T_14: Fe-Cr-Ni Transition Comparison Using the Material to Material Calculator

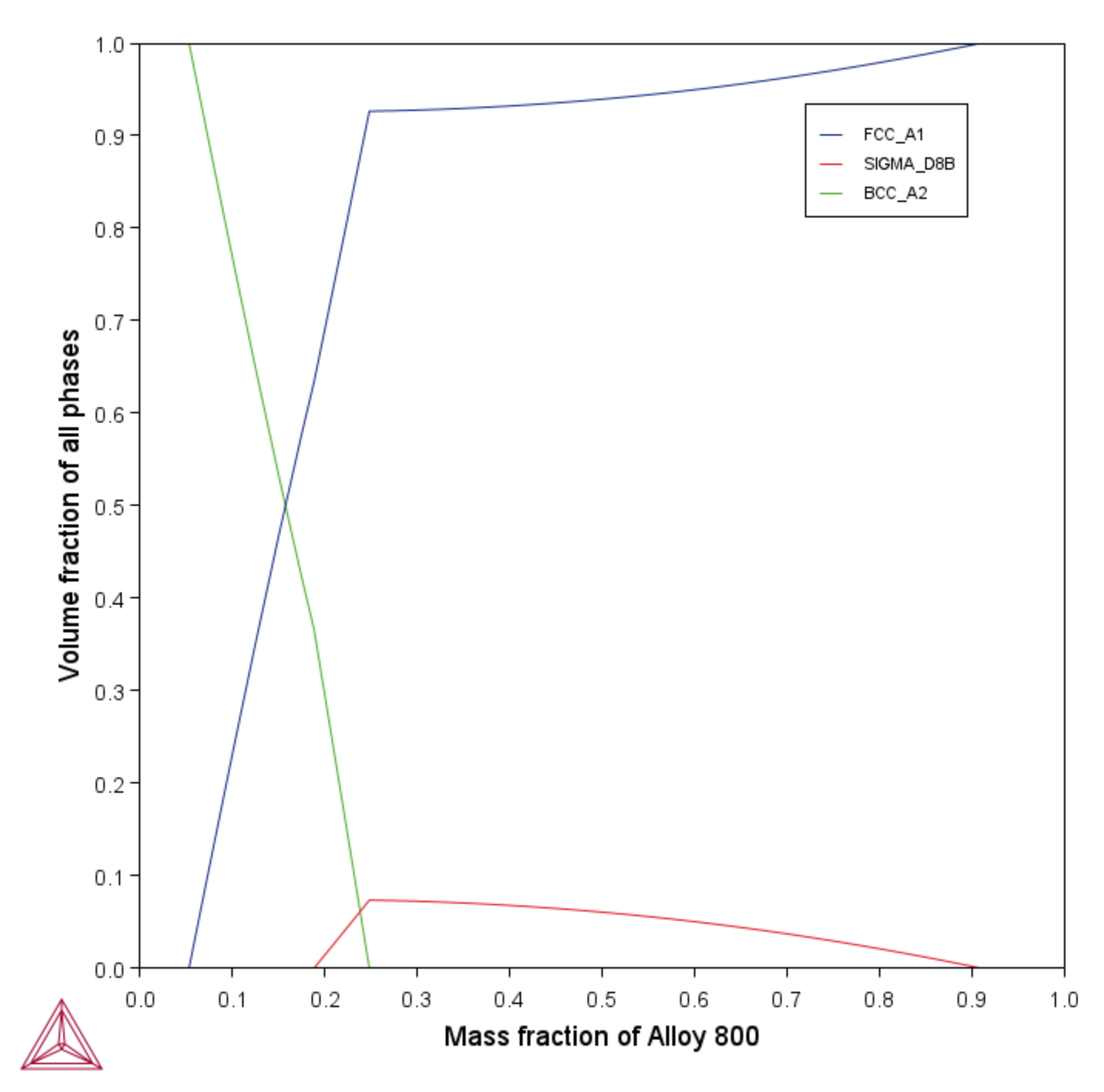

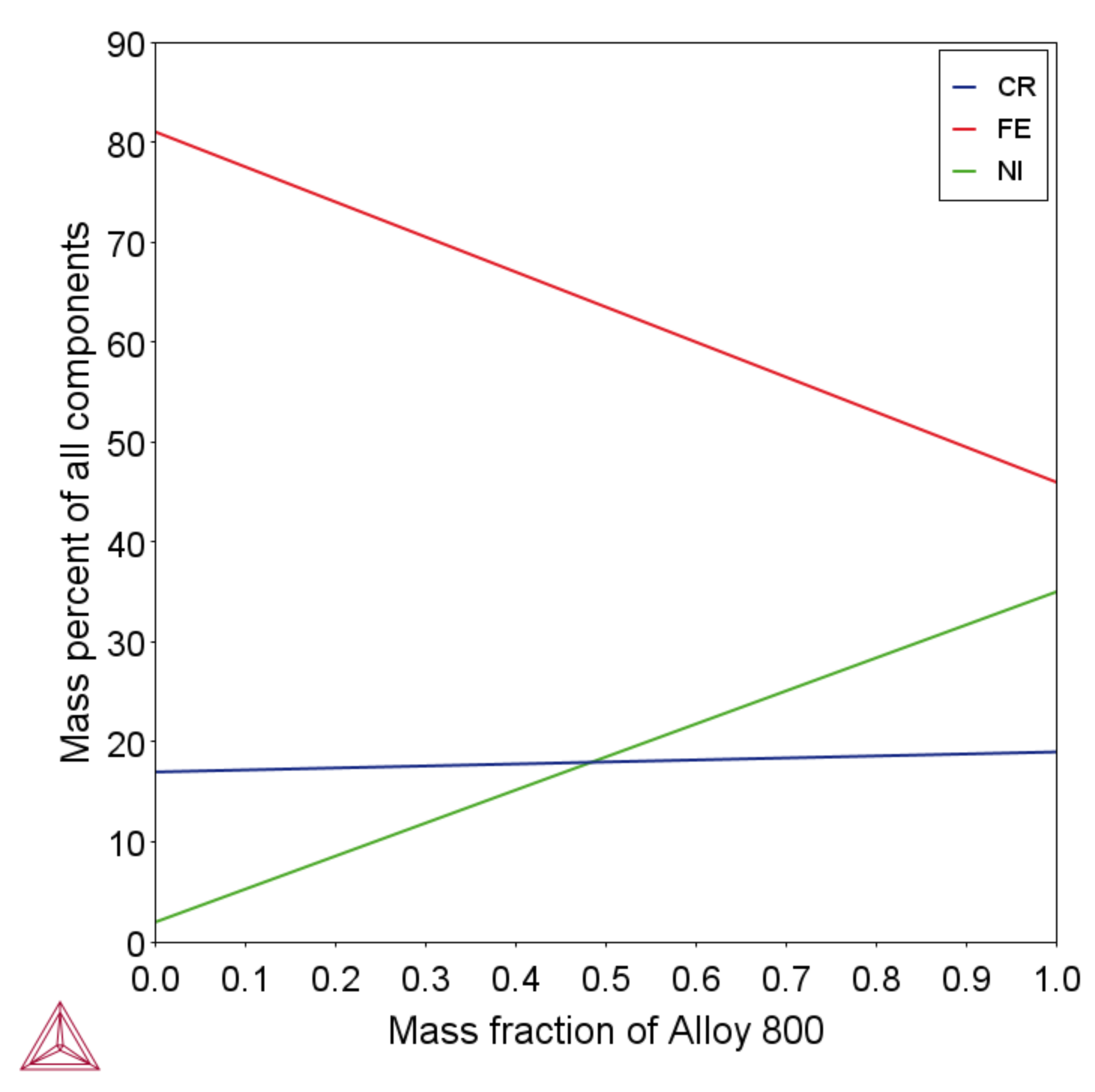

In Graphical Mode, you use the Material to Material Calculator to perform calculations and examine how two materials transition from one into the other. The calculations in this example search for potential deleterious phases during heat treatment of alloys joined together. In this example, the calculation steps between a model martensitic stainless steel (Fe-17Cr-2Ni) and a model Alloy 800 composition (Fe-35Ni-19Cr). Neither alloy is predicted to form the deleterious sigma phase at 600 °C. However sigma is predicted to form at a wide range of mixtures of these two materials, which could have an impact on mechanical properties if it forms.

The example, as defined when you open it, uses a One Axis calculation (also known as a property diagram), a temperature of 650 °C, to compare the volume fraction of all phases to the mass fraction of Alloy 800. The Fraction of the second material (Alloy 800) is set to 50% (0.5), which for a One Axis calculation is used as the start value.

As with all the examples, you can adjust the settings to plot a variety of combinations of output to see how the Material to Material Calculator works before defining your own project.

The plot for this calculation compares the volume fraction of all phases of Material 1 (martensitic stainless steel) to the mass fraction of Material 2 (Alloy 800). In the plots you can see where each phase (FCC_A1, SIGMA_D8B, and BCC_A2) evolves. As you step from Material 1 to Material 2, the FCC_A1 phase starts forming at about 5% (0.05), SIGMA-D8B phase starts to evolve at about 19% (0.19), and the BCC_A2 transitions from Material 1 to Material 2 where it stops forming at approximately 24% (0.24). The purpose of the calculation is to determine at what fraction of Alloy 800 the deleterious sigma phase forms and this is shown for these compositions.

