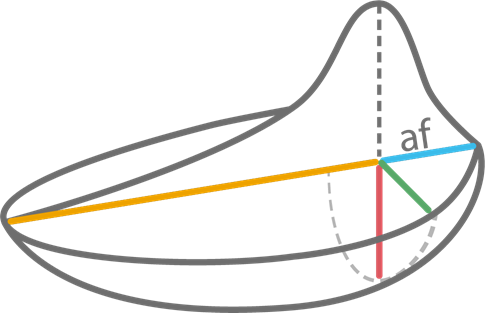

Double Ellipsoidal Heat Source

The Double ellipsoidal heat source, also referred to as Goldak, is a volume model where the heat intensity is in the front and the back of the heat source is defined with the help of two different ellipsoids. The axis of the each ellipsoid is needed.

-

Settings below: Power, Absorptivity (% only), ar, af, b, c.

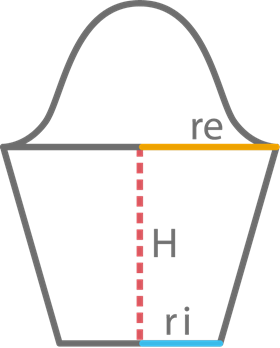

Conical Heat Source

The Conical option is also a volumetric heat source where heat intensity is described as Gaussian distribution at the top surface, defined by a top radius, that varies linearly in the depth of the workpiece until it reaches a bottom radius within the prescribed depth.

-

Settings below: Power, Absorptivity (% only), re, ri, H.

Settings

For a Single Point calculation enter the Power.

The Absorptivity settings are based on the Heat Source and Calculation Type selected.

For a Single Point, Batch, or Grid Calculation Type:

- Select Calculated (the default) to use the alloy's liquid resistivity to calculate the absorptivity as a function of temperature. To adjust this calculation, enter a different prefactor than the default (

1.0) in the with prefactor field. - Choose User-defined to enter absorptivity in % where you also can enter this as a function of temperature (T) i.e.

-1.6e-7*T*T+2.5e-3*T+31.

For a Heat Source Calibration Calculation Type the absorptivity is calibrated separately for each row in the Experiment Data table. Select an option to calibrate absorptivity:

- Calculated (prefactor calibrated) (the default) to use the calculated absorptivity and calibrate the prefactor.

- Constant (calibrated) to calibrate the absolute value of absorptivity.

About the Absorptivity Model and the section Heat Source Calibration for more.

The Absorptivity settings are based on the Heat Source and Calculation Type selected.

For this heat source and with a Single Point, Batch, or Grid Calculation Type enter the absorptivity % for the selected heat source model. The default is 60 %. For Heat Source Calibration calculations there are no further settings.

This field is available:

- For a Single Point, Batch, or Grid Calculation Type and when Calculated is selected as the Absorptivity.

- For a Heat Source Calibration Calculation Type and when Calculated (prefactor calibrated is selected as the Absorptivity.

About the Absorptivity Model and the section Heat Source Calibration for more.

Enter the Wave length in nm.

The beam radius is where the power reduces to  as compared to its peak value. This is only applied on the top surface and then heat is diffused into the material based on the diffusivity of the material.

as compared to its peak value. This is only applied on the top surface and then heat is diffused into the material based on the diffusivity of the material.

For a Single Point, Batch, or Grid Calculation Type enter the Beam radius size for the Gaussian heat source model. The default is 110 μm. Hover over the field in the GUI to view the example of it as below.

For a Heat Source Calibration Calculation Type and when Calculated (prefactor calibrated is selected as the Absorptivity.

- Select Calibrated to calibrate the beam radius and the absorptivity or User-defined to enter a specific beam radius in the field (unit = μm) and only calibrate the absorptivity.

- Then choose what to Calibrate for. Select Width and depth of the melt pool, or Depth to calibrate using only the depth of the melt pool.

About the Absorptivity Model and the section Heat Source Calibration for more.

The Beam radius-Core for a Core-ring heat source is the  radius of the core beam where the power reduces to

radius of the core beam where the power reduces to  as compared to its peak value. Also see the equations in Core-ring Heat Source.

as compared to its peak value. Also see the equations in Core-ring Heat Source.

The Beam radius-Ring for a Core-ring heat source is the  radius of the ring beam. Also see the equations in Core-ring Heat Source.

radius of the ring beam. Also see the equations in Core-ring Heat Source.

The Ring radius for a Core-ring heat source is the ring radius i.e. the distance between the center of the core beam to the center of the ring beam. Also see the equations in Core-ring Heat Source.

Enter a value for the percent (%) of Amount of power in ring. This is the % of power for the ring beam. When using the Index Mode, the amount of power in the ring is set based on the selected index value (0-6).

Select a Mode:

- Custom to manually enter all parameters (the Beam radius-Core, Beam radius-Ring, Ring radius, and Amount of power in ring). See Custom Mode (Core-ring) in the theory section for more details.

- Index to select the index value (0, 1, 2, 3, 4, 5, or 6). Enter a value for Beam radius-Core and then preset values for Beam radius-Ring, Ring radius, and Amount of power in ring are based on this selection. See Index Mode (Core-ring) in the theory section for more details.

The Beam radius for a Top-hat heat source is the  radius of the top-hat beam i.e. where the power reduces to

radius of the top-hat beam i.e. where the power reduces to  as compared to its peak value. Also see the equations in detailed in Top-hat Heat Source.

as compared to its peak value. Also see the equations in detailed in Top-hat Heat Source.

The Use keyhole model checkbox is available for a Gaussian , Core-ring, or Top-hat Heat Source and when the Use separate material properties for powder checkbox is NOT selected.

Enter the Beam quality factor M2 of the laser beam.

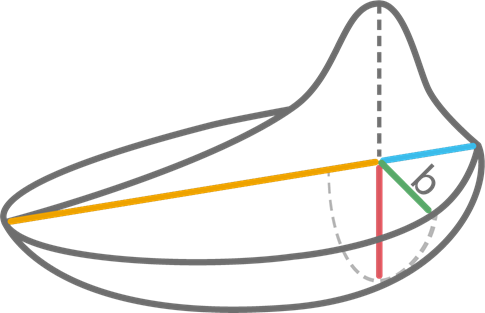

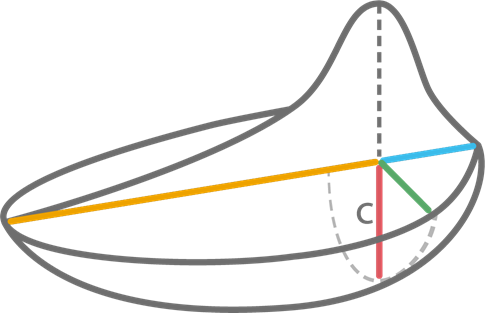

For Double ellipsoidal, also enter the following. For each field you can hover over it in the GUI to see these images that show you the location.

- ar (default is 70 μm).

- af (default is 70 μm).

- b (default is 85 μm).

- c (default is 200 μm).

For Conical, also enter the following. For each field you can hover over it in the GUI to see these images that show you the location.

- re (default is 100 μm).

- ri (default is 60 μm).

- H (default is 100 μm).