Solidification Simulations

The final step of the reflow process is the solidification of the solder. Though the solidification behavior of solder is also influenced by the consuming of elements during interface reactions, the analysis of the solidification of solder itself can still provide insight on the actual solidification process of the solder. With solidification simulations, the phase formation sequence, phase fraction, phase transformation temperatures and so forth, can be predicted using Thermo‑Calc and the TCS Solder Alloy Solutions Database (TCSLD).

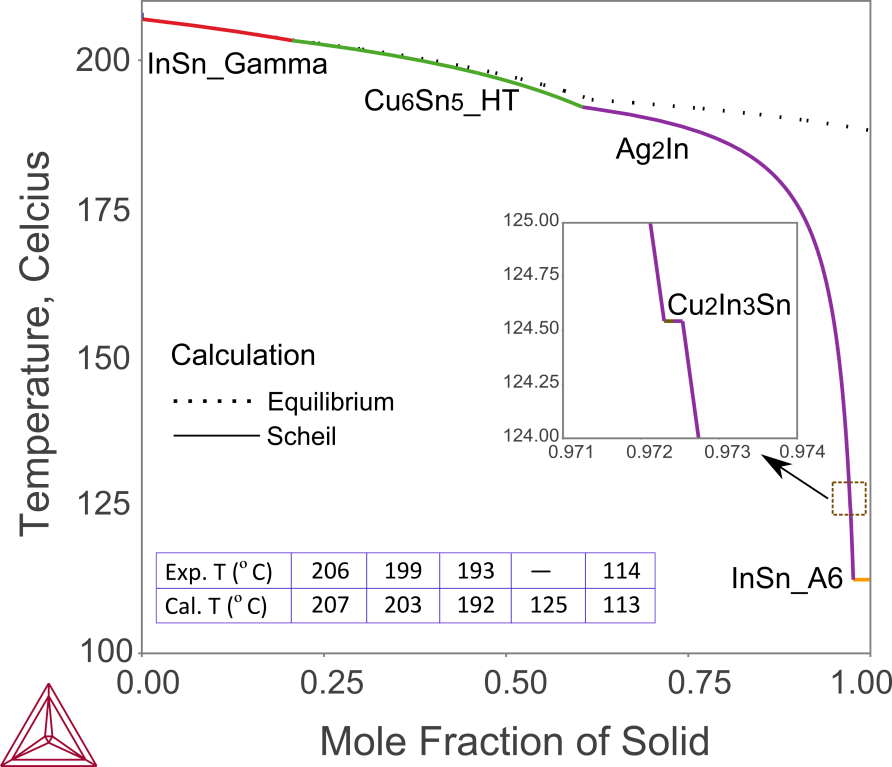

In industry application, non-equilibrium solidification rather than equilibrium solidification is usually observed. The plot simulates both the equilibrium solidification and Scheil (non-equilibrium) solidification of a Sn-Ag-Cu-In alloy.

The calculated Scheil solidification path, including the solidified phases and the phase transformation temperatures, agrees well with the experimental data. It should be noted that the fraction of the Cu2In3Sn phase was very small which is difficult to be detected in the experiment.

Read more about Scheil Solidification Simulations on our website, including how to select the right model for your simulation. If you are in Thermo‑Calc, press F1 to search the help to learn about using Scheil.

Figure 1: Equilibrium solidification and Scheil solidification simulations of a new type of solder patented in Korea with composition Sn-1.5Ag-0.7Cu-9.5In (wt.%) [2008Lee] compared with experimental results [2010Sop].

References

[2008Lee] J.-H. Lee, C.-W. Lee, J. H. Kim, J. H. Kim, Quaternary Pb-free solder composition incorporating Sn-Ag-Cu-In (2008), (available at http://www.patentsencyclopedia.com/app/20080292493).

[2010Sop] J. Sopoušek, M. Palcut, E. Hodúlová, J. Janovec, Thermal Analysis of the Sn-Ag-Cu-In Solder Alloy. J. Electron. Mater. 39, 312–317 (2010).