Dynamic and Kinematic Viscosity of Various Alloys

The TCS Steel and Fe-alloys Database (TCFE) can be used to calculate the viscosity of the metallic liquid. Below are a few examples of the calculated viscosity curves compared with experimental data. The viscosity thermophysical property data is included starting with version 10 (TCFE10).

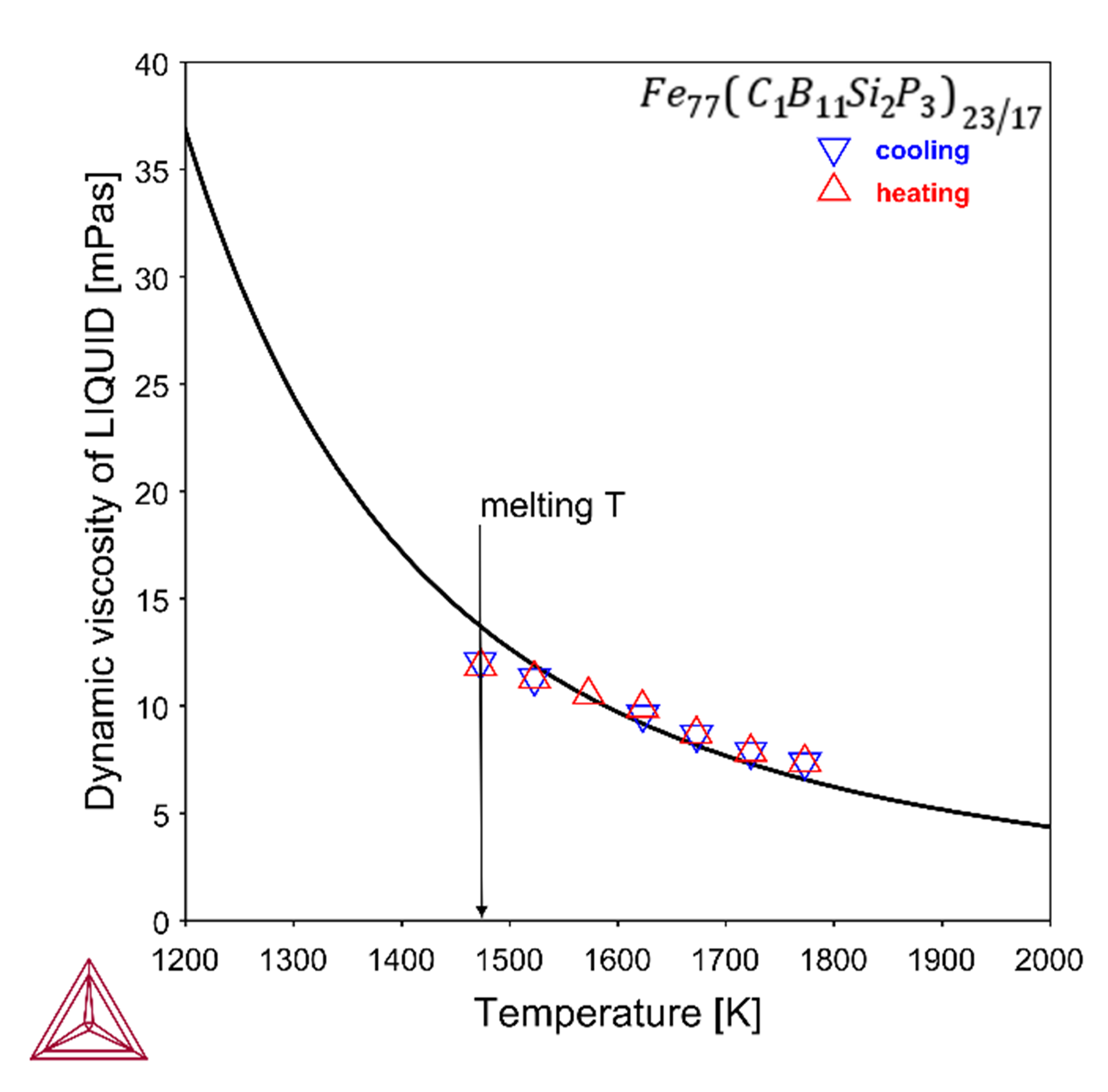

Fe-C-B-Si-P Alloy

Calculated dynamic viscosity of an Fe-C-B-Si-P alloy is compared with experimental data.

