Surface Tension of Slag

Surface tension of slag is an important property for mineral processing, metal processing, slagging combustion, and slagging gasification. In the case of slagging gasification, slag properties impact the efficiency, reliability, maintenance cost, and environmental performance of the process [2017Duc]. The calculation of the surface tension using Thermo-Calc and TCS Metal Oxide Solutions Database (TCOX) is validated by comparing with two synthetic slags and one real slag with the various compositions listed in the table below.

| Synthetic coal ash, wt. % | Real Coal ash, wt. % | Synthetic petroleum coke ash, wt. % | |

|---|---|---|---|

| SiO2 | 45.4 | 37.59 | 54.1 |

| Al2O3 | 20.0 | 16.61 | 22.69 |

| Fe2O3 | 6.7 | 5.54 | 8.6 |

| TiO2 | 0.8 | 0.69 | 4.2 |

| P2O5 | - | 0.41 | - |

| CaO | 15.9 | 13.16 | 2.9 |

| MgO | 3.5 | 2.93 | 1.5 |

| Na2O | 7.7 | 6.36 | 0.7 |

| K2O | - | 0.28 | - |

| V2O5 | - | - | 4.1 |

| NiO | - | - | 1.0 |

| MnO | - | 0.0245 | - |

| CuO | - | 0.0076 | - |

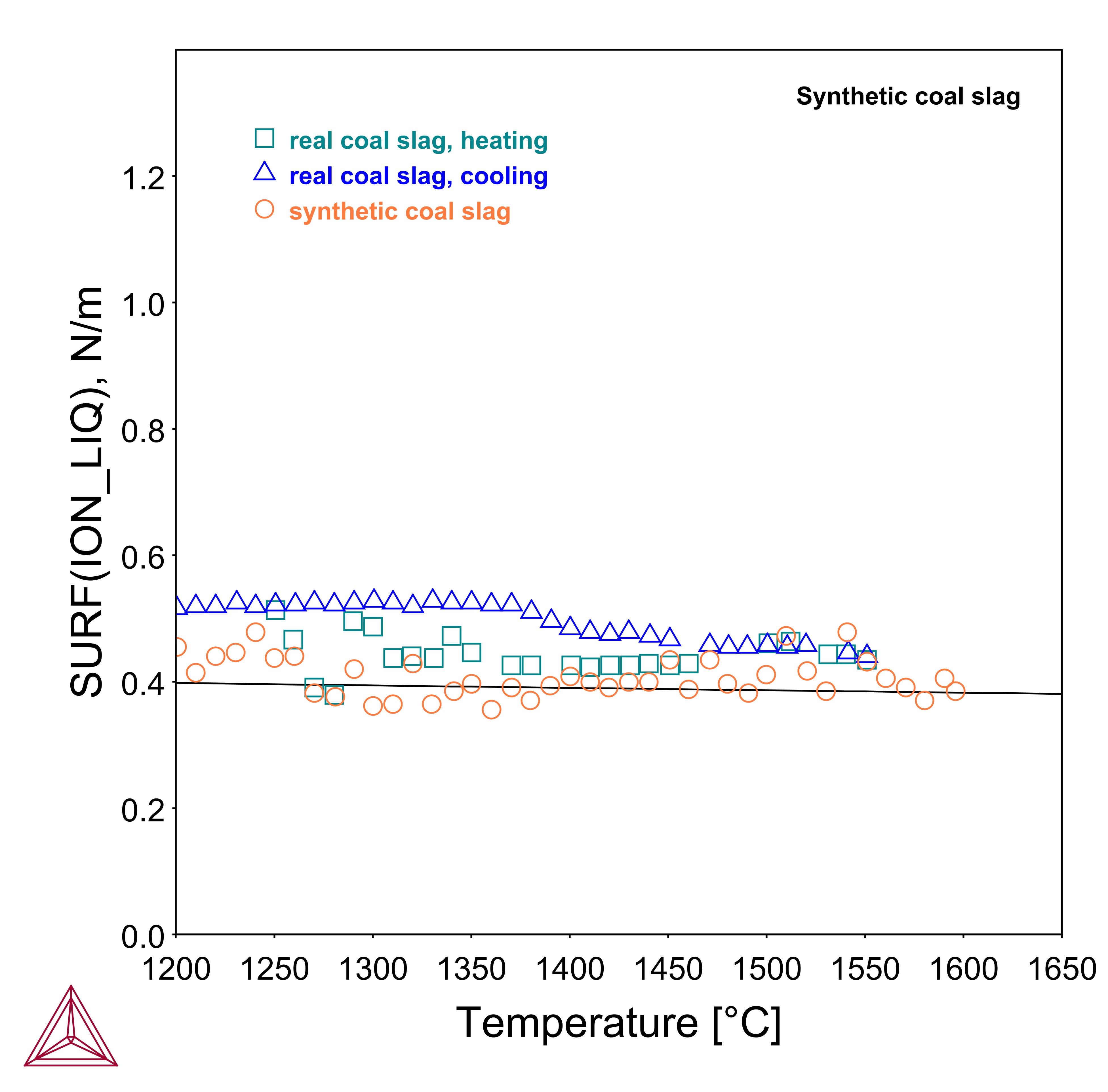

Figure 1: Calculated surface tension under P(O2) =1e-9 bar compared with the surface tension of synthetic coal slag measured on 8 mm substrates of molybdenum in Ar/H2 [2017Duc].

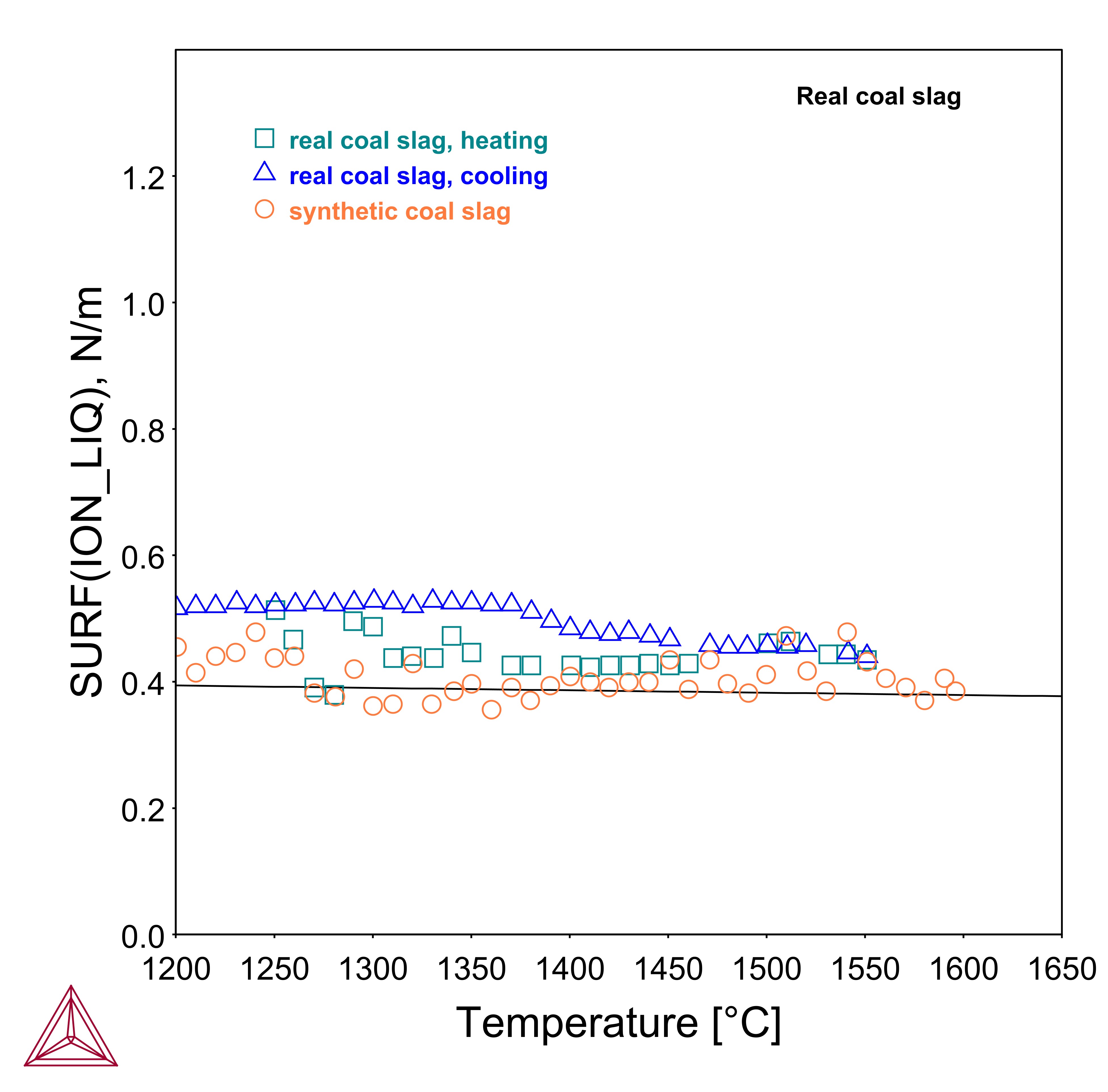

Figure 2: Calculated surface tension under P(O2) =1e-9 bar compared with the surface tension of real coal slag measured on 8 mm substrates of molybdenum in Ar/H2 [2017Duc].

