Solidification: Back Diffusion

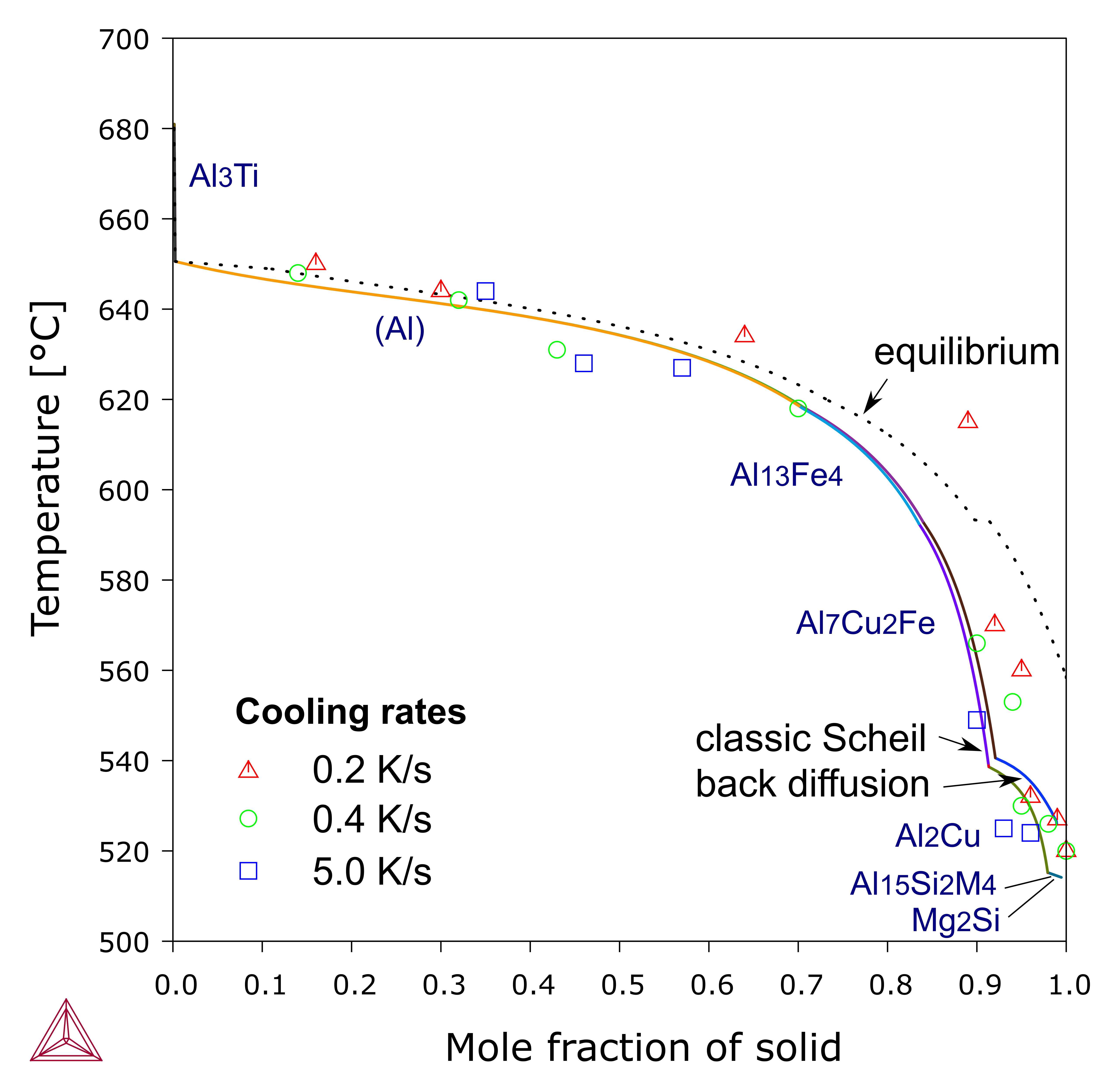

An experimental solidification is usually expected to be between the equilibrium calculation and the classic Scheil simulation. The deviation from a Scheil simulation may be due to the effect of back diffusion. To better predict or account for the phase formation during the experiment, you can run a Scheil simulation considering back diffusion.

Read more about Scheil Solidification Simulations on our website, including how to select the right model for your simulation. If you are in Thermo‑Calc, press F1 to search the help to learn about using Scheil.

The example shows three solidification simulations of the A204.2 foundry alloy. One is run without back diffusion and labeled Classic Scheil. The one with back diffusion is run at a cooling rate of 0.2 K/s. The dashed line shows the results from an equilibrium simulation.

Figure 1: Solidification simulations of foundry alloy 204.2 (Al-Si0.08Fe0.20Cu4.40Mn0.02Mg0.22Ti0.22, wt.%), compared with DTA experimental results [1990Bac]. The formation of (Al), Al13Fe4, Al7Cu2Fe and Al2Cu was reproduced in the Scheil simulation. Al3Ti appeared as the primary phase due to the Ti addition.

Reference

[1990Bac] L. Backerud, G. Chai, J. Tamminen, Solidification Characteristics of Aluminum Alloys in Foundry Alloys, Volume 1 and 2 (American Foundrymen’s Society, Inc., 1990), p. 266.