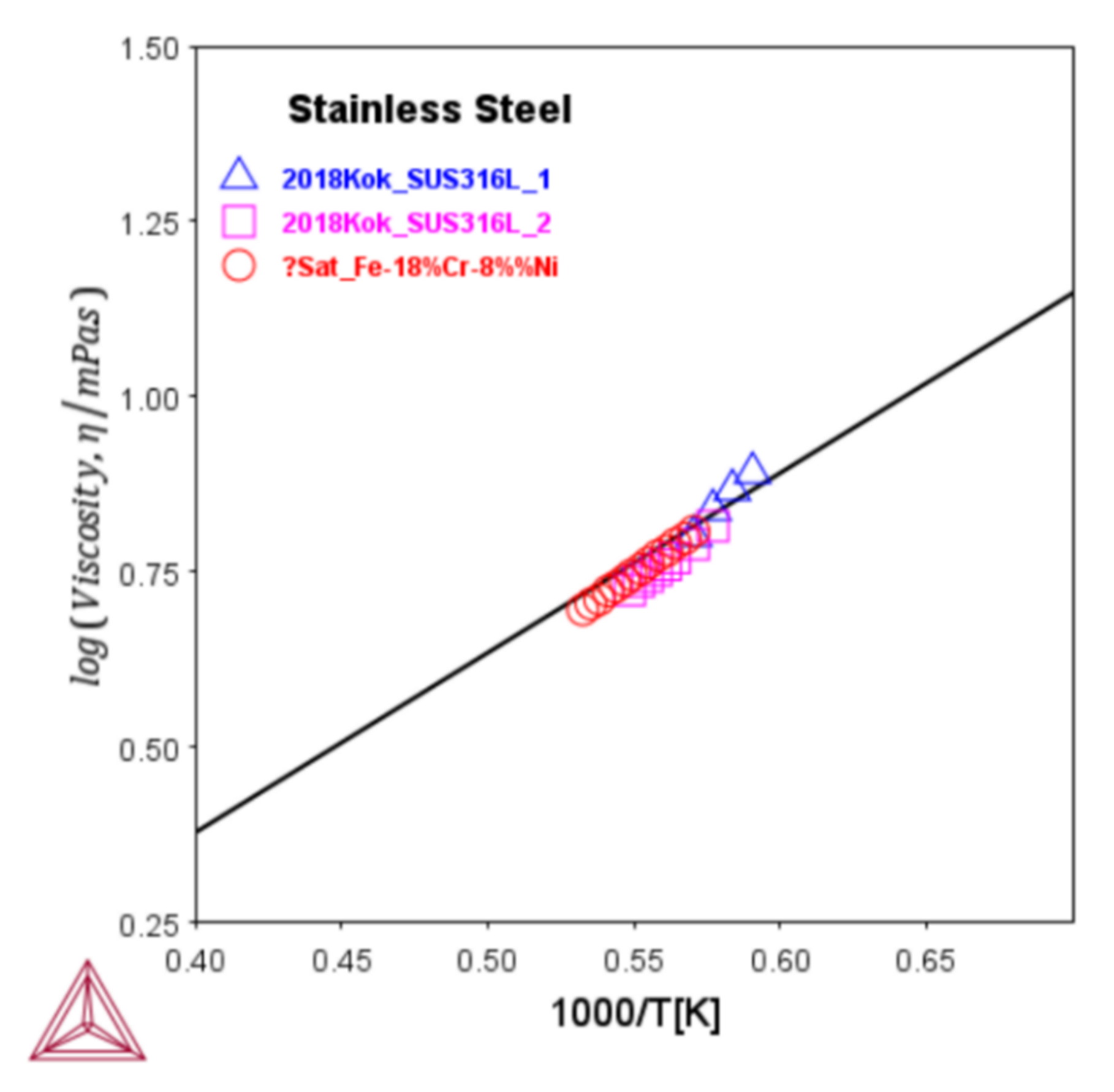

Stainless Steel

The viscosity of molten stainless steel (SUS316L) was measured by oscillating cup method. The figure shows the calculated viscosity of stainless steel. The experimental data from two measurement runs are imposed on the plot. Also, the measured viscosity of the ternary Fe-18Cr-8Ni wt% which is close in composition to SUS316L is shown.

These data are digitized from [2018Kok] due to inaccessibility to the original paper by Sato et al. [2005Sat].

