Liquidus and Solidus Temperatures

The TCS Mg-based Alloys Database (TCMG) can be used to predict the liquidus and solidus temperatures, as well as incipient melting temperatures, which are critical to design heat treatments and melting processes.

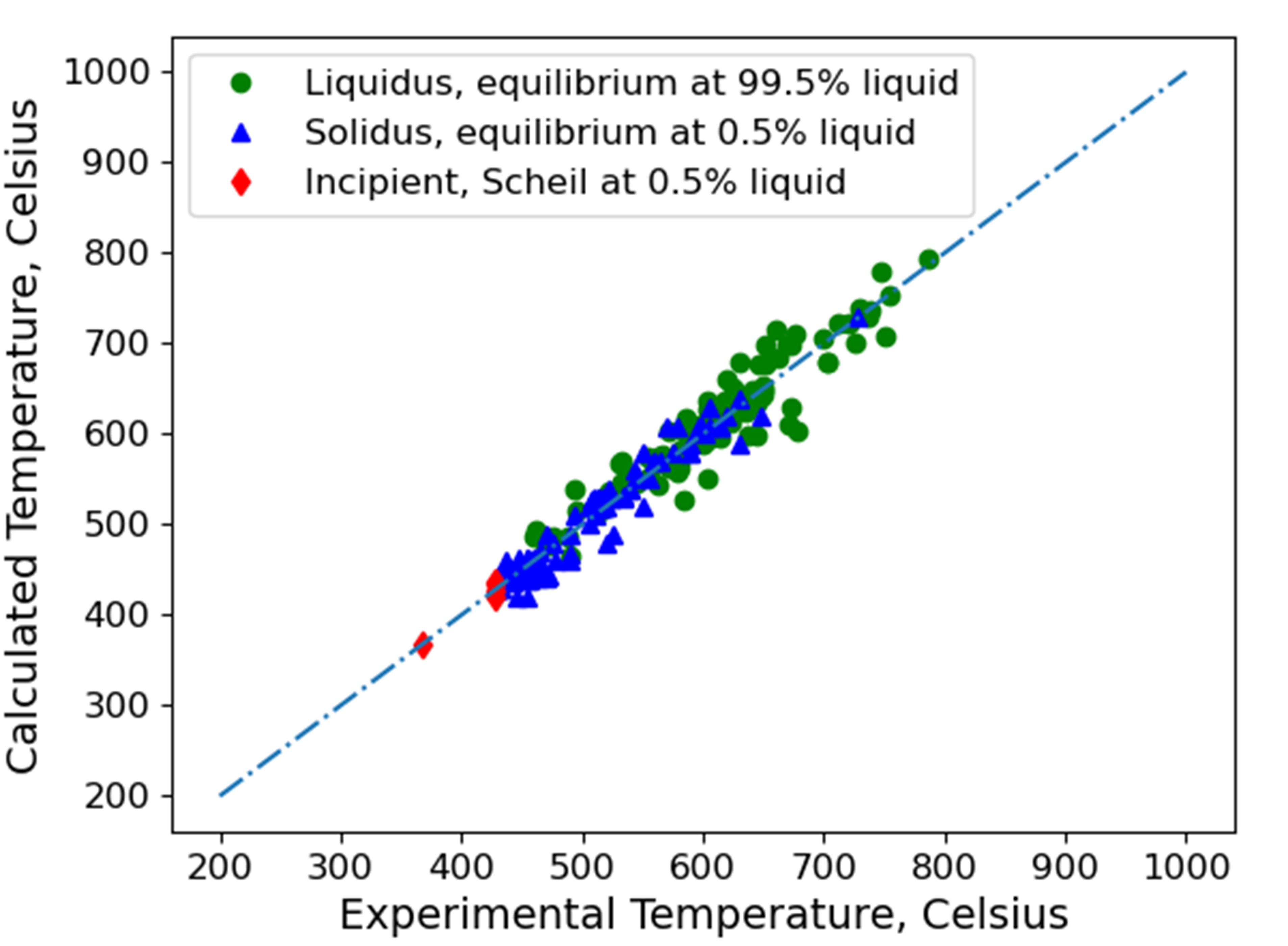

This example plot compares calculated and measured liquidus temperatures and solidus temperatures, as well as incipient temperatures, from about 200 magnesium alloys. These are mostly customized alloys from the literature and include about 30 industrial alloys.

It should be noted that when such a temperature was determined with thermal analysis, the thermal effect must be large enough to be detected. Because of this, as-measured liquidus temperatures often do not accord with the start precipitation of the very first solid phase, if its amount is negligible. As-measured solidus temperatures could be before the alloys had fully solidified. In order to account for such uncertainties in experiments, the temperature at 99.5 % liquid is used as calculated liquidus temperature and that at 0.5% liquid as calculated solidus temperature. Calculated incipient temperatures are taken from Scheil simulations (at 0.5 % liquid) in order to account for the non-equilibrium feature.

Figure 1: Comparison of calculated vs experimental liquidus temperatures and solidus temperatures, as well as incipient melting temperatures, for Mg alloys.

Read more about Scheil Solidification Simulations on our website, including how to select the right model for your simulation. If you are in Thermo‑Calc, press F1 to search the help to learn about using Scheil.