Precipitation Kinetics in FCC_A1 Al-Cu-Li-Ag Alloys

Al-Cu-Li based alloys are currently the subject of intensive research for structural applications requiring a combination of high strength, low density, high fracture toughness and good corrosion resistance, particularly relevant for aerospace applications. The mechanical properties of Al-Cu-Li alloys are controlled by the fine scale distribution of precipitate phases.

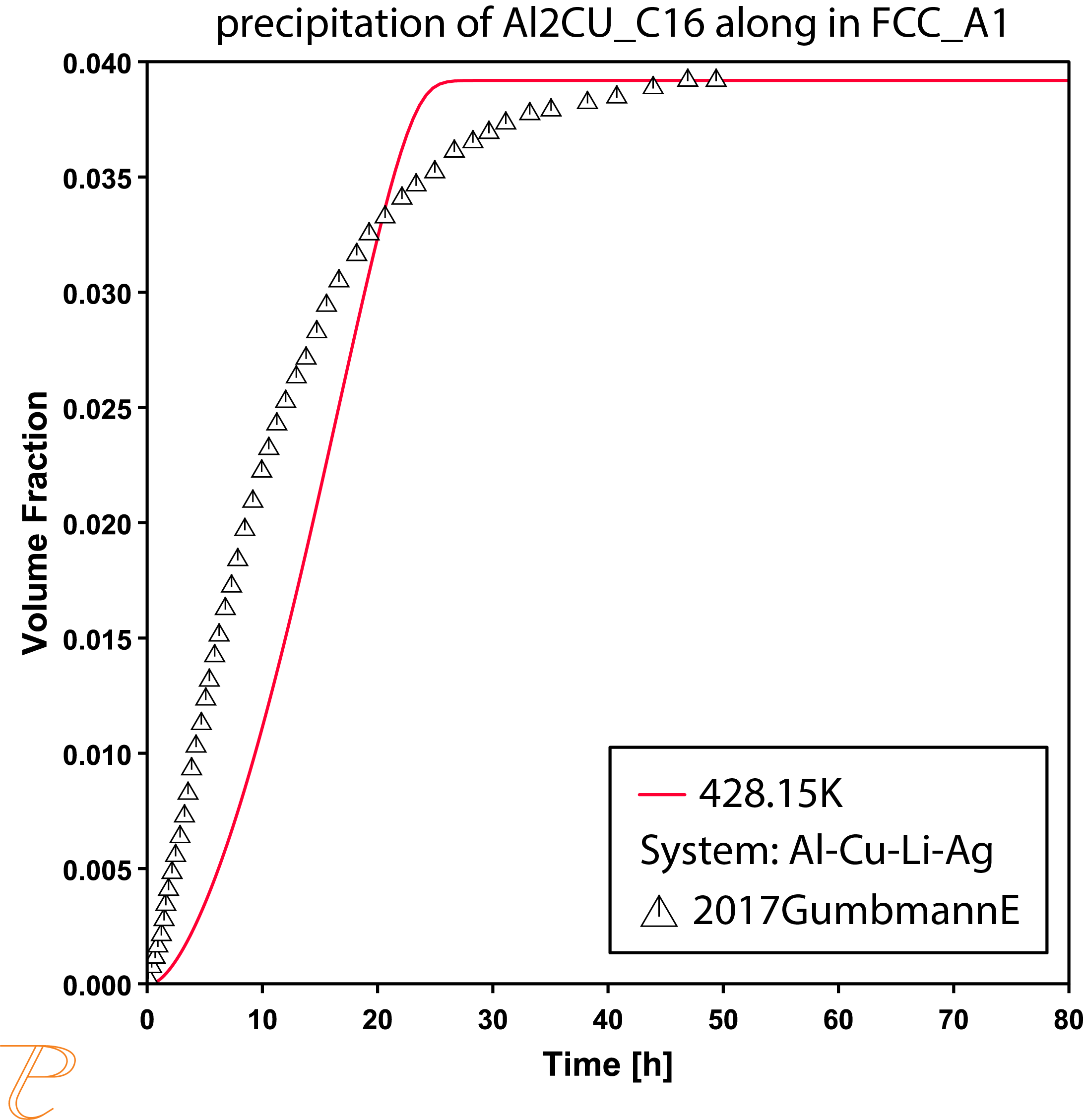

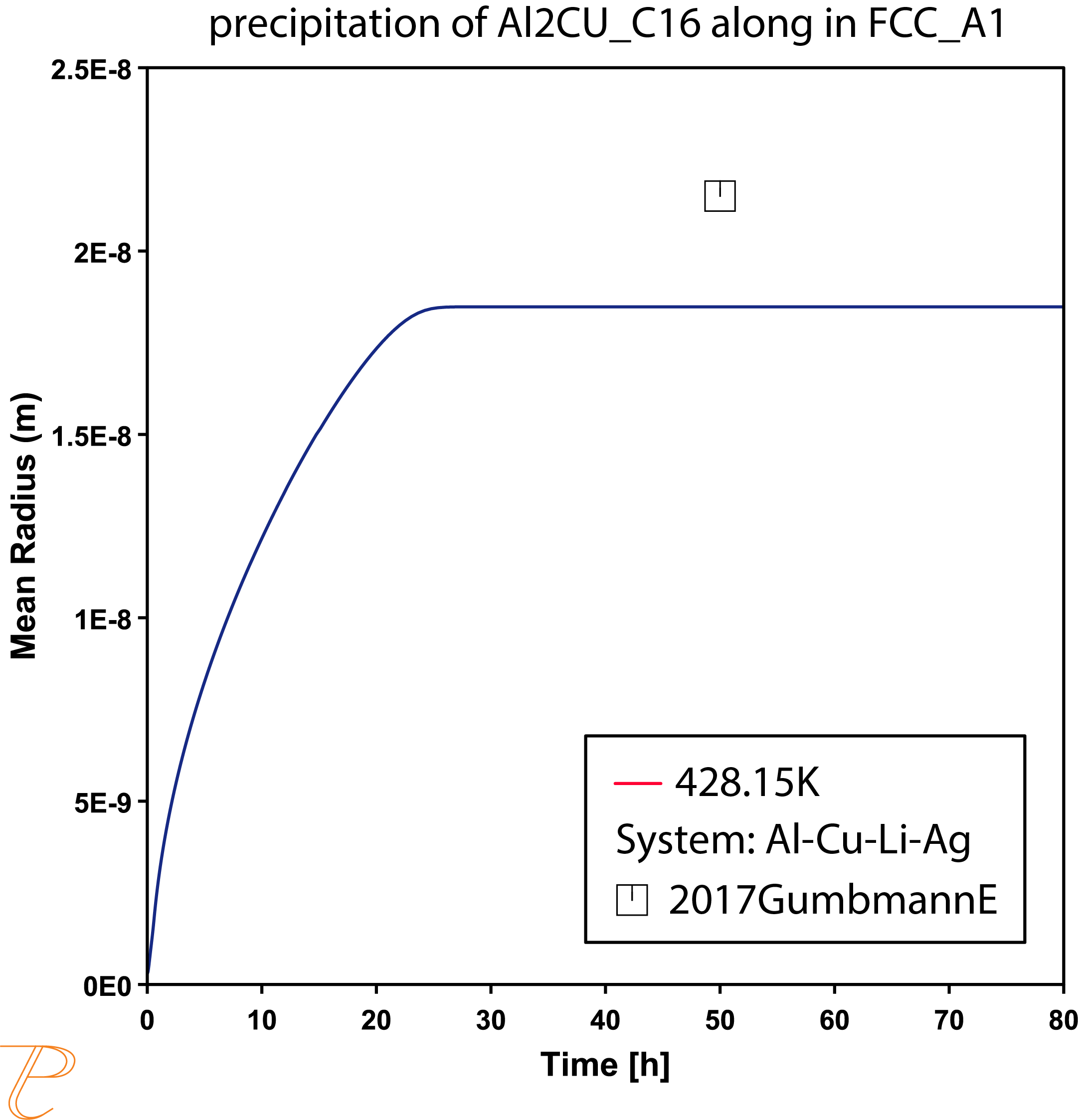

This example shows simulation results using the Add-on Precipitation Module (TC-PRISMA). It demonstrates the isothermal precipitation behavior of the AL2CU_C16 phase in FCC_A1 Al-Cu-Li-Ag alloys, using the TCS Noble Metal Alloys Database (TCNOBL) and TCS Noble Metal Alloys Mobility Database (MOBNOBL).

The simulation was carried out at an aging temperature of 428.15 K for 80 hours, and both the volume fraction and mean radius of the AL2CU_C16 phase were predicted.

Read more about the Precipitation Module (TC-PRISMA) on our website. If you are in Thermo‑Calc, press F1 to search the help to learn about the available settings included with the Add-on Module.

Figure 1: The simulated volume fractions of the precipitated AL2CU_C16 phase in FCC_A1 Al-Cu-Li-Ag alloys at an aging temperature of 428.15 K for 80 hours, compared with the experimental data reported in [2017Gum].

Figure 2: The simulated mean radius of the precipitated AL2CU_C16 phase in FCC_A1 Al-Cu-Li-Ag alloys at an aging temperature of 428.15 K for 80 hours, compared with the experimental data reported in [2017Gum].

Reference

[2017Gum] E. Gumbmann, F. De Geuser, C. Sigli, A. Deschamps, Influence of Mg, Ag and Zn minor solute additions on the precipitation kinetics and strengthening of an Al-Cu-Li alloy. Acta Mater. 133, 172–185 (2017).