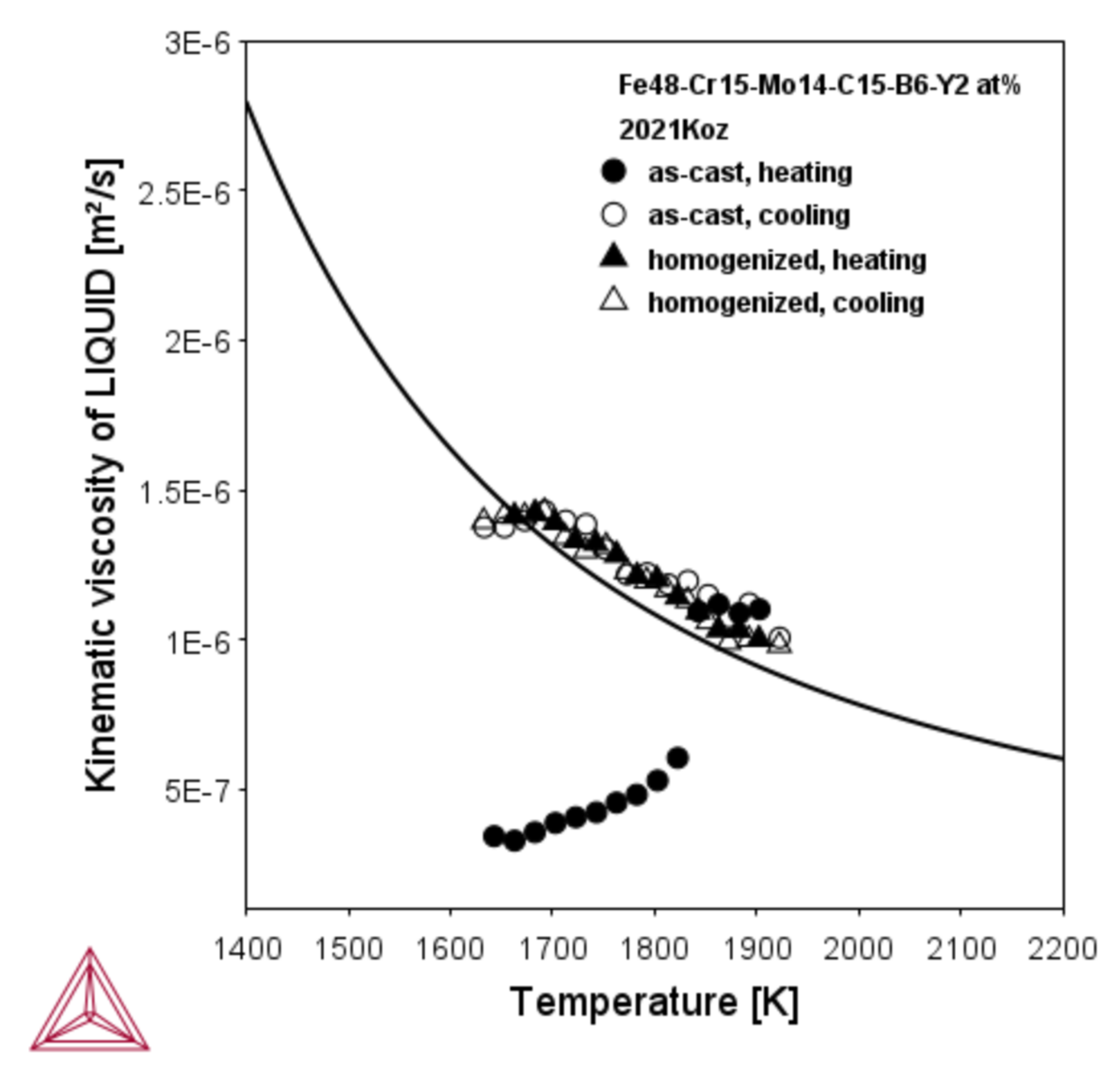

Fe-based Amorphous Alloy

Fe48Cr15Mo14C15B6Y2 is an Fe-based amorphous alloy which is of interest for its glass forming properties. Its kinematic viscosity has recently been measured by Kozak et al. [2021Koz] by means of the damped torsional oscillations of a BeO vessel during heating and subsequent cooling. The measurements are performed on the as-cast alloy as well as the homogenized alloy at 1650 °C.

Figure 3: Calculated kinematic viscosity of Fe48Cr15Mo14C15B6Y2 alloy along with experimental data from [2021Koz].

