TC‑Python Process Metallurgy Examples

You can find several learning resources on the Process Metallurgy page of our website (or in Thermo‑Calc, go to Help → Thermo‑Calc website). You can also subscribe to the Thermo‑Calc newsletter to be kept up-to-date about upcoming releases, training, examples, videos and much more.

To use the Process Metallurgy Module with TC-Python requires a full license to Thermo‑Calc 2022b or newer, a valid MS&S subscription, a license to the TCS Metal Oxide Solutions Database (TCOX8 or newer), plus a license to TC-Python.

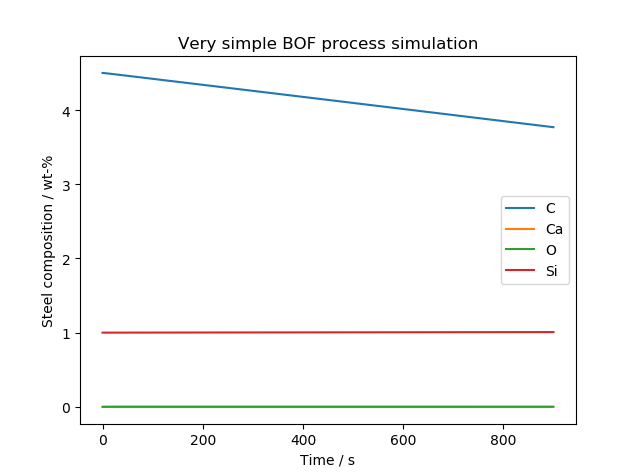

This example shows how to create a basic adiabatic equilibrium calculation for a process metallurgical problem. The equilibrium between a steel and slag melt and oxygen is calculated.

File name: pyex_PMET_01_Single_adiabatic_equilibrium.py and the OXDEMO database is used.

This example has some text output for the calculation result:

Stable phases: {'GAS#1', 'IONIC_LIQ#2', 'IONIC_LIQ#1', 'HATRURITE#1'}

Temperature: 1758.4 °C Slag phases: {'IONIC_LIQ#2', 'HATRURITE#1'}

Composition of the overall slag:

Al2O3 = 9.41 mol-%

C = 0.42 mol-%

CaO = 70.43 mol-%

Fe2O3 = 0.00 mol-%

FeO = 0.01 mol-%

SiO2 = 19.73 mol-%

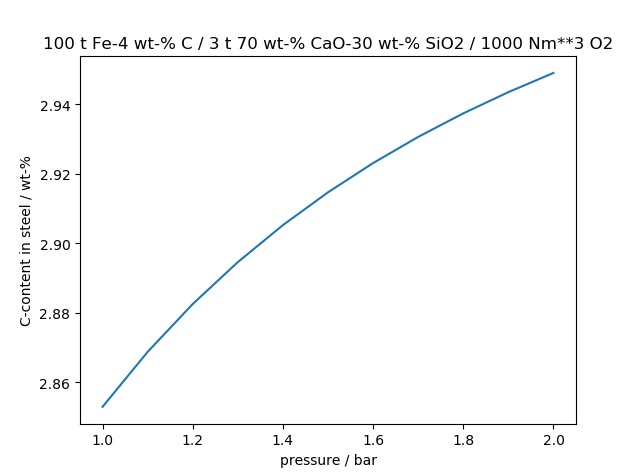

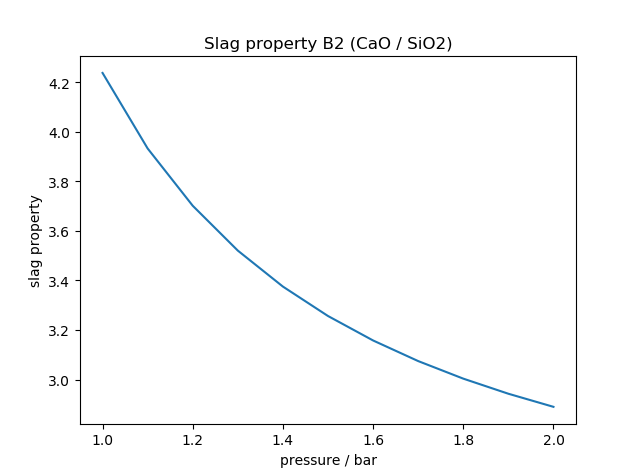

This example shows how to create adiabatic equilibrium calculations for varied pressure. The equilibrium between a steel and slag melt and oxygen is calculated.

