Material to Material Calculator Conditions Tab Settings

Conditions and axis variables for the Material to Material Calculator are set in the Conditions tab on the Configuration window. The conditions to set depend on the type of calculation.

For an example, see T_14: Fe-Cr-Ni Transition Comparison Using the Material to Material Calculator.

The Material to Material template (on the  My Projects Configuration window under Equilibrium) creates a project to perform calculations to examine how materials transition from one into the other. The project consists of a System Definer, Material to Material Calculator, and a Plot Renderer.

My Projects Configuration window under Equilibrium) creates a project to perform calculations to examine how materials transition from one into the other. The project consists of a System Definer, Material to Material Calculator, and a Plot Renderer.

Functions: This is the same as the Equilibrium Calculator. See Equilibrium Calculator: Calculating and Plotting Functions

Options: This is the same as the Equilibrium Calculator. See Equilibrium Calculator: Options Tab Settings

Settings

The following outlines what you can set on the Conditions tab.

Select the Composition unit: Mass percent, Mole percent, Mass fraction, or Mole fraction.

Under Condition Definitions:

- For both the First material and Second material, define the values (and units) of the state variables Temperature and Pressure.

- Enter a Fraction of second material.

- For a Single equilibrium calculation this is used as condition for the calculation.

- For a One Axis calculation this is used as the start value for the calculation.

- For a One Axis or Phase diagram calculation, and if the Fraction of second material is chosen as the Axis Definition>Quantity, then it is stepping between the Min and Max.

- For both materials, select the Dependent component.

- Select the Activity conditions checkbox to define the Activity of component for one or more components. By default this is not selected. Click the

Add quantity and

Add quantity and  Remove quantity buttons to add and remove conditions.

Remove quantity buttons to add and remove conditions. - The reference state is defined on the System Definer.

For each First material and Second material component there are individual settings to define as follows.

Enter a unique Material name for each. This name is used on the plots and in the quantity definitions so it is good to use as concise a name as possible that clearly identifies each material. For example, Martensitic Steel for the First material and Alloy 800 for the Second material.

For each Composition field, enter numeric values for each material.

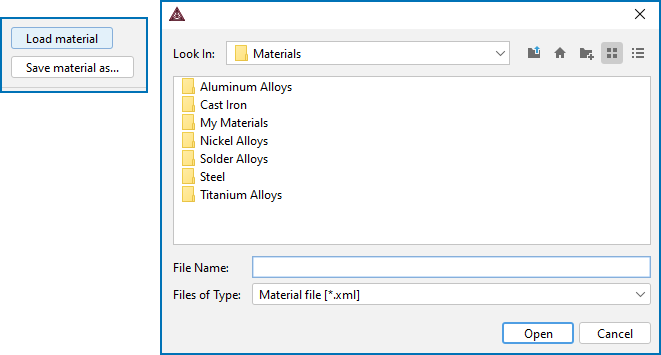

- Click Save material as after defining a composition to add it for reuse in other projects and calculations.

- Click Load material to add the composition of a predefined material from an xml file. Also see How To Load or Save a Material

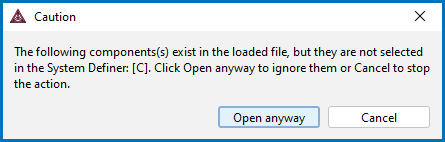

If the user-defined material file includes one or more components not defined on the System Definer, then you are prompted to make a decision:

Click Open anyway to continue to load the material file even with the undefined component(s). However, this means the undefined component is excluded at first from calculations until it is further defined on the System Definer. Once the material is defined then it is automatically included the next time calculations are run. Otherwise, click Cancel to stop the action and either edit the material file or manually define the component(s) in the System Definer.

How To Load or Save a Material

Click Load material to open a material file. The default folder opens to the Materials folder included with your installation.

About the Material Files and Installed Examples, Manuals, and Materials Folders

You can click Save material as to save the material you defined, for example Ferritic. Add your own folders as needed.

Global Settings: System Definer

For the System Definer, and if you load a material file and then change the composition, a message displays The composition has changed. This means that the original values/composition do not match the values you are using for the project. The message is cleared by either reloading the material file or editing the composition field to the original value.

Click to select a Calculation Type:

- Single equilibrium (no axes): To calculate a single point. The results from this calculation are displayed in the Visualizations window if a Table Renderer is used.

- One Axis: To vary a quantity on the X-axis; the fraction of one of the materials or temperature.

- Phase diagram: To calculate a section in a multicomponent system between two materials, transitioning from one into the other. The phase diagram is mapped within a specific space that is constructed by the two mapping axis-variables; the fraction of one of the materials and temperature.

- One Axis: Define the axis variable using these fields and menus: Quantity, Min, Max, Step division, Type, and Step Method.

- Phase diagram: Define the two axis variables using these fields and menus: Quantity, Min, Max, Step division, and Type.

Also see additional setting details for Step division, Type, and Step Method.

If the Calculator already has a Plot Renderer as a successor and you change the stepping/mapping quantities, then the quantities represented on the X- and Y-axis are automatically updated in the Plot Renderer.

Enter a Step division and select a Type: Linear - min no. of steps, Linear - max step size, or Logarithmic - scale factor.

- For Linear - min no. of steps, the Step division value specifies a minimum number of steps that is calculated between the minimum and maximum value during the stepping/mapping operation.

- For Linear - max step size, the Step division sets the maximum size of each step. For Logarithmic - scale factor, Step division specifies the scale factor of a logarithmic function that distributes the steps from the initial equilibrium to the minimum and maximum values defined.

From the Step Method list, choose Normal or Separate phases.

- Normal allows a stepping calculation with the chosen independently-varying equilibrium condition (axis-variable).

- Separate phases calculates how the Gibbs energy for a number of phases varies for different compositions. This is particularly useful to calculate Gibbs energies for complex phases with miscibility gaps and for an ordered phase that is never disordered (e.g. SIGMA-phase, G-phase, MU-phase, etc.).