About the Martensitic Steel Strength Property Model

The Martensitic Steel Strength Property Model, available with the Property Model Calculator and the Steel Model Library, is available to predict the general flow stress properties of martensitic steels, such as hardness, stress at arbitrary strain, yield strength, ultimate tensile strength, Young's modulus, etc.

To run calculations with the Steel Models requires a valid maintenance license plus licenses for both the TCFE (version 9 and newer) and MOBFE (version 4 and newer) databases. Also see our website to learn more about the Steel Model Library and other related examples.

The model evaluates the following in consecutive steps:

- Martensite fraction based on composition, annealing temperature, and quench temperature

- Hardness of the as-quenched microstructure

- Effect of tempering on microstructure and hardness

- Young's modulus based on the composition of the matrix phase and contributions from precipitates

- Strain hardening response (flow stress) based on the final hardness after tempering

The hardness is evaluated by considering the individual contributions to hardness from intrinsic hardness, solid solution hardening and martensite hardening (as-quenched and tempered). The effect of tempering temperature is described on the basis of a physical model, with an applied correction using a neural network model describing the effect of tempering time. It is possible to predict precipitates forming at the tempering temperature and their individual properties will add to the total strength of the steel.

The resulting hardness forms the foundation for evaluating the flow stress by means of estimating the strain hardening response of the steel. Deviations in predicted flow stress properties can be corrected by changing key parameters in the settings, which are:

- Pre-straining (accounts for cold work the material may have been subjected to)

- Flow stress model (Ramberg-Osgood or Voce) and model specific parameters

- Young's modulus

- Constant strength addition

Graphite, Diamond, and Gas phases are all suspended throughout the calculation.

Read about the theory in Flow Stress.

Background

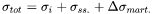

Steels undergoing austenitization, or at least partial austenitization (i.e., intercritical annealing), may form martensite upon quenching. The mechanical properties of martensite depend heavily on the content of interstitial elements in the parent austenite but are of course also affected by other elements and secondary phases. In general, a martensitic steel exhibits the following contributions to strength (or hardness):

where  is the total intrinsic hardness of the phases in the material,

is the total intrinsic hardness of the phases in the material,  is the contribution from solid solution hardening from each phase, and

is the contribution from solid solution hardening from each phase, and  is the additional hardening due to formation of martensite from the parent austenite.

is the additional hardening due to formation of martensite from the parent austenite.

The  and

and  terms are modeled in the same way as in the Yield Strength Model. See About the Yield Strength Property Model.

terms are modeled in the same way as in the Yield Strength Model. See About the Yield Strength Property Model.

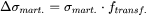

The last term (  ) in Eq. 1 can further be decomposed into:

) in Eq. 1 can further be decomposed into:

where  is the hardening effect of the formation of martensite and

is the hardening effect of the formation of martensite and  is the fraction of parent austenite that has transformed to martensite. In the Martensitic Steel Strength Property Model, the fraction transformed is evaluated using the Martensite Fractions Model.

is the fraction of parent austenite that has transformed to martensite. In the Martensitic Steel Strength Property Model, the fraction transformed is evaluated using the Martensite Fractions Model.

About the Martensite Fractions Property Model and Martensite Fractions Property Model Settings.

This means that the evaluation of the fraction of martensite is dependent on composition, austenitization temperature, quench temperature, and other parameters. These parameters are also available from within the Martensitic Steel Strength model.

Be aware of the absence of the contribution from grain size in Eq. 1. It has been shown that parent austenite grain boundaries contribute very little to the overall strength, due to the numerous other defects and interfaces that form during a martensitic transformation. The grain size may, however, affect the martensitic transformation itself in terms of the residual austenite content, which is modeled separately.

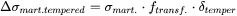

Eq. 1 is valid for the as-quenched condition, however, martensitic steels are most often tempered, which decomposes the martensite (and the residual austenite), to reduce brittleness. In the tempered condition, the martensite hardening contribution is reduced by reduction of dislocation density and precipitation of carbides. The carbides may also contribute significantly to the overall hardness and thus reduce the softening or even cause what is known as a secondary hardening peak. Eq. 2 thus becomes:

[Eq. 3]

where  is a number between 0 and 1 and depends on tempering temperature and composition. In addition to this, the first two terms of Eq. 1 now also contain contributions from any tempering carbides that form. Tempering carbides are obtained from a constrained equilibrium calculation using the parent austenite composition and tempering temperature, where during set up you can select what phases are allowed on the System Definer Configuration window. This is justified by the abundant nucleation sites (due to very high dislocation density) and the fact that the carbides that form are very small, which implies very short diffusion distances.

is a number between 0 and 1 and depends on tempering temperature and composition. In addition to this, the first two terms of Eq. 1 now also contain contributions from any tempering carbides that form. Tempering carbides are obtained from a constrained equilibrium calculation using the parent austenite composition and tempering temperature, where during set up you can select what phases are allowed on the System Definer Configuration window. This is justified by the abundant nucleation sites (due to very high dislocation density) and the fact that the carbides that form are very small, which implies very short diffusion distances.

The tempering behavior as function of time is modeled using a neural network trained on a large dataset covering mainly carbon and low-alloy steels, which provides a correction term to the total calculated hardness of the steel in the quench and tempered condition based on the physical model described above. For most of the steels considered, a very rapid decrease of hardness is expected with time, resulting in an asymptotic approach to an apparent stable value. Such a highly non-linear behavior, also exhibiting dependency on composition, lends itself well to machine learning (ML) based models.

The use of the predicted hardness to further predict flow stress is detailed in the theory for Flow Stress. Since the framework for evaluating flow stress is generally applicable, it is described as a separate section.

FCC_A1, BCC_A2, and Cementite must be selected on the System Definer Configuration window but can be suspended with settings available on the Property Model Configuration window. If these phases are excluded on the System Definer, the calculation does not work.

The Model only accepts phases that have had the intrinsic strength assessed. For a list of available phases see the section in the theory for Yield Strength Property Model regarding the Intrinsic Strength model.

The input parameters are entered on the Configuration window for the Property Model Calculator. There are also settings on the Plot Renderer where you can choose from the available and relevant axis variables.

For an example see PM_Fe_10: Martensitic Steel Strength.

[2008Pav] E. J. Pavlina, C. J. Van Tyne, Correlation of Yield Strength and Tensile Strength with Hardness for Steels. J. Mater. Eng. Perform. 17, 888–893 (2008).