- Folder: Thermo‑Calc

- File name: T_14_Fe-Cr-Ni_Material_to_Material.tcu

Visualizations

This example is included as a tutorial on our website and as part of the Graphical Mode Examples playlist on our YouTube channel.

Open the example project file to review the node setup on the Project window and the associated settings on the Configuration window for each node. For some types of projects, you can also adjust settings on the Plot Renderer Configuration window to preview results before performing the simulation. Click Perform Tree to generate plots and tables to see the results on the Visualizations window.

In the Plot Renderer settings window, click Show more and Show less to toggle between viewing all or some of the available settings.

The default plot shows the volume fraction of all phases as a function of the mass fraction of the second material, which in this case, is Alloy 800. You can see that the martensitic stainless composition is BCC at this temperature, and the highly alloyed stainless is FCC. Neither material is expected to form any deleterious phase on its own at 650 °C.

However, mixtures of these two materials, which could arise from a graded transition joint, weld, or potentially a diffusion couple, show some stability for the deleterious sigma phase at this temperature. You can try to make small adjustments to the initial chemistry to reduce the potential for sigma phase to form.

Figure 1: This plot shows the volume fraction of phases when changing composition from the Martensitic Steel (First material) to the Alloy 800 (Second material). This calculation uses the Material to Material Calculator to examine the transition of phases for two compositions of Fe-Cr-Ni. The purpose is to determine at what fraction of Alloy 800 does the deleterious sigma phase start to form. See the text for details.