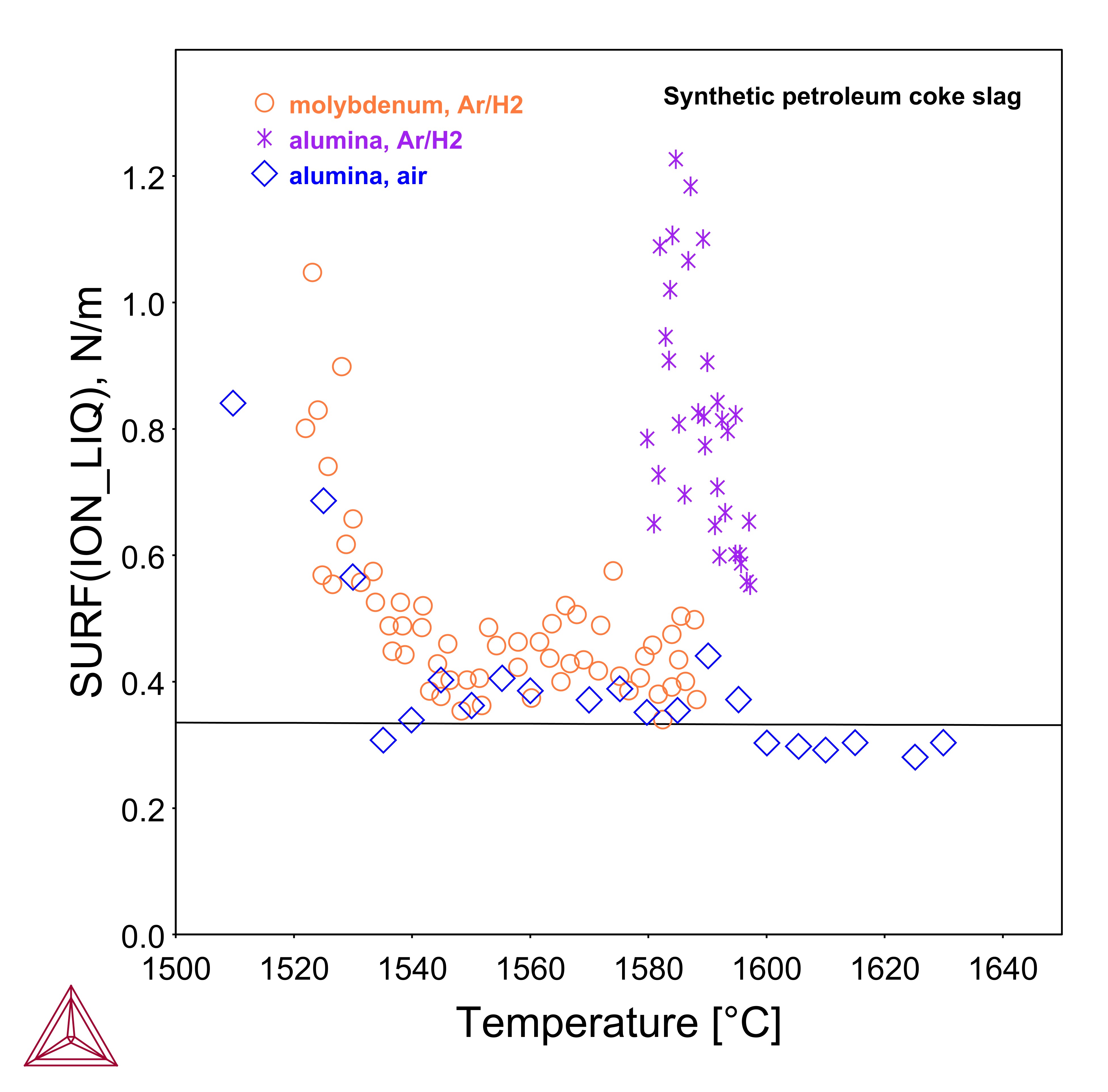

Figure 3: Calculated surface tension in air compared with the surface tension of synthetic petroleum coke slag measured on 8 mm substrates of molybdenum in Ar/H2, alumina in Ar/H2, and alumina in air [2017Duc].

Reference

[2017Duc] M.A. Duchesne, R.W. Hughes, Slag density and surface tension measurements by the constrained sessile drop method, Fuel, 188, 173-181 (2017).