P_05: Precipitation of γ’ in Ni Superalloys - Isothermal

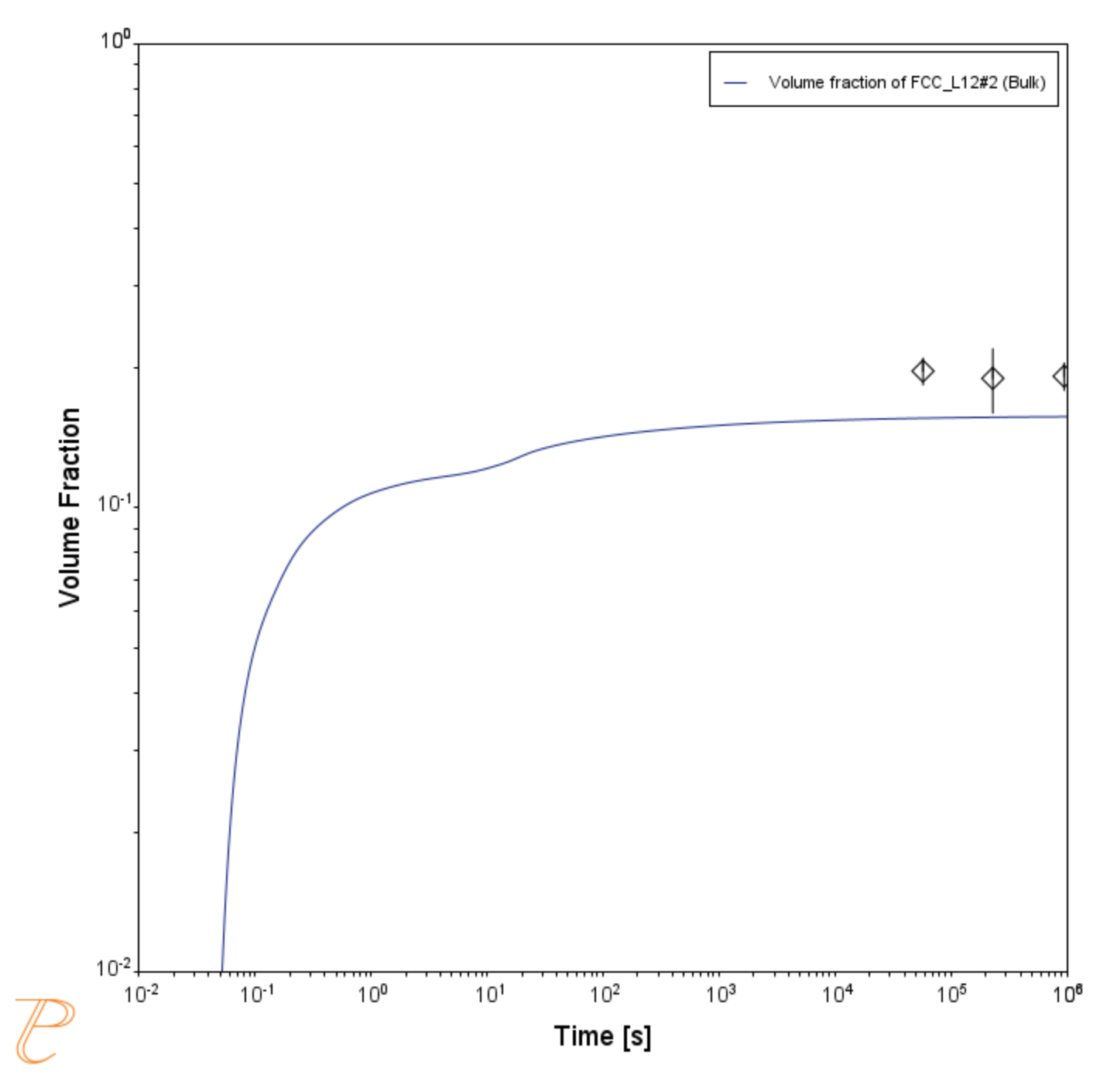

This example simulates the kinetics of precipitation of gamma prime (γ’) phase from gamma (γ) phase. The simulation results can be compared with experimental data collected from Sudbrack et al. [2008Sud].

