Oxidation

The TCS Steel and Fe-alloys Database (TCFE) includes the description of the oxide phases such as SPINEL, HALITE, and CORUNDUM for the Fe-Al-Ca-Cr-Mg-Mn-Ni-Si-Ti-C-O system [2009Kje], which allows for accurate predictions in different fields, e.g. oxide scale formation on various steels.

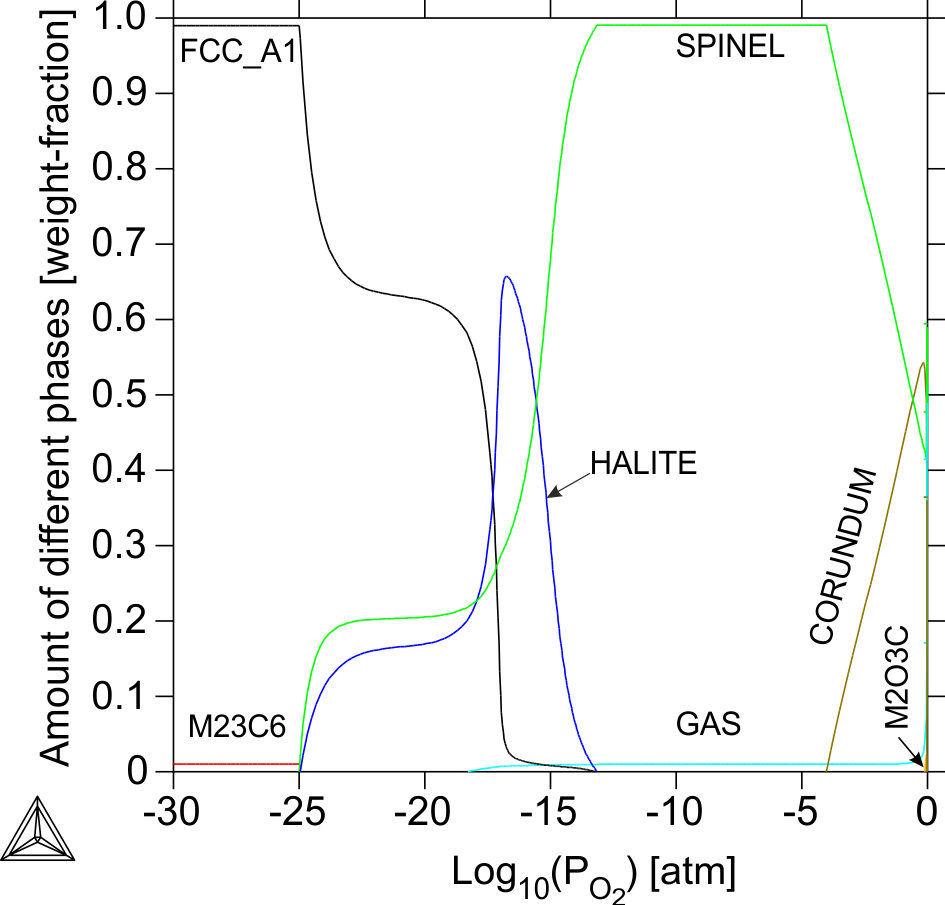

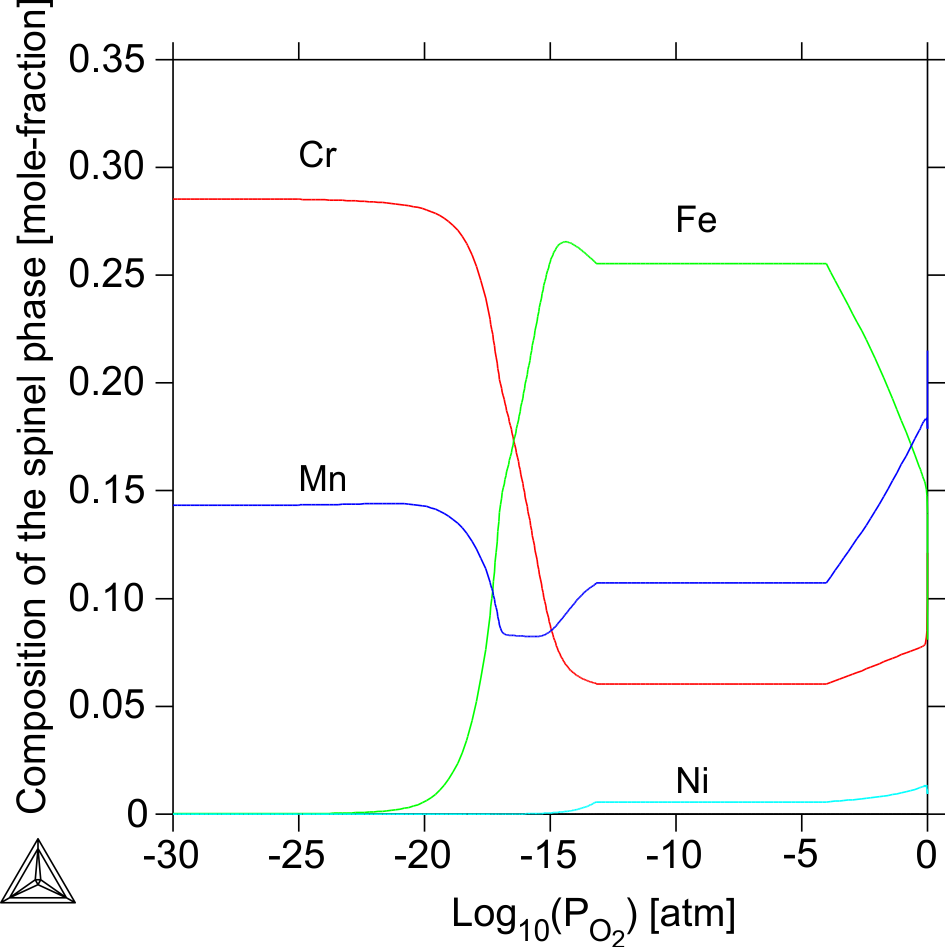

For example, in these plots the oxide scale formed on a steel is predicted and the agreement with experimental information [1984Wan; 1986Dou; 1991Nan; 2004Kur] is very good. You can see that below the outer scale (rich in corundum) an Fe-Mn spinel is formed and closest to the substrate a layer with halite and a Cr-Mn rich spinel, which also is verified in the work by Douglass et al. [1986Dou].