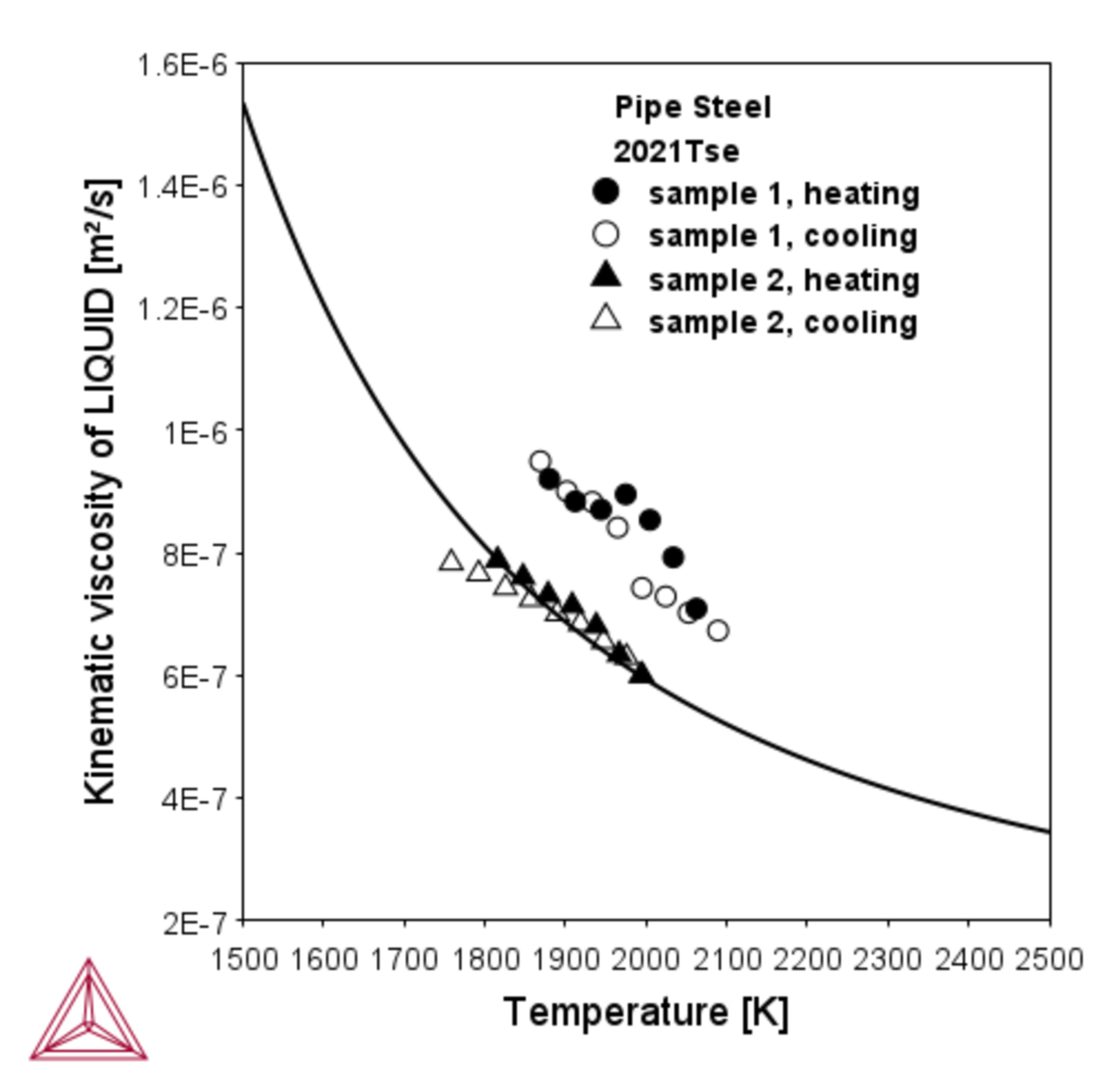

Pipe Steel

Tsepelev et al. [2021Tse] measured the kinematic viscosity of pipe steel. They used two samples; the first one was used in the measurements after melting without degassing (sample 1) but the second sample was degassed after melting (sample 2). The compositions of sample 1 and 2 as reported in the paper are (in w%):

| Fe | C | Si | Mn | Al | Cr | Ni | Cu | P | N | S | O | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample 1 | Balance | 0.21 | 0.28 | 1.05 | 0.022 | 0.100 | 0.100 | 0.22 | 0.010 | 0.009 | 0.0030 | 0.079 |

| Sample 2 | Balance | 0.22 | 0.26 | 0.83 | 0.028 | 0.050 | 0.060 | 0.17 | 0.012 | 0.007 | 0.0006 | 0.034 |

Figure 4: Kinematic viscosity of pipe steel along with experimental data from [2021Tse]. The composition of sample 1 and sample 2 are very close but sample 2 has been degassed after melting while sample 1 has not.

References

