Prediction of Phase Transition Temperatures

The TCS Zr-based Alloys Database (TCZR) enables extrapolations from binaries and ternaries to higher order systems. Thus, it can be used to predict the α/β phase transformation temperatures as a function of the chemical composition of typical industrial alloys. These transformations are of technological interest since it occurs during fabrication routes, welding operations, and/or accidental thermal transients i.e. in loss of coolant accidents.

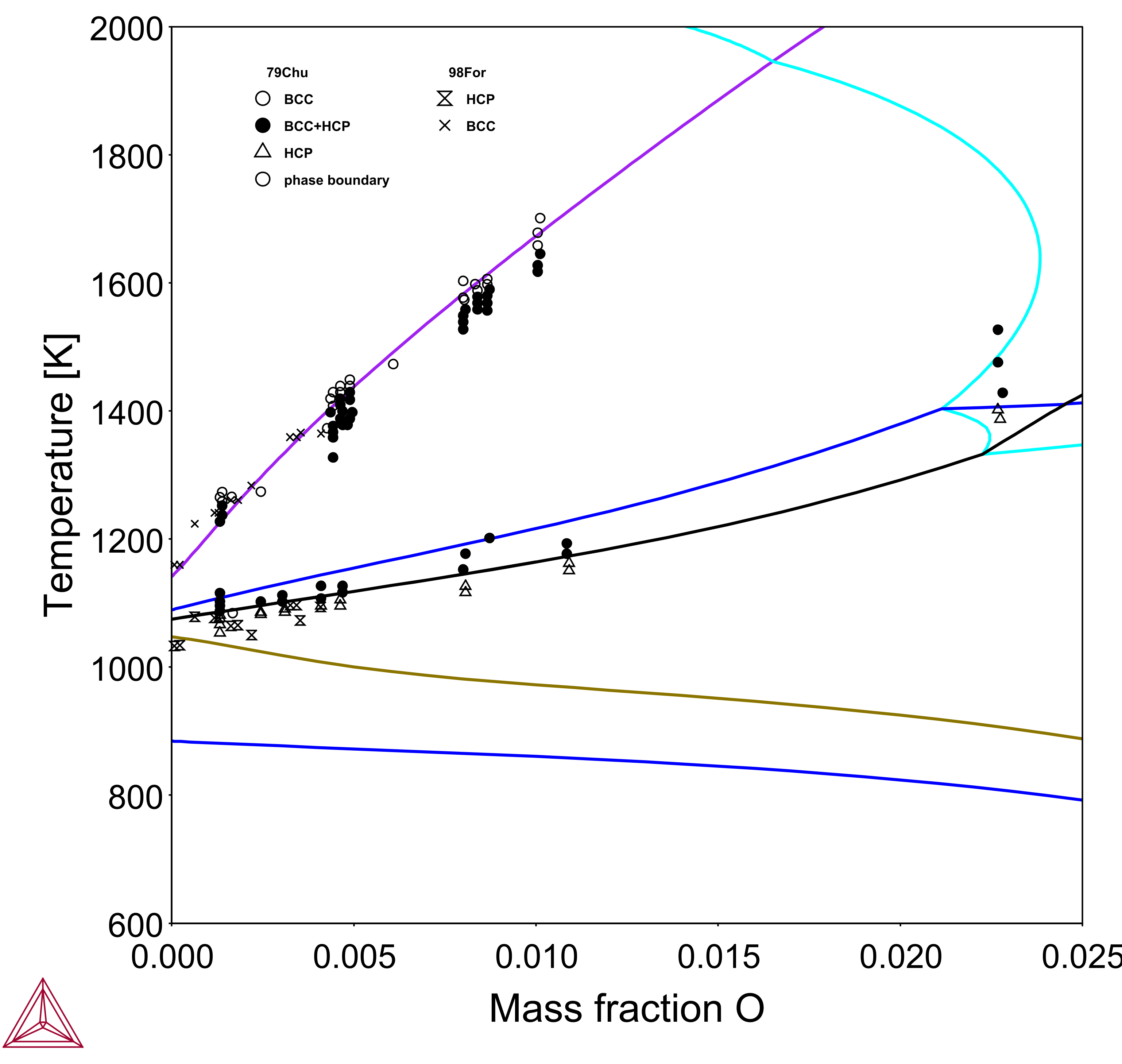

Chung [1979Chu] and Forgeron et al. [1998For] investigated the zirconium-rich portion of the pseudobinary Zircaloy 2/4-oxygen phase diagram by resistometric measurements and metallographic analysis. The BCC and HCP transition temperatures were determined and compared with calculation results where, in general, the agreement is good.

Figure 1: Calculated α/β phase boundaries of the pseudobinary Zircaloy 2/4-oxygen system with experimental data from [1979Chu] and [1998For].

The α+β → β transformation temperature is very sensitive to oxygen levels—with a 0.1 wt.% (1000 ppm) oxygen difference the temperature difference could be over 50 °C.

However, the α → α+β transformation temperature is not as sensitive. Therefore, if the oxygen level in the experimental study is unknown, the calculation results could be different as the measured transition temperatures, especially for α+β → β.

For more results about oxygen and hydrogen impact on phase equilibria and transition temperatures see these examples: Oxygen Impact on Phase Equilibria and Transition Temperatures and Hydrogen Impact on Phase Equilibria and Transition Temperatures

References

[1979Chu] H. M. Chung, T. F. Kassner, Pseudobinary zircaloy-oxygen phase diagram. J. Nucl. Mater. 84, 327–339 (1979).

[1998For] T. Forgeron, J. Brachet, F. Barcelo, A. Castaing, J. Hivroz, J. Mardon, C. Bernaudat, Experiment and Modeling of Advanced Fuel Rod Cladding Behavior Under LOCA Conditions: Alpha-Beta Phase Transformation Kinetics and EDGAR Methodology, in Zirconium in the Nuclear Industry: Twelfth International Symposium (ASTM International, PA), 1998; pp. 256-278.