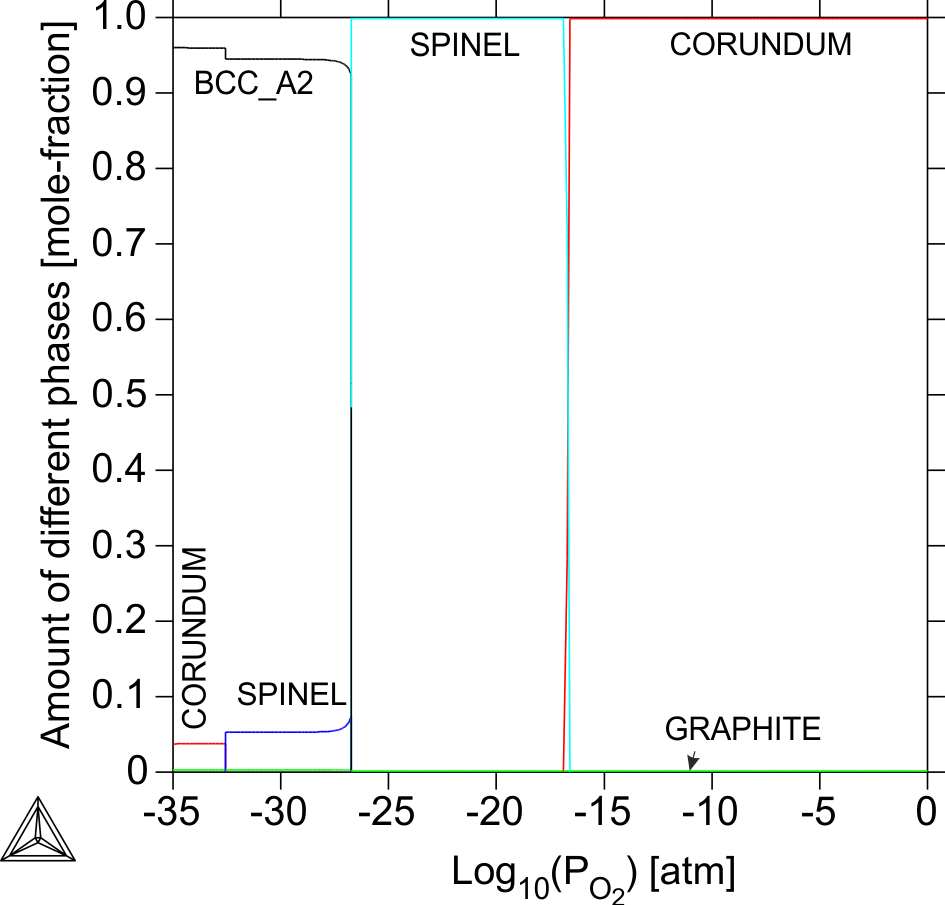

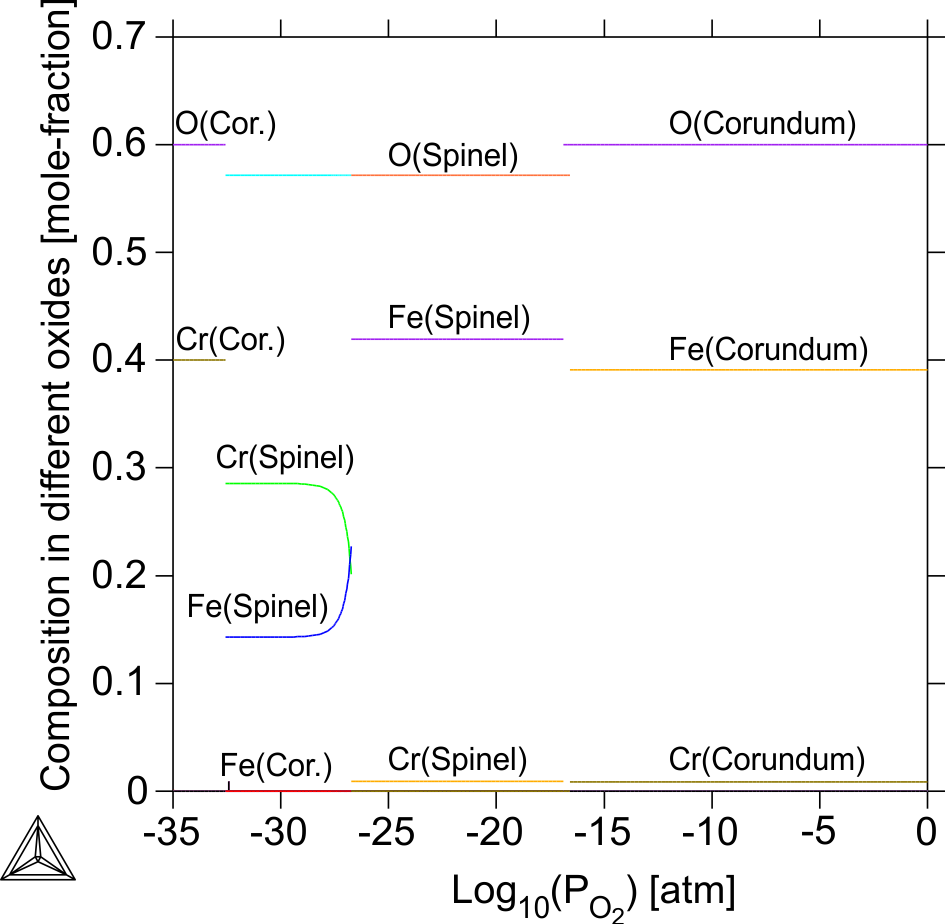

Figure 4: Calculated composition in different oxides versus oxygen partial pressure for the low-Cr boiler steel (Fe-1.44Cr-0.06C wt.%). These results agree very well compared with experimental information [2005Tri]. A small amount of graphite is present for the whole oxygen partial pressure interval.

The model used for the spinel and corundum phases makes it possible to simulate diffusion inside these phases using the Diffusion Module (DICTRA) (also possible for other oxides such as halite) provided that a suitable mobility database is available.

Read more about the Diffusion Module (DICTRA) on our website. There is also a Getting Started with the Diffusion Module (DICTRA) page available. If you are in Thermo‑Calc, press F1 to search the help to learn about the available settings included with the Add-on Module.

References

[1984Wan] R. Wang, M. J. Straszheim, R. A. Rapp, A high-temperature oxidation-resistant Fe-Mn-Al-Si alloy, Oxid. Met. 21, 71–79 (1984).

