Applications Using the Diffusion Module (DICTRA)

These examples use the thermodynamic TCS Ti/TiAl-based Alloys Database (TCTI) and its compatible TCS Ti-alloys Mobility Database (MOBTI) with the Add-on Diffusion Module (DICTRA).

Read more about the Diffusion Module (DICTRA) on our website. There is also a Getting Started with the Diffusion Module (DICTRA) page available. If you are in Thermo‑Calc, press F1 to search the help to learn about the available settings included with the Add-on Module.

Diffusion Kinetics Simulation in BCC_A2 Ti-alloys for Biomedical Implants

BCC_A2 Ti-alloys are attractive for several biomedical applications due to their biologically safe character, good biocompatible, low Young’s modulus, and high mechanical strength. The elements Nb and Zr are two important components in the BCC_A2 biomedical Ti-alloys with a low Young’s modulus. However, surgeons always require the implant biomaterials with a high Young’s modulus to suppress springback during surgery. The addition of element Cr can help develop novel BCC_A2 Ti-alloys with a changeable Young’s modulus.

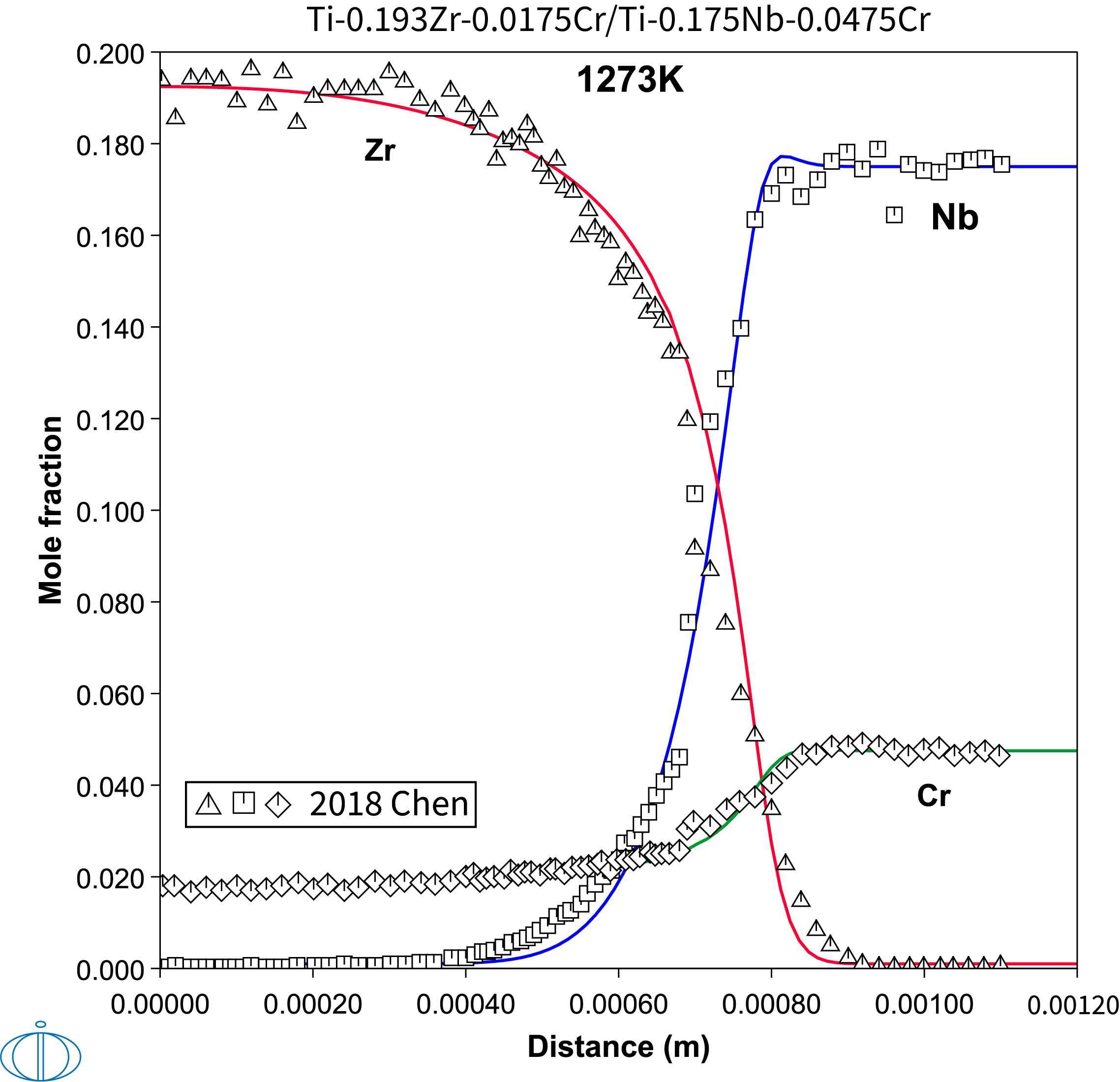

The following example shows the results from the Diffusion Module (DICTRA) simulation of a BCC_A2 Ti-0.193Zr-0.0175Cr/Ti-0.175Nb-0.0475Cr diffusion couple using the latest versions of the databases (TCTI6 and MOBTI5). The concentration profiles within the diffusion couple are simulated, with an annealing temperature 1273 K for 90000 s.

Figure 1: The simulated concentration profiles within the BCC_A2 Ti-0.193Zr-0.0175Cr/Ti-0.175Nb-0.0475Cr diffusion couple using DICTRA, with an annealing temperature 1273 K for 90000 s, and compared with the experimental data [2018Che].

