PM_Fe_03: Fe-C-Mn Pearlite

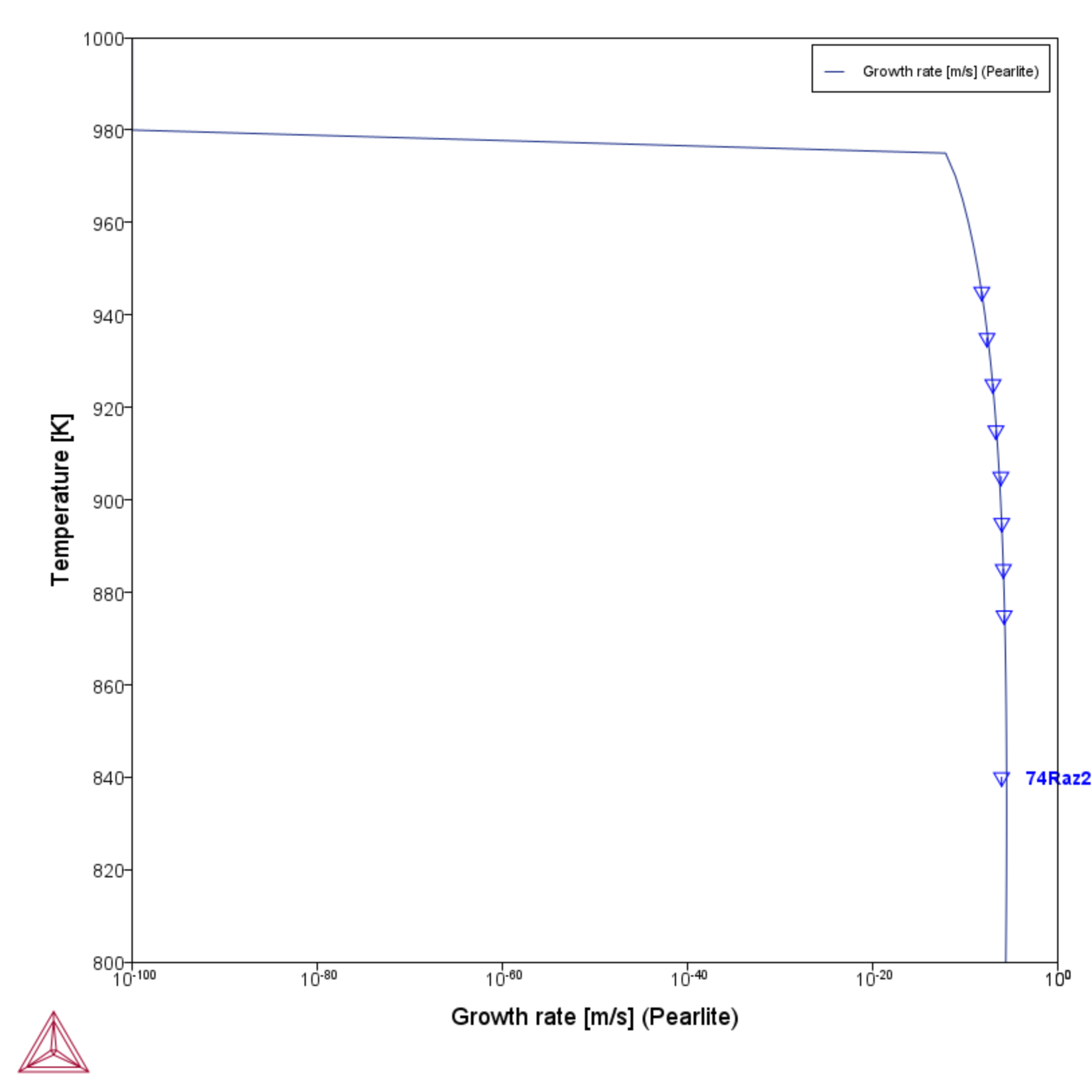

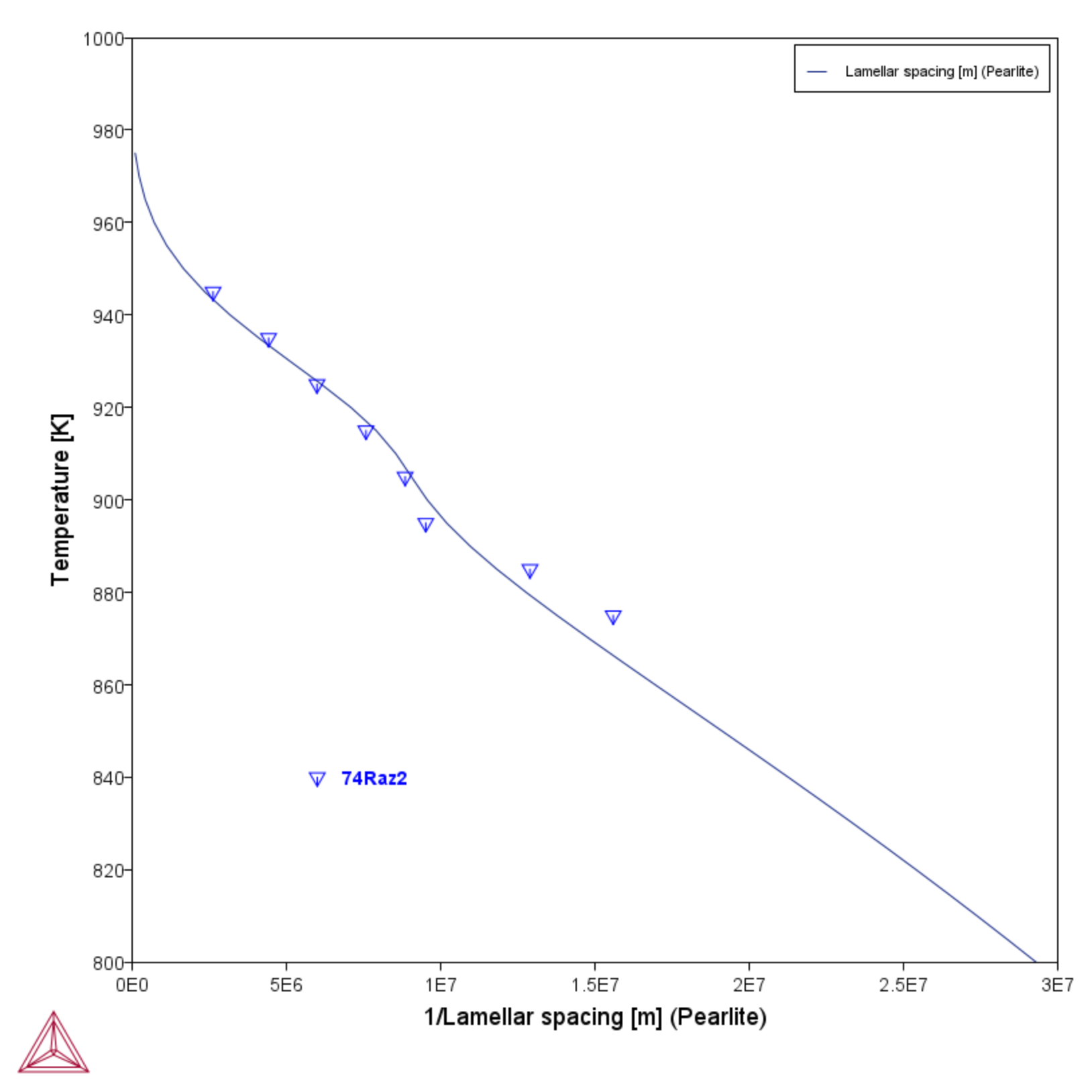

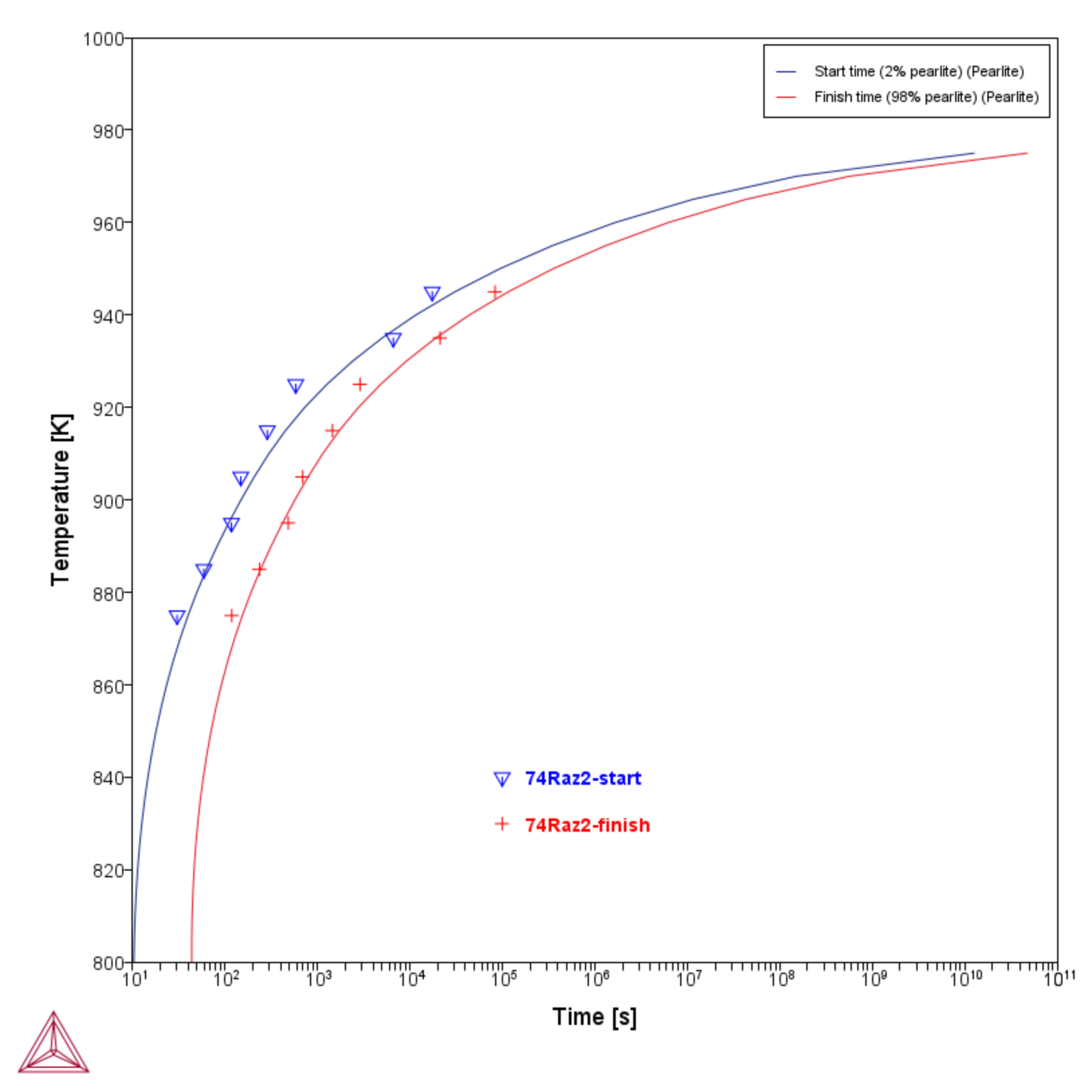

The example uses the Property Model Calculator and with the Pearlite Property Model and shows how to calculate pearlite growth rate, lamellar spacing, and times of start (2% transformation) and finish (98% transformation) as functions of isothermal heat treating temperature in an Fe-0.69C-1.80Mn alloy (mass %). With maximize growth rate set as the criterion, the model gives maximal growth rate and minimal lamellar spacing. With optimal pearlite as the pearlite mode, the model optimizes partitioning of substitutional alloying element(s) (Mn in this example) according to the criterion, which realizes a smooth transition between ortho-pearlite at high temperature and para-pearlite at low temperature.

