Homogenization / Solution / Aging Treatments: PA Alloy

Solution treatment is to dissolve (fully or partly) particles that form at the grain boundaries into the (Al) matrix. Homogenization is to eliminate or reduce the composition segregation in the (Al) matrix. Very often these kinds of treatments can be performed at the same time and thus are not distinguished. Temperature and time are the most important parameters that need to be optimized for a heat treatment.

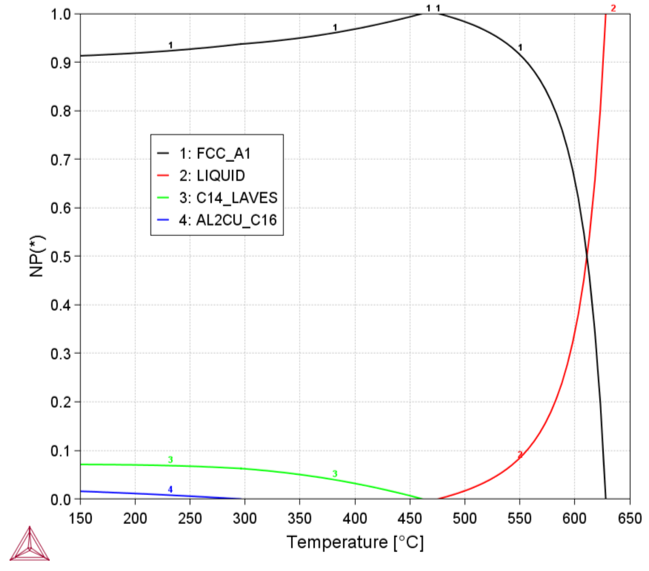

For a solution treatment, the heating temperature can be preliminarily determined according to an equilibrium stepping shown below. A narrow window of 462-475 °C of single (Al) phase was predicted for alloy PA Alloy: Al-10.3Zn-1.6Cu-2Mg, wt. %. In such cases, the temperature may be determined as the mean value independently of the heating time. This agrees well with the experimental temperature of 470 °C by Marlaud [2010Mar].

Figure 1: Solution treatment showing a narrow window of 462-475 °C of single (Al) phase which was predicted for the PA Alloy (Al-10.3Zn-1.6Cu-2Mg, wt. %).