Diffusivity Calculations in Ti3Al for High Temperature Applications

The formation of Ti3Al in Ti-alloys achieves a combination of properties that make them suitable for demanding applications in high temperature and high stress environments. These properties include improved high temperature strength, oxidation resistance, increased creep resistance, enhanced structural stability, and balanced mechanical properties. The development of such intermetallic compounds as structural materials inevitably requires knowledge of relevant diffusion data. Attention to such investigations is attractive not only for accumulating experimental data but also for gaining a deeper insight into the underlying microscopic diffusion mechanisms.

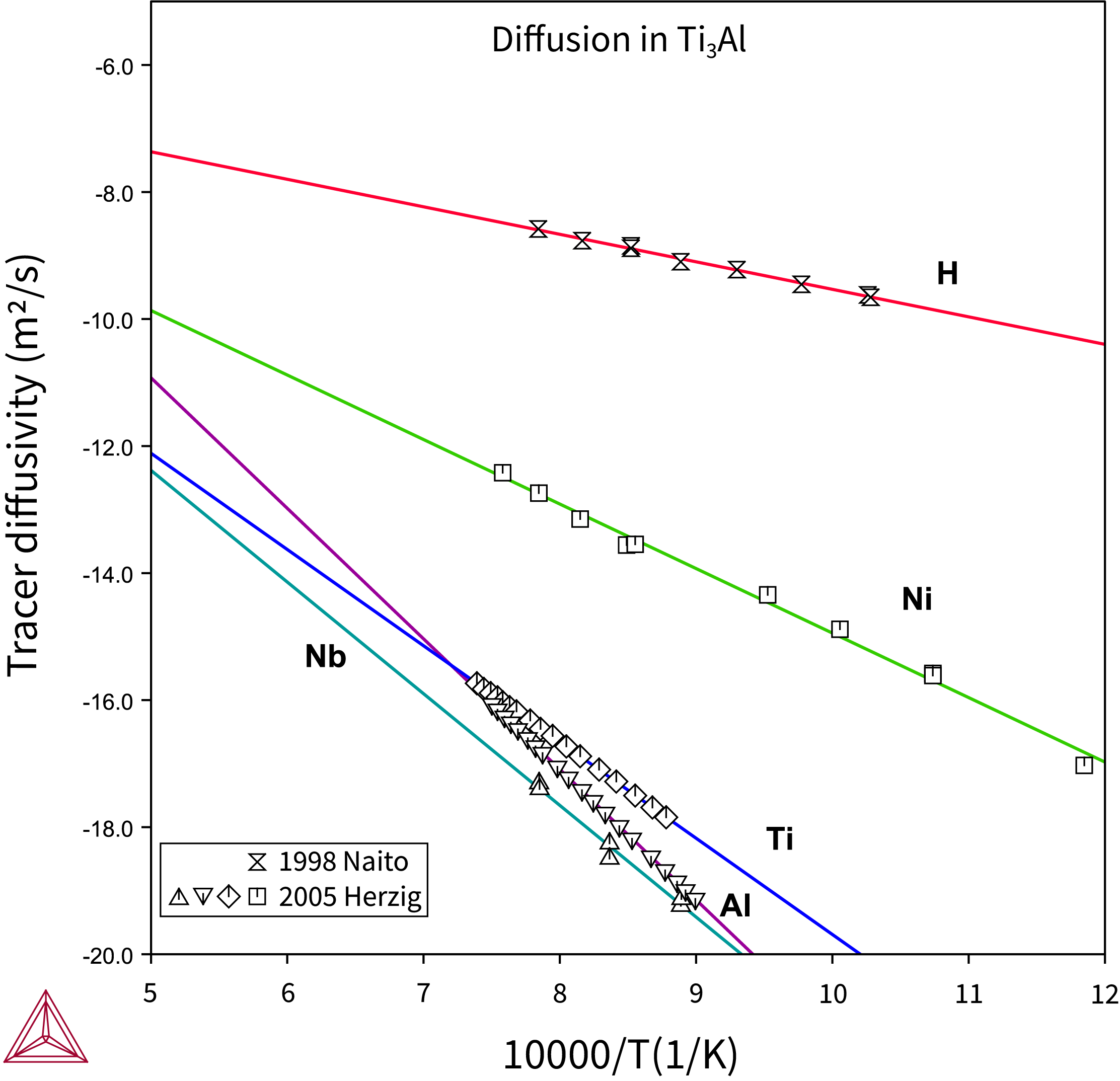

The following example shows the results from the simulation of tracer diffusivities of the substitutional elements Ni, Ti, Al, and Nb, as well as the interstitial element, H, in the compound Ti3Al as a function of temperature.

Figure 2: The simulated tracer diffusivities of substitutional elements Ni, Ti, Al, and Nb, as well as the interstitial element H, in the compound Ti3Al as a function of temperature, and compared with the experimental data [1998Nai; 2005Her] .

References

[1998Nai] S. Naito, M. Yamamoto, M. Doi, M. Kimura, High‐Temperature Diffusion of Hydrogen and Deuterium in Titanium and Ti3Al. J. Electrochem. Soc. 145, 2471–2475 (1998).

[2005Her] C. Herzig, S. Divinski, Bulk and Grain Boundary Diffusion in Intermetallic Compounds, in Diffusion Processes in Advanced Technological Materials (Elsevier/William Andrew Publishing, 2005), pp. 173–238.

[2018Che] W. Chen, W. Li, Y. Du, Investigations on diffusion behaviors in Ti–rich Ti–Nb–Zr–Cr system: Experimental measurement and CALPHAD modeling. Calphad. 62, 223–231 (2018).