Heat Treatment of a GTD111 Alloy

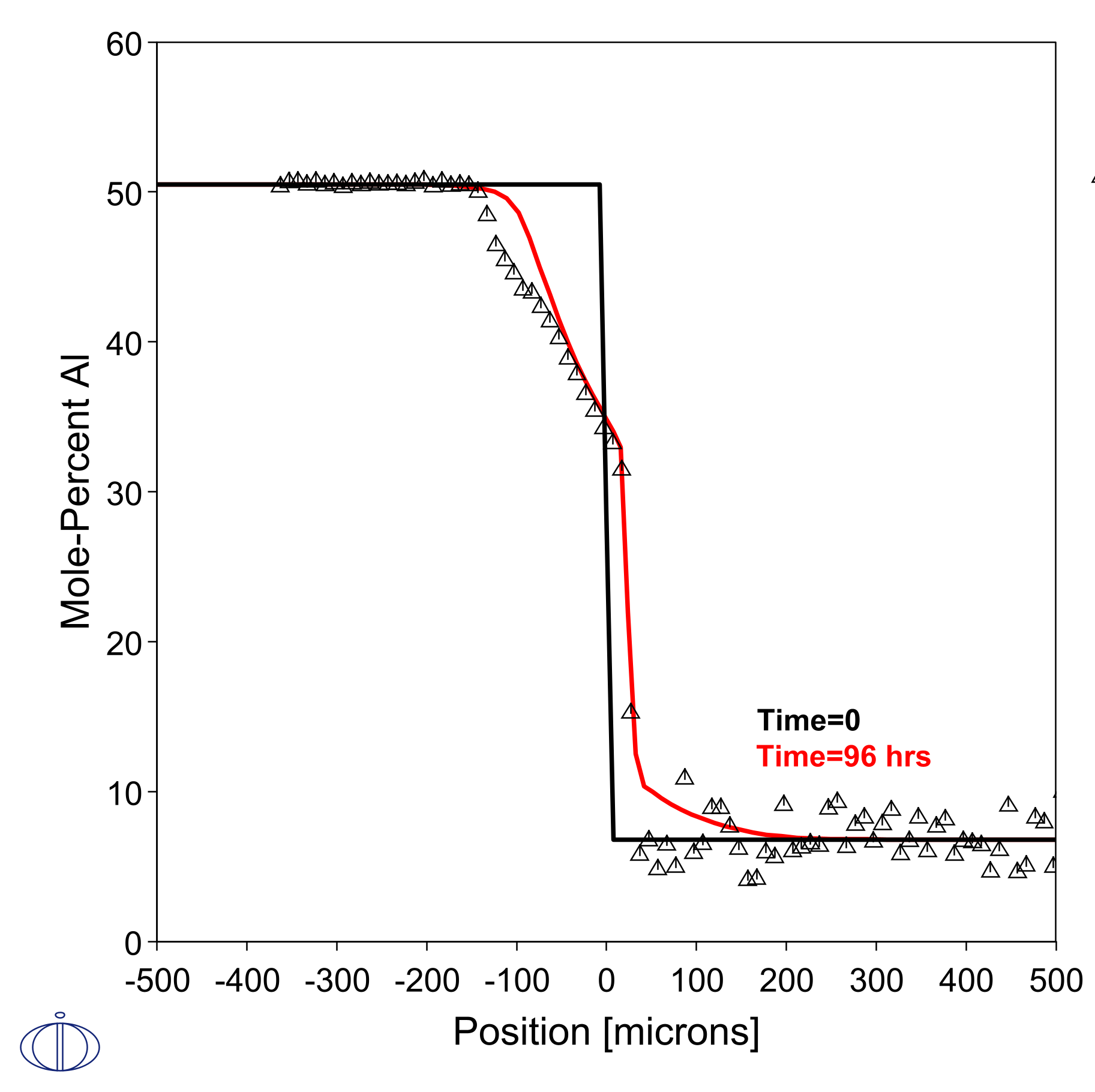

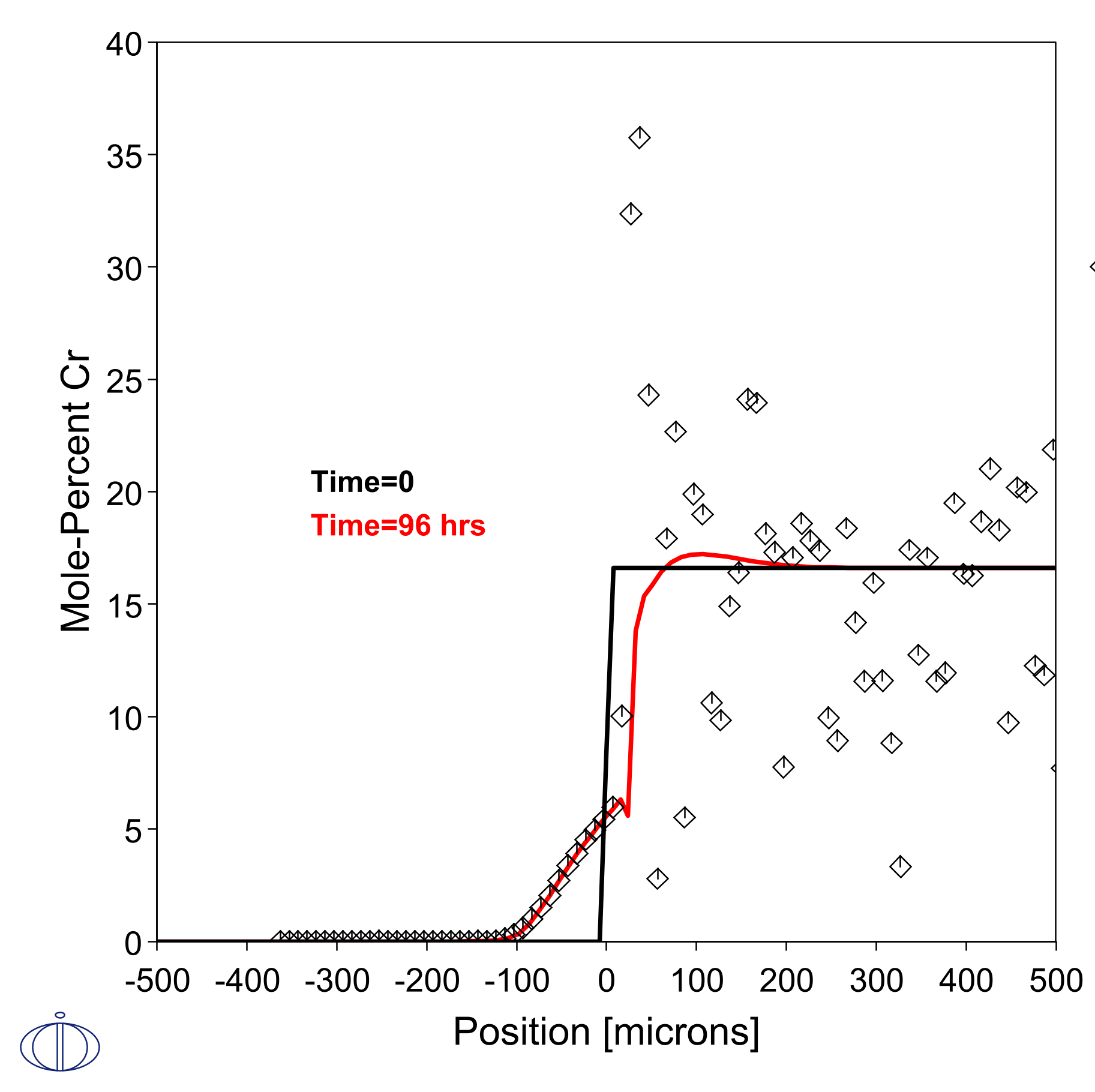

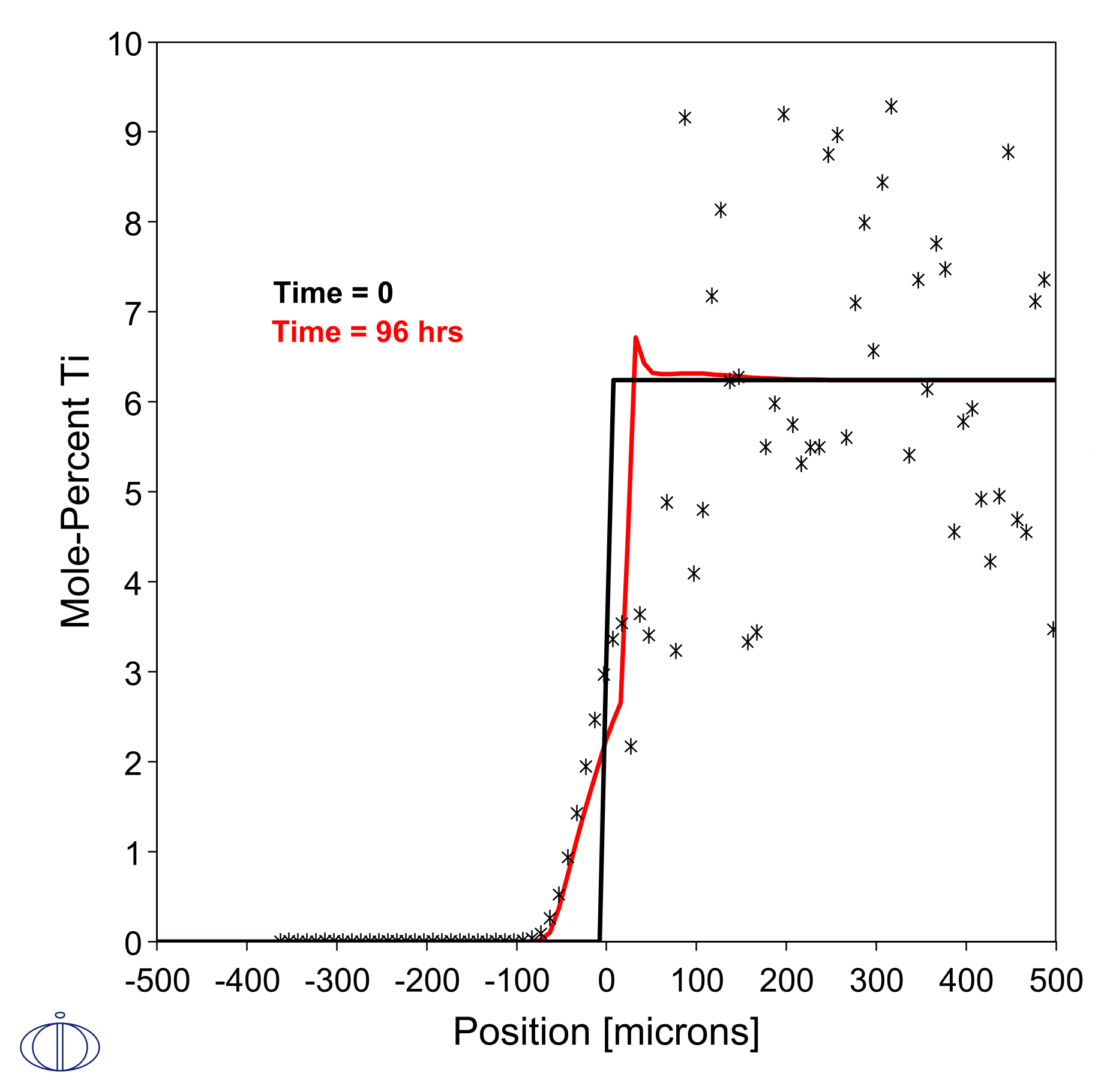

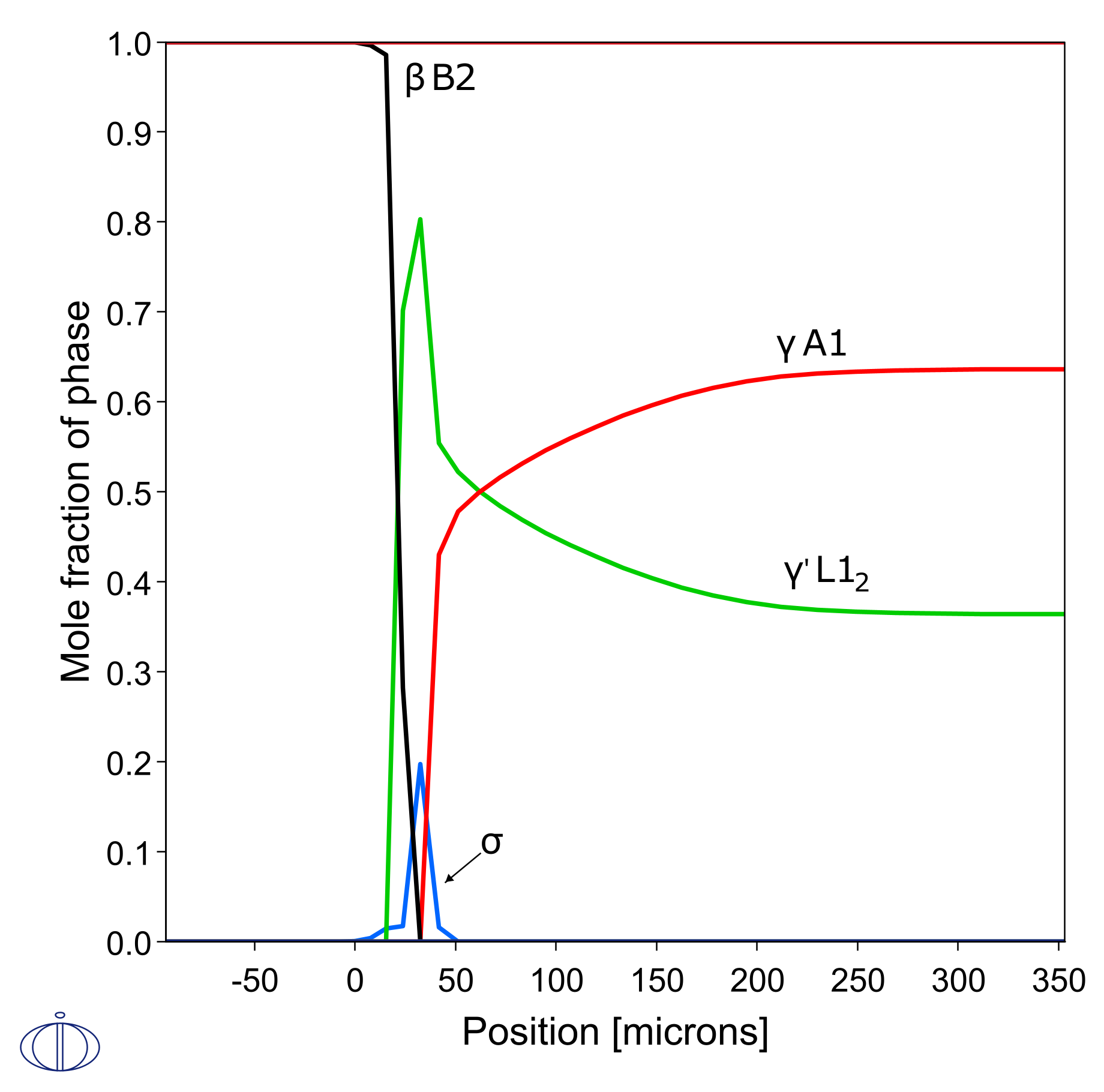

The add-on Diffusion Module (DICTRA) can be used to simulate diffusion and phase transitions in selected regions of materials during heat treatments. Below is an example using the TCS Ni-based Superalloys Database (TCNI) to simulate the heat treatment of a GTD111 alloy with an Al-Ni B2 coating for 96 hours at 1050 °C. The simulation regards a 500 nm region of coating on a 500 nm region of sample.

Read more about the Diffusion Module (DICTRA) on our website. There is also a Getting Started with the Diffusion Module (DICTRA) page available. If you are in Thermo‑Calc, press F1 to search the help to learn about the available settings included with the Add-on Module.

|

|

Figure 1: Diffusion Module (DICTRA) results from the simulation of a GTD111 alloy with B2 coating for 96 hours at 1050 °C, showing the evolution of the profile of (left) Al composition and (right) Cr composition both compared with experimental data by [2006Per].

|

|

Figure 2: Diffusion Module (DICTRA) results from the simulation of a GTD111 alloy with B2 coating for 96 hours at 1050 °C, showing (left) the evolution of the profile of Ti composition, which is compared with experimental data by [2006Per] and (right) is the present phases at the final time of simulation.

Reference

[2006Per] E. Perez, T. Patterson, Y. Sohn, Interdiffusion analysis for NiAl versus superalloys diffusion couples, J. Phase Equilibria Diffus. 27, 659–664 (2006).