[1986Dou] D. L. Douglass, F. Gesmundo, C. de Asmundis, The air oxidation of an austenitic Fe-Mn-Cr stainless steel for fusion-reactor applications, Oxid. Met. 25, 235–268 (1986).

[1991Nan] P. Nanni, V. Buscaglia, G. Battilana, E. Ruedl, Air oxidation of a Mn-Cr austenitic steel of potential use for fusion reactor structural applications between 1073 and 1473 K at 105 Pa, J. Nucl. Mater. 182, 118–127 (1991).

[2004Kur] H. Kurokawa, K. Kawamura, T. Maruyama, Oxidation behavior of Fe–16Cr alloy interconnect for SOFC under hydrogen potential gradient, Solid State Ionics. 168, 13–21 (2004).

[2005Tri] V. B. Trindade, U. Krupp, H.-J. Christ, M. J. Monteiro, F. C. Rizzo, Experimental Characterization and Computer-Based Simulation of Thermodynamics and Kinetics of Corrosion of Steels at High Temperatures, Materwiss. Werksttech. 36, 471–476 (2005).

[2009Kje] L. Kjellqvist, Thermodynamic description of the Fe-C-Cr-Mn-Ni-O system, PhD thesis, KTH Royal Institute of Technology, Stockholm, Sweden (2009).