Solidification: Hot Tearing Susceptibility

It is found that hot tearing susceptibility of aluminum alloys can be reasonably predicted via evaluating the terminal freezing range (TFR). In general, the wider the TFR is, the more the alloy is susceptible to hot tearing.

Read more about Scheil Solidification Simulations on our website, including how to select the right model for your simulation. If you are in Thermo‑Calc, press F1 to search the help to learn about using Scheil.

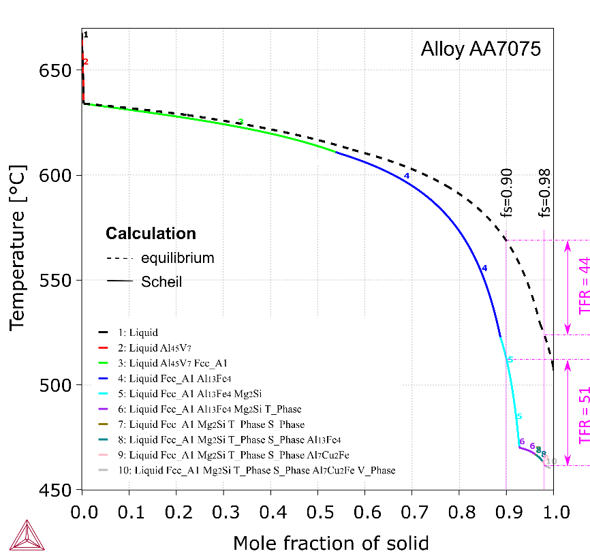

AA7075

Figure 1: AA7075 alloy has a large TFR (44-51) and is prone to hot tearing.

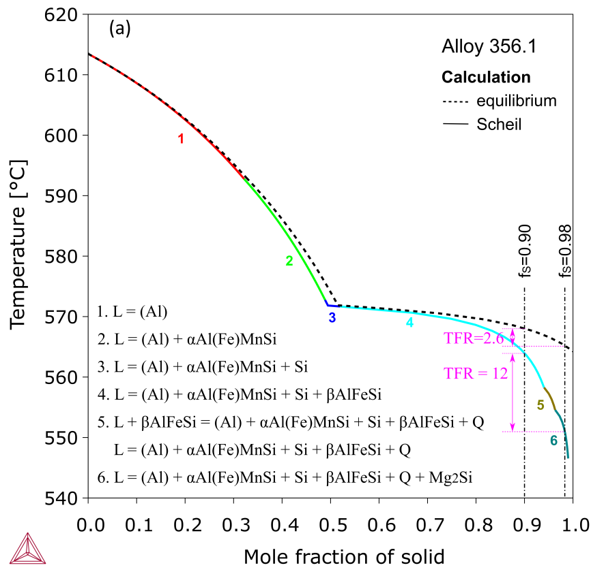

A356.1

Figure 2: A356.1 alloy has a much lower TFR (2.6-12) and is much less susceptible to hot tearing. Equilibrium calculation shows an even lower value of TFR (2.6) than the Scheil simulation. This may indicate that the risk of hot tearing may be reduced by changing experimental conditions, e.g. lowering the cooling rate or using preheated casting molds.

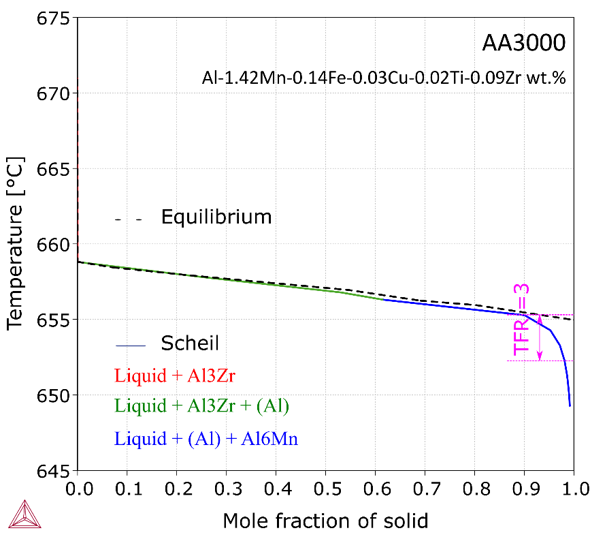

AA3000

Figure 3: AA3000 alloy has an even lower TFR and has been reported to be insusceptible to hot tearing.