This example uses three Experimental File Reader activities with the Precipitation Calculator. It does an isothermal calculation to plot the volume fraction, mean radius, and number density of the cementite phase.

DIS_FCC_A1 needs to be selected on the System Definer.

- Folder: Precipitation Module - TC-PRISMA

- File name:

P_05_Precipitation_Ni-Al-Cr_Isothermal_Gamma-Gamma_prime.tcu

Example Settings

| System (System Definer) | |

| Database package | Demo: Nickel-based Super Alloys (NIDEMO and MNIDEMO) |

| Elements | Ni, Al Cr |

| Conditions (Precipitation Calculator) | |

| Composition | Ni-9.8Al-8.3Cr Mole percent |

| Matrix phase |

DIS-FCC_A1 |

| Precipitate phase | FCC_L12#2 |

| Precipitate Phase Data Parameters (Precipitation Calculator) | |

| Nucleation sites | Bulk |

| Interfacial energy | 0.012 J/m2 |

| Calculation Type (Precipitation Calculator) | |

| Calculation type | Isothermal |

| Temperature | 800° C |

| Simulation time | 1 000 000 seconds |

Visualizations

Many of our Graphical Mode examples have video tutorials, which you can access in a variety of ways. When in Thermo‑Calc, from the menu select Help → Video Tutorials, or from the main My Project window, click Video Tutorials. Alternately, you can go to the website or our YouTube channel.

Open the example project file to review the node setup on the Project window and the associated settings on the Configuration window for each node. For some types of projects, you can also adjust settings on the Plot Renderer Configuration window to preview results before performing the simulation. Click Perform Tree to generate plots and tables to see the results on the Visualizations window.

There is a variety of information shown in the Visualizations window that can be viewed during configuration and after performing the calculation.

- Thermal Profile: When setting up a calculator on a Configuration window for Isothermal or Non-isothermal Calculation Types, you can preview the profile and adjust settings as needed. When you click a calculator node in the Project window, the matching name of the node is on the tab(s) displayed in the Visualizations window.

For TTT Diagram and CCT Diagram calculations there is nothing shown for the Precipitation Calculator tab in the Visualizations window as there is no Thermal Profile to be defined.

- Plot or Table results: After completing the set up and performing the calculation, to view the matching name of the node on tab(s) in the Visualizations window, either click a Plot Renderer or Table Renderer node in the Project window or click the tabs individually in the Visualizations window.

For this Isothermal example, its Thermal Profile is also displayed in the Visualizations window showing the constant temperature entered for this calculation type. The tab names match the node names in the Project window.

Figure 1: After performing the calculation, you can view the result on the applicable tab. This plot compares the predicted evolution of the volume fraction of gamma prime with the measurements of [2008Sud].

Figure 2: After performing the calculation, you can view the result on the applicable tab. This plot compares the predicted evolution of the number density of gamma prime with the measurements of [2008Sud].

Reference

[2008Sud] C. K. Sudbrack, T. D. Ziebell, R. D. Noebe, D. N. Seidman, Effects of a tungsten addition on the morphological evolution, spatial correlations and temporal evolution of a model Ni–Al–Cr superalloy. Acta Mater. 56, 448–463 (2008).

![This plot compares the predicted evolution of the number density of gamma prime with the measurements of [2008Sud]. This plot compares the predicted evolution of the number density of gamma prime with the measurements of [2008Sud].](../../resources/images/tc-prisma/examples/p-05-numden.png)

![This plot compares the predicted evolution of the mean particle radius of gamma prime with the measurements of [2008Sud]. This plot compares the predicted evolution of the mean particle radius of gamma prime with the measurements of [2008Sud].](../../resources/images/tc-prisma/examples/p-05-meanrad.png)