Uncertainty Calculation with the Property Model Calculator

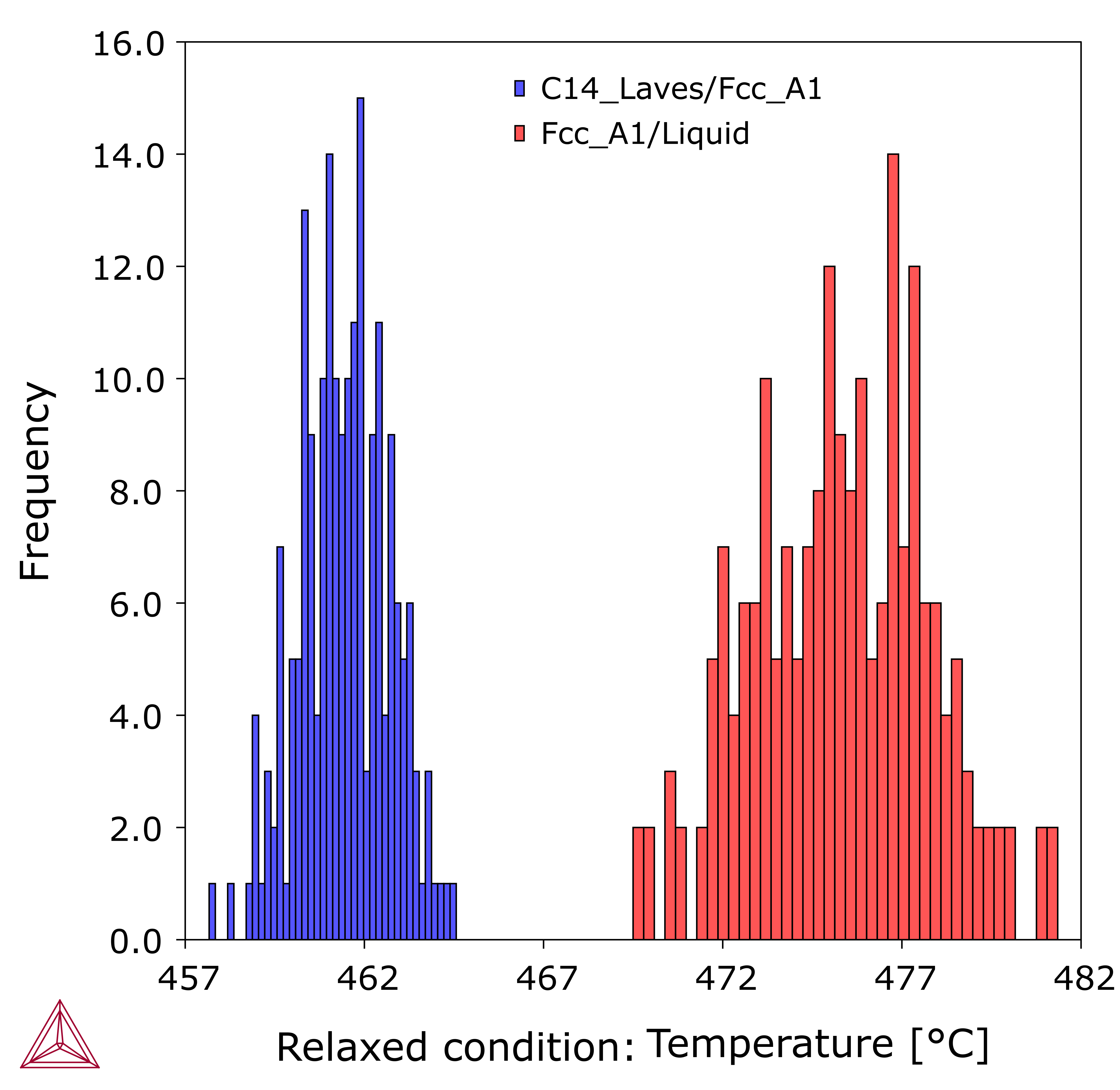

The alloy may deviate from its nominal composition. It is useful to investigate how the composition uncertainty affects the temperature window of the single-(Al)-phase region. With the Property Model Calculator in Thermo-Calc Graphical Mode you can easily take into account such uncertainties in calculations. A three percent (3 %) tolerance level was assumed for the contents of the major alloying elements, i.e. Zn 10.3±0.3, Cu 1.6±0.05 and Mg2.0±0.06, wt.%.

A sample of 200 compositions is done within the ranges according to a Gaussian distribution and calculated transition temperatures for C14_Laves / FCC_A1 and FCC_A1 / Liquid. Figure 2 plots the frequency of each obtained temperature. A single (Al) phase can be attained for all the sampled compositions, while the window is further narrowed down. The heating temperature of 470 °C is good in most cases but a bit too high at several compositions.

Read more on our website about Property Models, including information about the material specific Model Libraries (i.e steel, nickel, titanium, etc.), as well as how to create your own custom models in TC‑Python. If you are in Thermo‑Calc, press F1 to search the help.

Figure 2: Uncertainty calculations for the PA Alloy using the Property Model Calculator. Temperatures are calculated at 200 compositions and the frequency of each obtained temperature is plotted.

Aging Treatment with the Precipitation Module (TC-PRISMA)

