Precipitation Analysis of an Au-Co Alloy

Volume fractions of the precipitated phase and TTT diagrams of heat treatment have a decisive influence on the subsequent mechanical properties of high-strength precipitation-hardened noble metal alloys.

These calculations are well represented using the Precipitation Module (TC-PRISMA) with a combination of TCS Noble Metal Alloys Database (TCNOBL) and TCS Noble Metal Alloys Mobility Database (MOBNOBL), which are used in the following examples.

Read more about the Precipitation Module (TC-PRISMA) on our website. If you are in Thermo‑Calc, press F1 to search the help to learn about the available settings included with the Add-on Module.

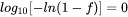

The Au-Co alloy system has been proposed as dental casting gold alloy due to its precipitation phenomenon of age-hardening process. In this example, the precipitation and TTT diagrams were simulated in the Au-1wt.%Co, from which a hcp or fcc (Co-riched) phase precipitates in the fcc-Au matrix. The criterion of determining the largest hardness in [1976Miy] is

where  is the transformed fraction of the precipitating process, ranging from 0 to 1. According to the criterion, the value of f with the largest hardness is 0.6321. The volume fractions of precipitates changing with time can then be predicted by multiplying the largest volume fraction by

is the transformed fraction of the precipitating process, ranging from 0 to 1. According to the criterion, the value of f with the largest hardness is 0.6321. The volume fractions of precipitates changing with time can then be predicted by multiplying the largest volume fraction by  . Therefore, the stop criterion of volume fraction in our simulation was chosen as the value obtained by multiplying the largest volume fractions and 0.6321. Furthermore, the mobility enhancement parameters and dislocation densities were applied due to the existence of dislocations. The parameters and the dislocation densities were derived by the apparent diffusivities of FCC_A1 Au-Co alloys. The input parameters for simulations are listed in the table, and the simulated results are shown in the plots below.

. Therefore, the stop criterion of volume fraction in our simulation was chosen as the value obtained by multiplying the largest volume fractions and 0.6321. Furthermore, the mobility enhancement parameters and dislocation densities were applied due to the existence of dislocations. The parameters and the dislocation densities were derived by the apparent diffusivities of FCC_A1 Au-Co alloys. The input parameters for simulations are listed in the table, and the simulated results are shown in the plots below.

The input parameters for simulations.

| Mobility Adjustment | Dislocation Densities | |||

|---|---|---|---|---|

| Prefactor | Q | 1wt%Co | ||

| Precipitate | FCC | 2.2 | -1414.0143 | 5.288e13/m2 |

| HCP | 18 | -1414.0143 | 5.288e13/m2 | |

Figure 1: Simulated TTT curves of the precipitated hcp and fcc phases in the Au-1wt.%Co alloy with aging time at different temperatures, compared with the experimental data from [1976Miy].

Figure 2: Volume fractions of the precipitated hcp (top labeled B) and fcc (bottom labeled C) phases in the Au-1wt.%Co alloy with aging time at different temperatures, compared with the experimental data from [1976Miy].

Reference

[1976Miy] Y. MIYAJIMA, K. YASUDA, Y. KANZAWA, Precipitation Hardening in Gold-Cobalt Alloys. Bull. Tokyo Med. Dent. Univ. 23, 41–51 (1976).

![Simulated TTT curves of the precipitated hcp and fcc phases in the Au-1wt.%Co alloy with aging time at different temperatures, compared with the experimental data from [1976Miy]. Simulated TTT curves of the precipitated hcp and fcc phases in the Au-1wt.%Co alloy with aging time at different temperatures, compared with the experimental data from [1976Miy].](../../../resources/images/tcnobl/precip_ttt-au-1wtco.png)

![Volume fractions of the precipitated hcp phases in the Au-1wt.%Co alloy with aging time at different temperatures, compared with the experimental data from [1976Miy] Volume fractions of the precipitated hcp phases in the Au-1wt.%Co alloy with aging time at different temperatures, compared with the experimental data from [1976Miy]](../../../resources/images/tcnobl/precip_volfrac_250c-au-1wtco.png)

![Volume fractions of the precipitated fcc phases in the Au-1wt.%Co alloy with aging time at different temperatures, compared with the experimental data from [1976Miy] Volume fractions of the precipitated fcc phases in the Au-1wt.%Co alloy with aging time at different temperatures, compared with the experimental data from [1976Miy]](../../../resources/images/tcnobl/precip_volfrac_300c-au-1wtco.png)