High-strength Low-alloy Steels (HSLA)

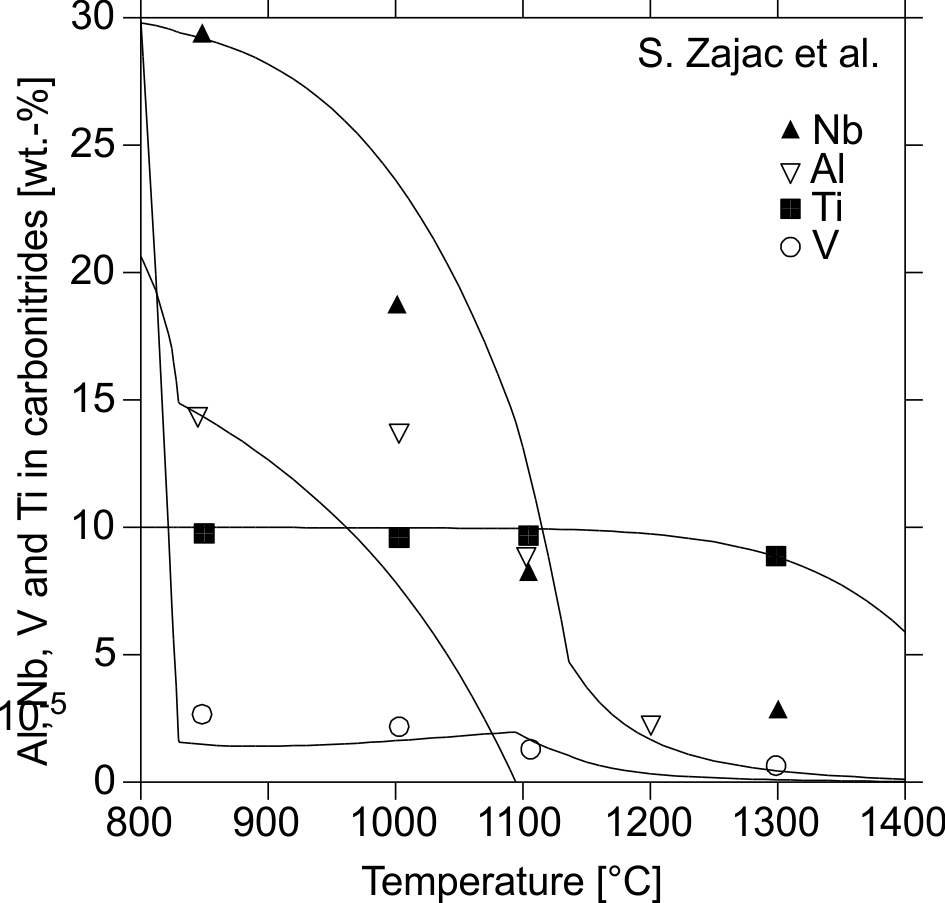

A useful application of the TCS Steel and Fe-alloys Database (TCFE) is for high-strength low alloy (HSLA) steels, especially to predict correct phases and phase compositions in all possible precipitates.

Figure 1: Predicted mass fraction of Nb, Ti, V, and Al in precipitates compared with experimental information [1998Zaj] for a microalloyed steel with 0.09C-1.51Mn-0.035Al-0.010Ti-0.030Nb-0.08V-0.0105N (wt.%).

The tables below show the predicted compositions for (TixNb1-x)NyC1-y and (NbtTi1-t)CuN1-u carbonitrides (site fractions) in two microalloyed steels compared with measurements from [2000Cra]. All calculations were made at 1000 °C. Both steels contain the following alloy contents: 0.036Al- 1.4Mn-0.50Ni-0.015P-0.002S-0.4Si (wt.%) in addition to the composition provided.

| Steel 1 |

0.07C wt.% |

0.0079N wt.% |

0.025Nb wt.% |

0.009Ti wt.% |

|---|---|---|---|---|

|

x |

y |

t |

u |

|

|

Experiment |

0.86 ± 0.04 |

≈ 1 |

1 |

≈ 0.7 |

|

Calculation |

0.95 |

0.94 |

0.99 |

0.71 |

|

Steel 2 |

0.097%C |

0.0049%N |

0.017%Nb |

0.010%Ti |

|---|---|---|---|---|

|

x |

y |

t |

u |

|

|

Experiment |

0.91 ± 0.03 |

0.84 ± 0.05 |

1 or ≈ 0.8 |

≈ 1 |

|

Calculation |

0.97 |

0.92 |

0.98 |

0.78 |

References

[1998Zaj] S. Zajac, R. Lagneborg, Thermodynamic model for the precipitation of carbonitrides in microalloyed steels - Internal report IM-3566, Swedish Institute for Metals Research, Stockholm, Sweden, 112 pp. (1998).

[2000Cra] A. Craven, K. He, L. A. J. Garvie, and T. N. Baker, Complex heterogeneous precipitation in titanium–niobium microalloyed Al-killed HSLA steels—I. (Ti,Nb)(C,N) particles, Acta Mater., 48 (15), pp. 3857–3868 (2000).