Low-density Steels

Al-C-Cr-Fe-Mn-Ni

Reducing the weight of engineering structures saves both material and energy, and also leads to greater fuel efficiency and reduces emissions in automobiles. The Al-C-Cr-Fe-Mn-Ni system is the core of low density steels and allows studies to replace costly Ni and Cr in stainless steels by cheaper Mn and Al. The TCS Steel and Fe-alloys Database (TCFE) has the latest assessments and experimental information for the Al-C-Cr-Fe-Mn-Ni system and subsystems.

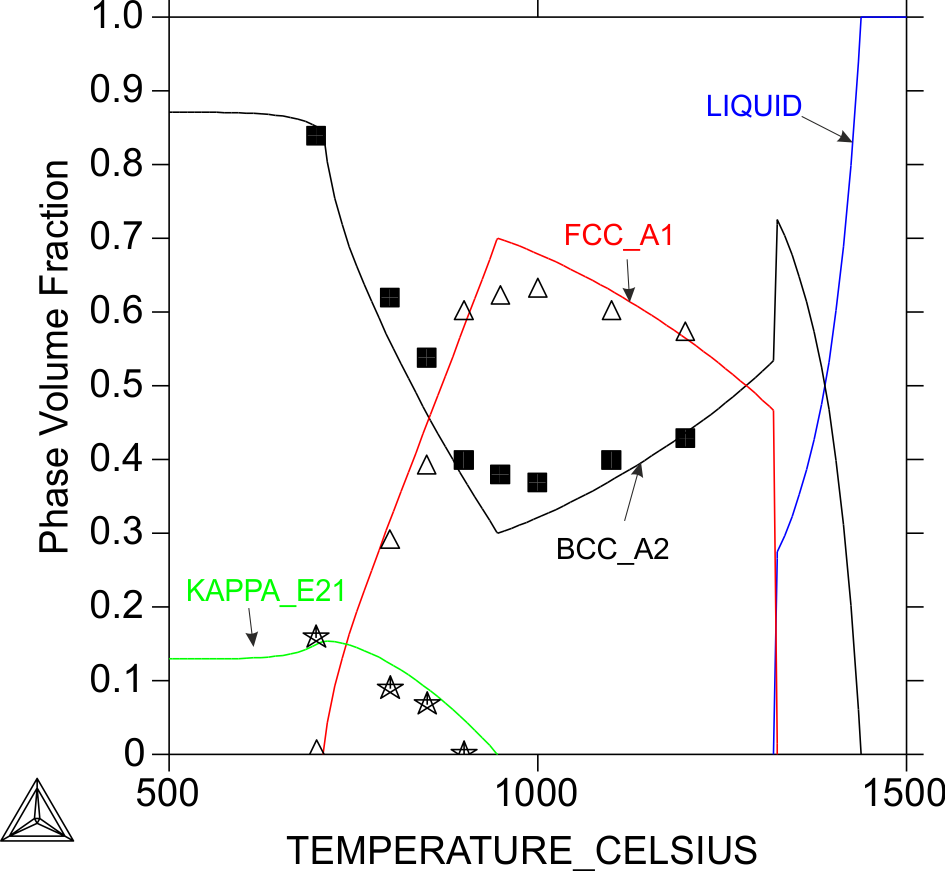

Figure 1: The mole fraction change of each phase with the temperature for Fe‑10Mn-10Al-0.7C low-density steel [2016Zha].

