Homogenization / Solution /Aging Treatment: 6005

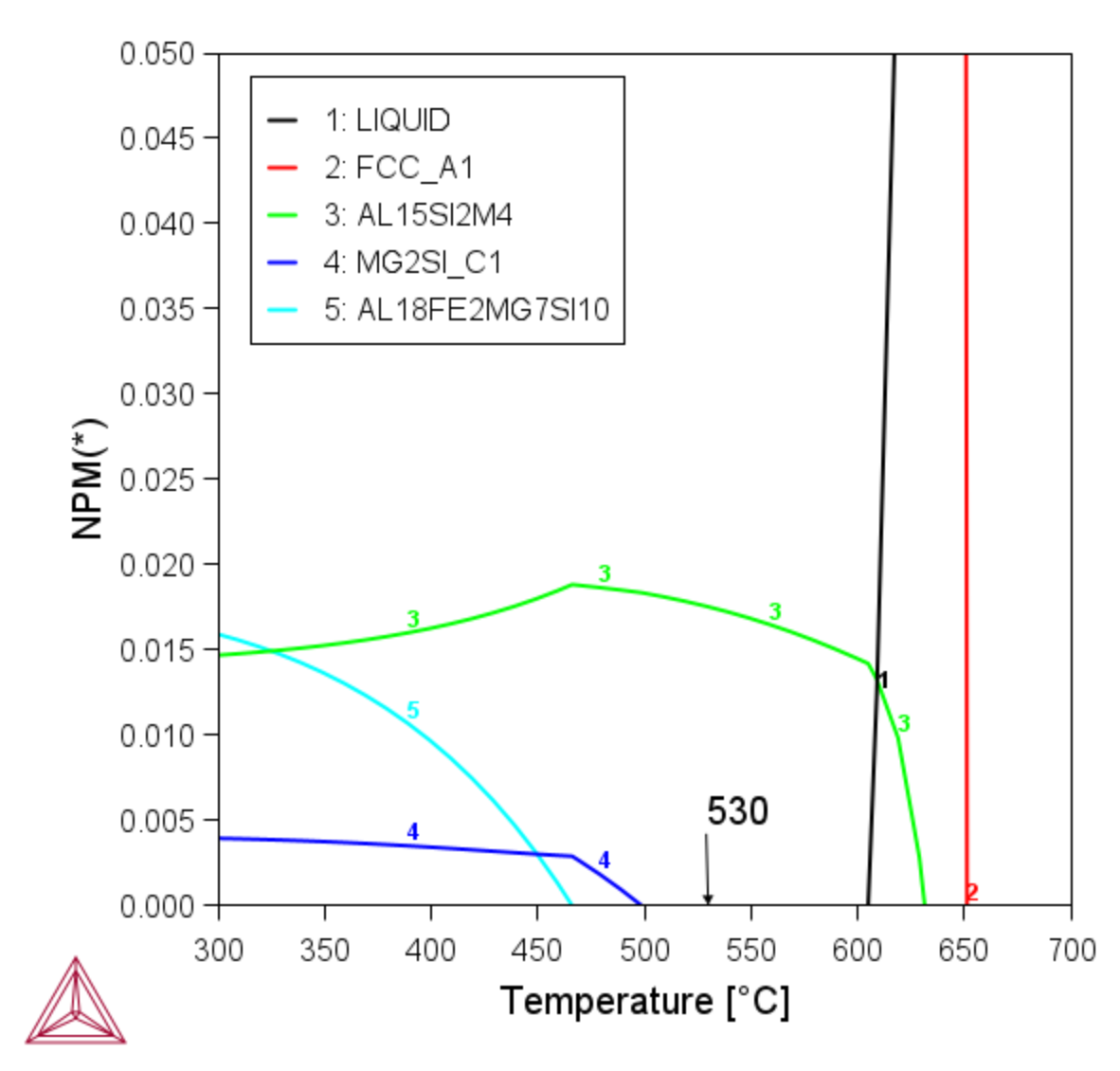

According to this equilibrium calculation using the TCS Al-based Alloy Database (TCAL), it is impossible to attain a single (Al) phase for AA6005 alloy (Al-0.82Si-0.55Mg-0.016Cu-0.5Mn-0.2Fe, wt. %) after a solution treatment.

The temperature of 530 °C was chosen considering these factors:

- it is sufficient high to fully dissolve the Mg2Si compound so as to maximize the amount of precipitates during aging,

- the Al15Si2M4 phase can be dissolved to a large extent, and

- it leaves a margin to the incipient melting.