Property Model Calculator and About the Pearlite Property Model

- Folder: Property Models → Steel

- File name:

PM_Fe_03_Fe-C-Mn_Pearlite.tcu

To run calculations with the Steel Models requires a valid maintenance license plus licenses for both the TCFE (version 9 and newer) and MOBFE (version 4 and newer) databases. Also see our website to learn more about the Steel Model Library and other related examples.

Visualizations

Many of our Graphical Mode examples have video tutorials, which you can access in a variety of ways. When in Thermo‑Calc, from the menu select Help → Video Tutorials, or from the main My Project window, click Video Tutorials. Alternately, you can go to the website or our YouTube channel.

Open the example project file to review the node setup on the Project window and the associated settings on the Configuration window for each node. For some types of projects, you can also adjust settings on the Plot Renderer Configuration window to preview results before performing the simulation. Click Perform Tree to generate plots and tables to see the results on the Visualizations window.

Figure 3: The TTT (time-temperature-transformation) diagram showing times of start (2% transformation) and finish (98% transformation) as functions of isothermal heat treating temperature in an Fe-0.69C-1.80Mn alloy (mass %).

Reference

[1974Raz] N. Razik, G. Lorimer, N. Ridlley, An investigation of manganese partitioning during the austenite-pearlite transformation using analytical electron microscopy. Acta Metall. 22, 1249–1258 (1974).