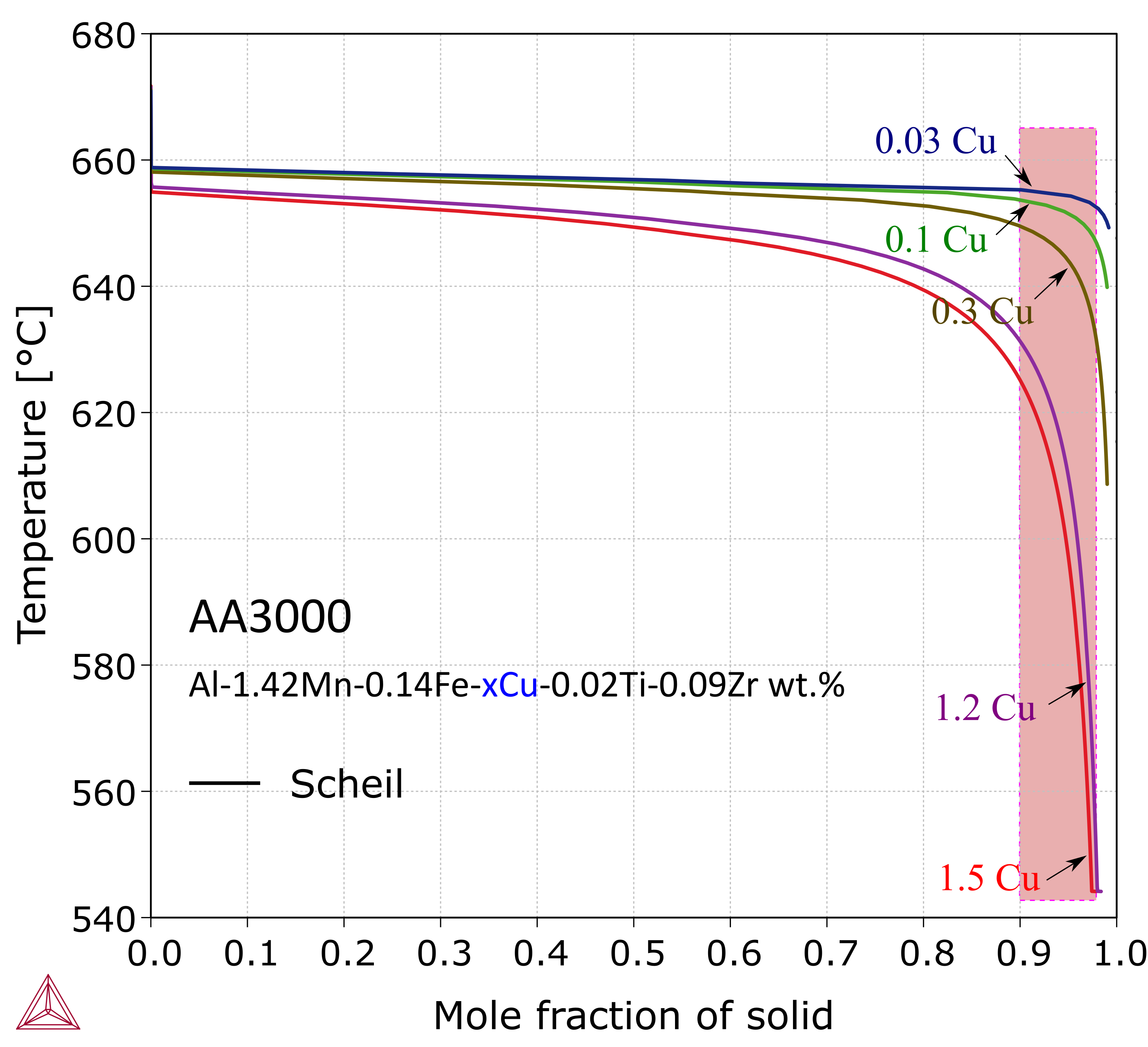

Figure 4: Adding Cu to AA3000 alloy significantly increases the susceptibility and worsens the castability.

3000 Series Alloys with Cu Additions

Figure 5: The recent experimental investigations by Razaz [2019Raz] reported that "a similar increase in HTS with Cu additions from 0.3 to 1.2 wt.% was proven” in 3000 alloys. The data are somewhat scattered because there are three groups of alloys and the contents of the other alloying elements are not exactly the same even for each group, but one can evidently see the trend that HTS increases with Cu additions.

Reference

[2019Raz] G. Razaz, T. Carlberg, Hot Tearing Susceptibility of AA3000 Aluminum Alloy Containing Cu, Ti, and Zr, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., (2019).

![The recent experimental investigations by Razaz [2019][2019, Razaz] G. Razaz, T. Carlberg, Hot Tearing Susceptibility of AA3000 Aluminum Alloy Containing Cu, Ti, and Zr, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., (2019). reported that "a similar increase in HTS with Cu additions from 0.3 to 1.2 wt.% was proven” in 3000 alloys The recent experimental investigations by Razaz [2019][2019, Razaz] G. Razaz, T. Carlberg, Hot Tearing Susceptibility of AA3000 Aluminum Alloy Containing Cu, Ti, and Zr, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., (2019). reported that "a similar increase in HTS with Cu additions from 0.3 to 1.2 wt.% was proven” in 3000 alloys](../../../resources/images/tcal/a3000-cu_tfr_exp.png)