Figure 1: Equilibrium calculation for AA6005 alloy (Al-0.82Si-0.55Mg-0.016Cu-0.5Mn-0.2Fe, wt. %) after a solution treatment. See the text for discussion.

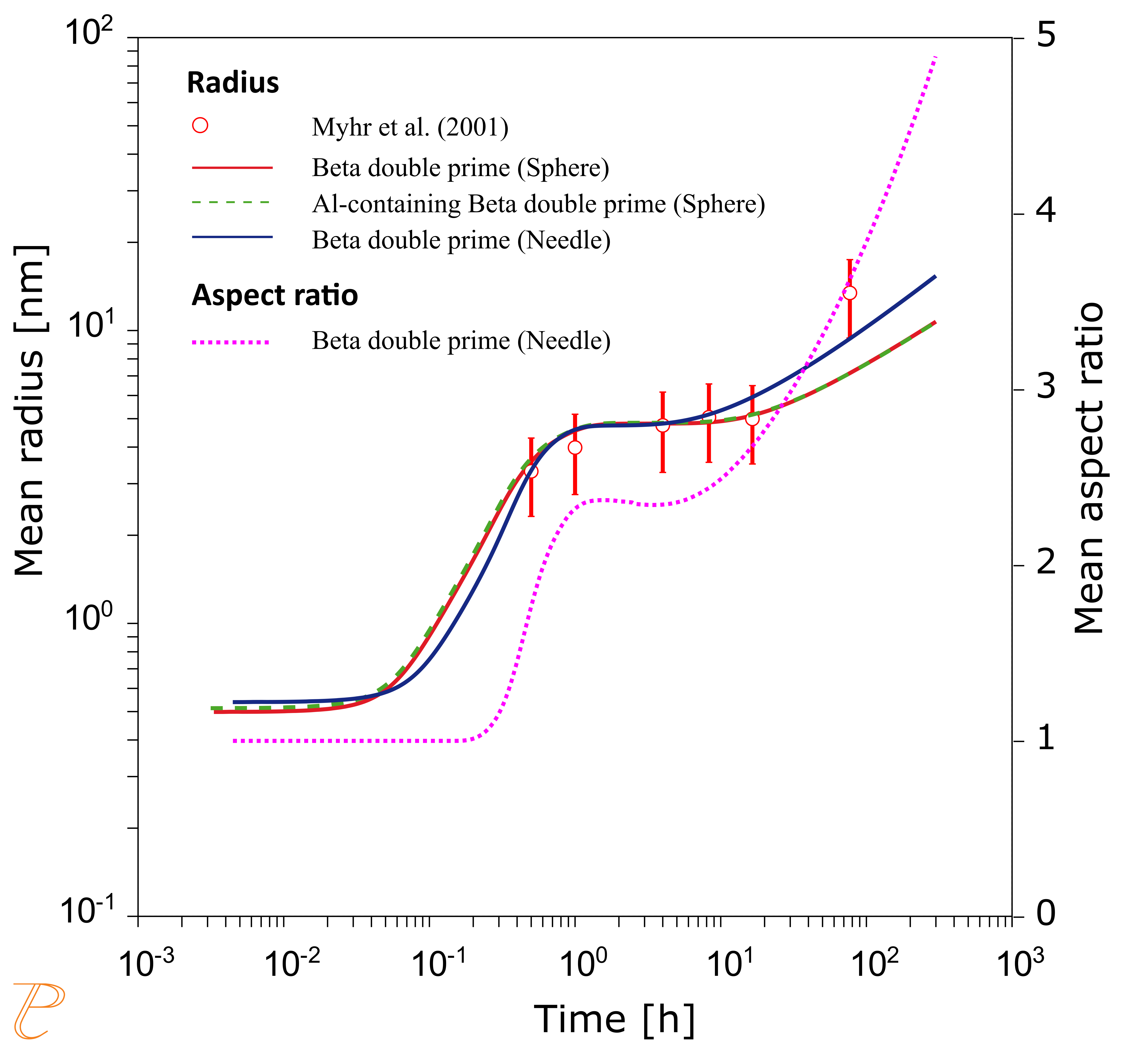

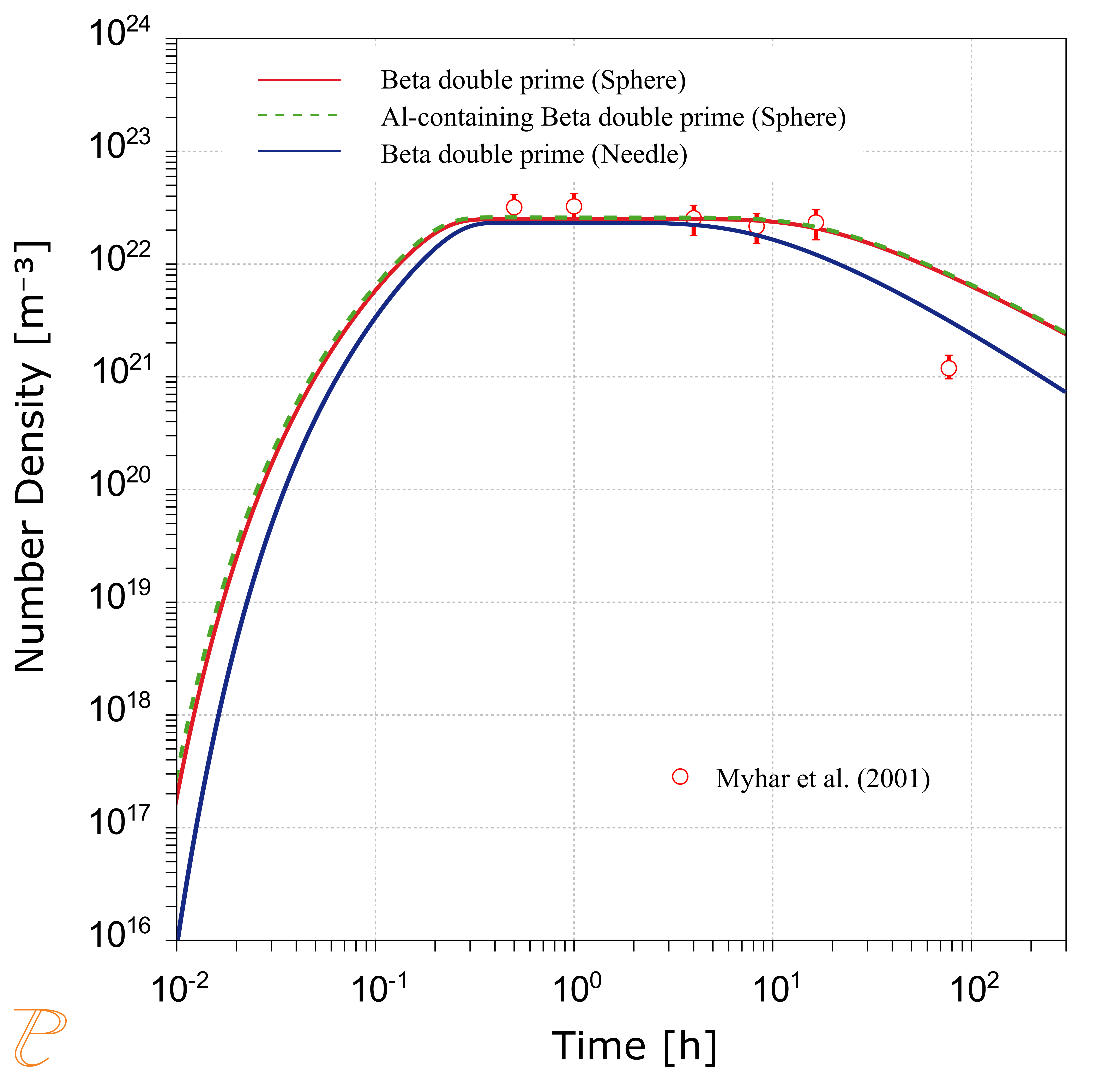

The following example is to simulate the precipitation of β’’ in the (Al) matrix in the 6005 alloy. The composition of the (Al) solution, 0.562 wt.% Mg, 0.016 wt.% Cu, 0.607 wt.% Si, 0.054 wt.% Mn and 0.002 wt.% Fe, was calculated first at the solution treating temperature of 530 °C and it is slightly different from the nominal alloy composition. The figure below shows simulated mean radius and aspect ratio of β'' precipitates at 185 °C.

Read more about the Precipitation Module (TC-PRISMA) on our website. If you are in Thermo‑Calc, press F1 to search the help to learn about the available settings included with the Add-on Module.

Figure 2: Simulated mean radius and aspect ratio of β'' precipitates at 185 °C. This plot uses the add-on Precipitation Module (TC-PRISMA).