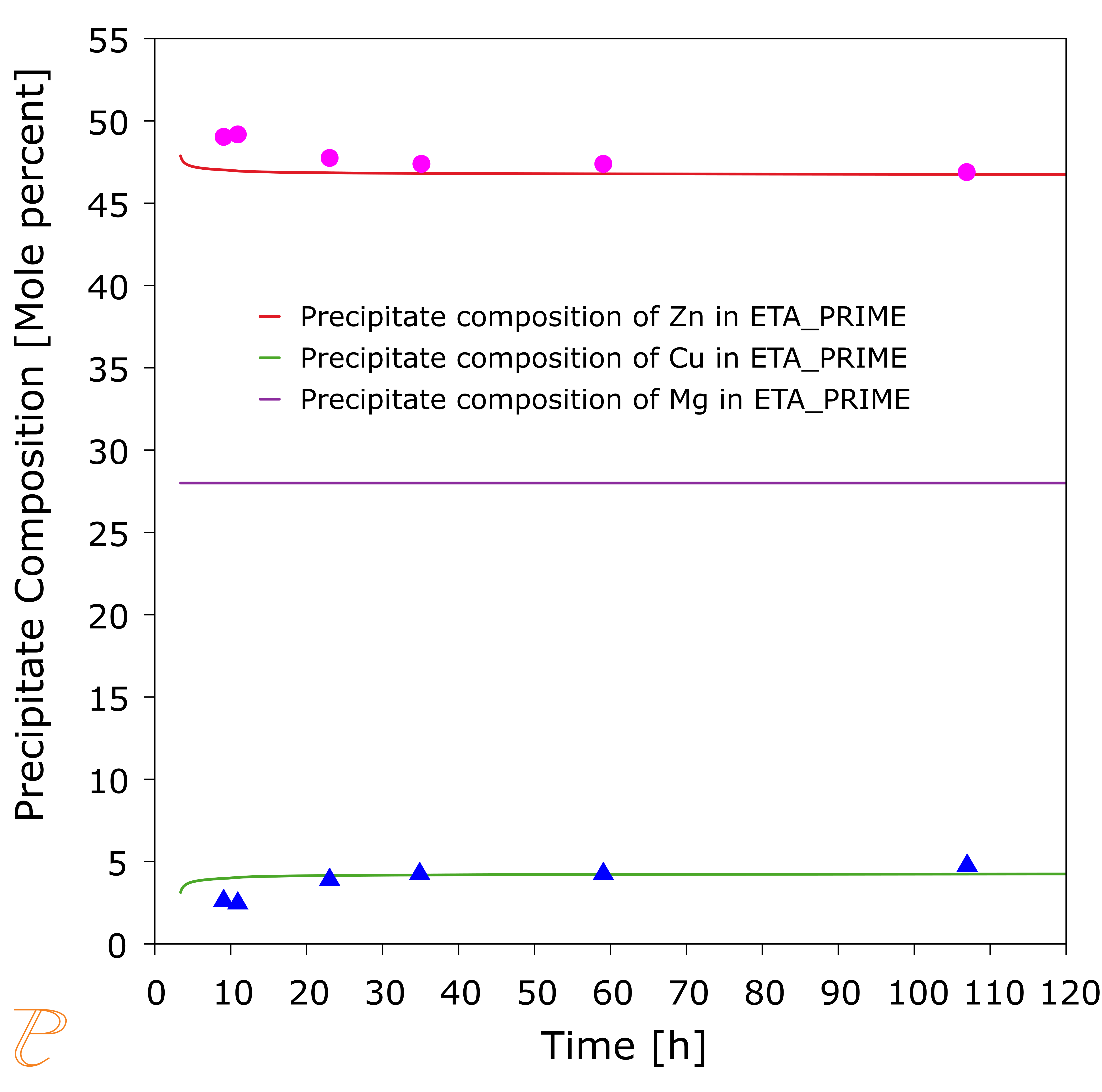

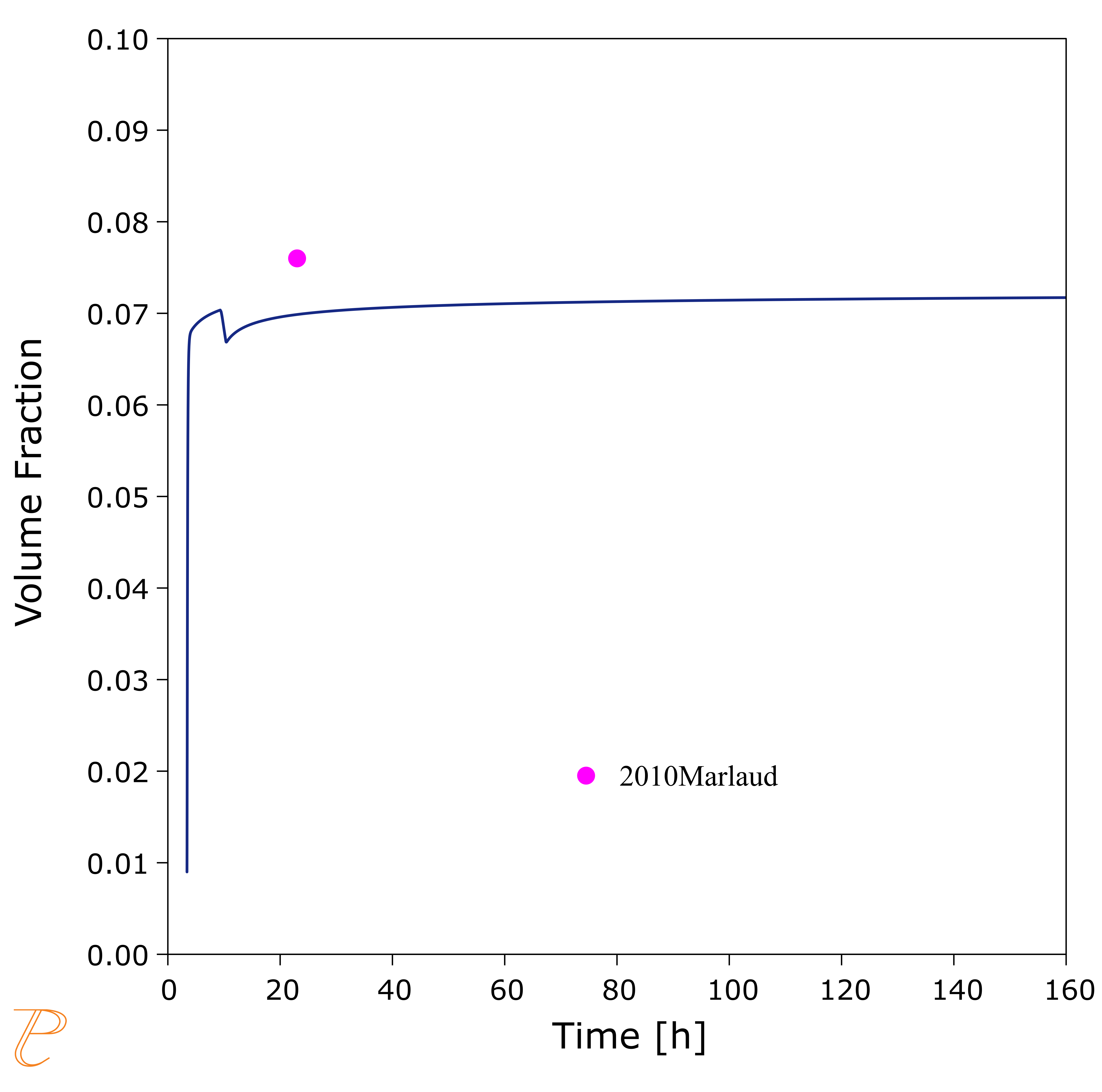

η' is a major strengthening precipitate in the 7000 series of alloys. After being quenched from the homogenization, the PA Alloy was aged (heating procedure: from 20 °C to 120 °C at 30 °C/h, 120 °C for 6 h, from 120 °C to 135 °C at 15 °C/h, and 135 °C for 96 h) by Marlaud [2010Mar]. Figure 3 and Figure 4 are from a precipitation simulation during the aging treatment. They show, respectively, the simulated solute contents in the η' precipitates and the simulated volume fraction of these precipitates.

The estimation of interfacial energy plays a central role in such a simulation. The value is estimated to be 0.045 J/m2 based on a systematic consideration of all the experimental data from this alloy [2010Mar]. If considering only the simulated aging treatment, a slightly higher interfacial energy could be used and would slightly better reproduce the experimental data, but consistency is also important. There is still room for a user to refine the interfacial energy.

Read more about the Precipitation Module (TC-PRISMA) on our website. If you are in Thermo‑Calc, press F1 to search the help to learn about the available settings included with the Add-on Module.

Figure 3: A simulation of the precipitation during the aging treatment showing the contents of the solutes in the η' precipitates for the PA Alloy. Curves are from the Precipitation Module (TC-PRISMA) simulations and symbols are experimental data.

Figure 4: The simulated volume fraction of the η' precipitates in the PA Alloy during the aging treatment. Curves are from the Precipitation Module (TC-PRISMA) simulations and symbols are experimental data.

Reference

[2010Mar] T. Marlaud, A. Deschamps, F. Bley, W. Lefebvre, B. Baroux, Influence of alloy composition and heat treatment on precipitate composition in Al-Zn-Mg-Cu alloys, Acta Mater. 58 248-260 (2010).