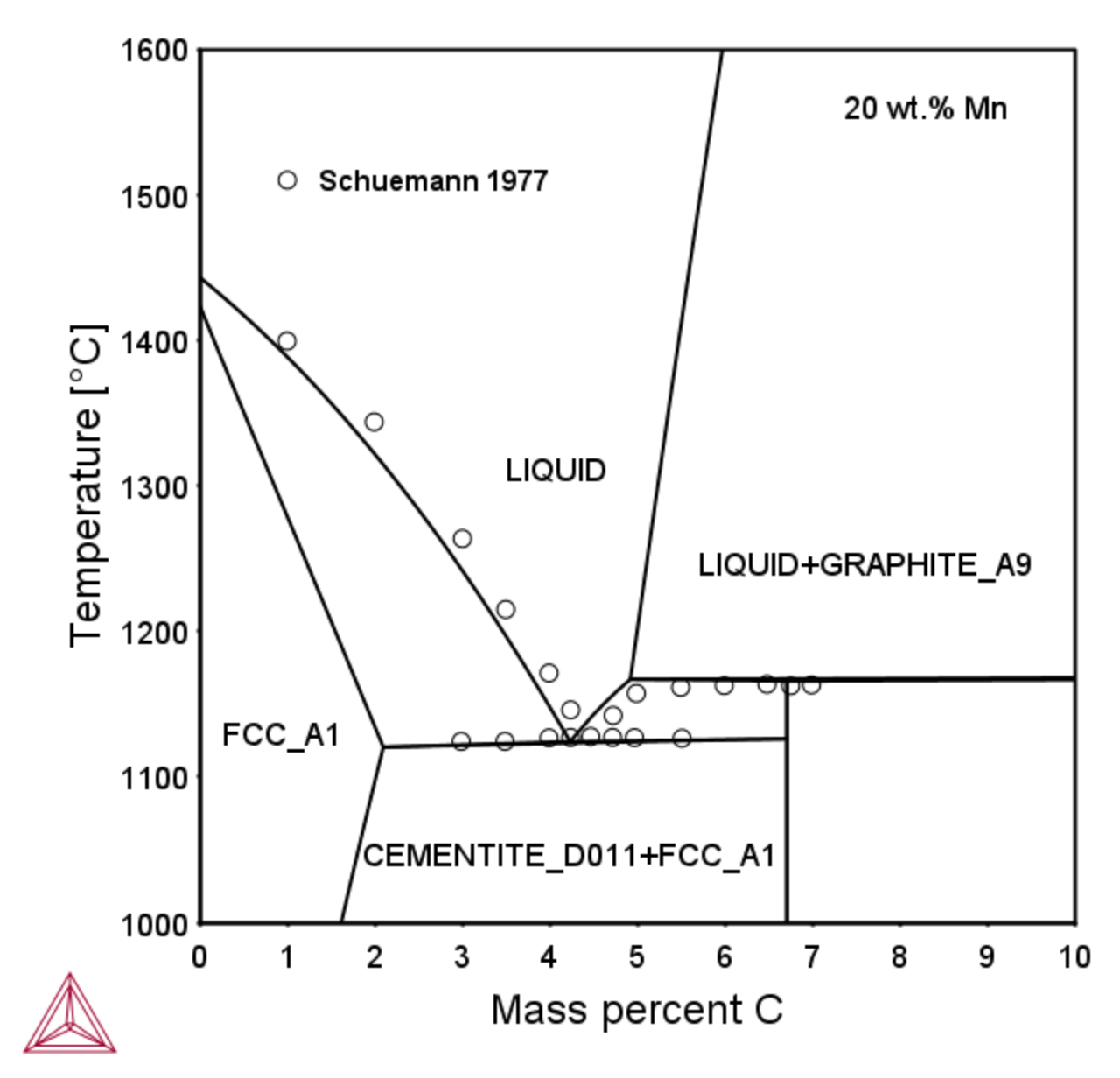

Figure 2: The calculated vertical section of C-Fe-Mn involving the liquid phase at 20 wt.% Mn compare to the experimental data as cited by [2011Dju].

Comparing FCC_A1 to BCC_B2 Composition

It has been shown [2015Kim] that a B2-type brittle but hard intermetallic compound can be effectively used as a strengthening second phase in high-aluminum low-density steel. The table shows a comparison of the calculated partitioning of alloying elements between B2 precipitate and austenite matrix during annealing of cold rolled Fe-10Al-15Mn-0.8C-5Ni (at.%), with the experimental observations.

| Element | FCC_A1 composition (at.%) |

BCC_B2 composition (at.%) |

||

|---|---|---|---|---|

| Calculated | Experiment [2015Kim] | Calculated | Experiment [2015Kim] | |

|

Fe |

65.4 |

68 |

54.4 |

57.0 |

|

Al |

15.2 |

13 |

25.0 |

22.6 |

|

Mn |

17.0 |

16.6 |

10.0 |

9.4 |

|

Ni |

1.8 |

2.4 |

10.0 |

11.0 |

References

[2011Dju] D. Djurovic, B. Hallstedt, J. von Appen, R. Dronskowski, Thermodynamic assessment of the Fe–Mn–C system, Calphad. 35, 479–491 (2011).

[2015Kim] S.-H. Kim, H. Kim, N. J. Kim, Brittle intermetallic compound makes ultrastrong low-density steel with large ductility, Nature. 518, 77–79 (2015).

[2016Zha] C. Zhao, R. Song, L. Zhang, F. Yang, T. Kang, Effect of annealing temperature on the microstructure and tensile properties of Fe–10Mn–10Al–0.7C low-density steel, Mater. Des. 91, 348–360 (2016).