[2005Sat] Y. Sato, K. Sugisawa, D. Aoki, T. Yamamura, Viscosities of Fe–Ni, Fe–Co and Ni–Co binary melts. Meas. Sci. Technol. 16, 363–371 (2005).

[2018Kok] H. Kokubo, T. Nishi, H. Ohta, H. Yamano, Viscosity Measurement of Nickel and Stainless Steel Aiming at Systematic Viscosity Measurement for Molten Mixture of Stainless Steel and Boron-Carbide. J. Japan Inst. Met. Mater. 82, 400–402 (2018).

[2018Li] Y. Li, W. Chen, B. Dong, S. Zhou, Effects of metalloid content on viscosity of Fe-Si-B-P-C alloy melt. J. Non. Cryst. Solids. 490, 31–34 (2018).

[2021Koz] D. S. Kozak, V. S. Tsepelev, V. V Konaskov, V. V Vyukhin, V. Y. Zadorozhnyy, A. I. Bazlov, A. R. Kvaratskheliya, A. A. Tsarkov, J. F. M. Van Impe, Thermophysical Properties of the Fe48Cr15Mo14C15B6Y2 Alloy in Liquid State. Metals (Basel). 11, 823 (2021).

[2021Tse] V. S. Tsepelev, Y. N. Starodubtsev, N. P. Tsepeleva, Thermophysical Properties of Pipe Steel in the Liquid State. Metals (Basel). 11, 1099 (2021).