File name: pyex_PMET_02_Stepping_adiabatic_equilibrium.py and the OXDEMO database is used.

The equilibrium carbon content in the steel melt in dependency of the pressure equilibrium between a steel and slag melt and oxygen for a single calculation.

The slag property B2 (CaO/SiO) in dependency of the pressure.

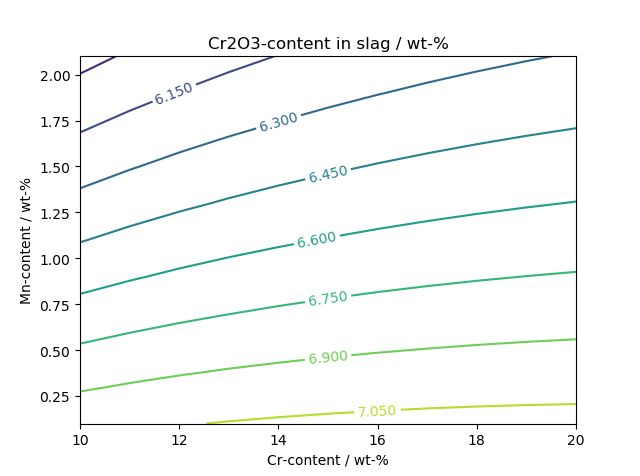

This example shows how to create isothermal equilibrium calculations with varied composition of two steel components.

File name: pyex_PMET_03_Mapping_isothermal_equilibrium.py.

To run this example requires TCOX9 and higher.

The equilibrium content of Cr2O3 in the slag in dependency of the Cr and Mn content in the steel.

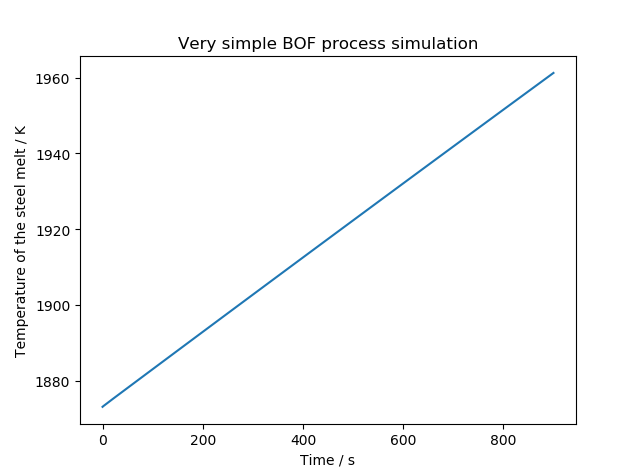

This is example shows how a Vacuum Oxygen Decarburization (VOD) refining process could be modeled. It is inspired by the work of Ding et al. [2000Din] and the validation data is derived from the paper.

File name: pyex_PMET_05_VOD_process_simulation.py

To run this example requires TCOX9 and higher. Slight model adjustments might be required based on the version.

This example is based on the Graphical Mode example, PMET_07: Vacuum Oxygen Decarburization Kinetics, which is also an application example showcased on our website.

This model shows several features of process simulations, such as:

- time-dependent mass transfer coefficients

- time-dependent pressure

- inclusion flotation

- cooling due to heat losses

- heat transfer between the zones

- control of degassing

This example takes several minutes to calculate. The results are updated continually. The plot examples shown are the final iterations.

For this specific example, several plots are generated. There are slight differences compared to the application example on the website. For general background theory and an overview of how the example is set up and to interpret the results, it is recommended to read the PDF, also available on the website.

[2000Din] R. Ding, B. Blanpain, P. T. Jones, P. Wollants, Modeling of the vacuum oxygen decarburization refining process. Metall. Mater. Trans. B. 31, 197–206 (2000).