P_08: Precipitation of Cu-Ti CU4TI with Assumptions of Sphere and Needle Morphologies

In this isothermal calculation example, the precipitation of Cu4Ti phase in a Cu-Ti binary alloy is calculated. To make a comparison, two separate simulations are performed, one assuming spherical morphology without elastic strain energy, and the other assuming needle morphology whose shape, determined by competition between interfacial energy and elastic strain energy, is changed during the simulation. The transformation strain is obtained from Borchers [1999Bor]. The results are compared with experiment results from Kampmann et al. [1987Kam].

For more details about the background theory, see Precipitation Morphology.

- Folder: Precipitation Module - TC-PRISMA

- File name:

P_08_Precipitation_Cu-Ti_CU4TI1_Sphere_Needle.tcu

Example Settings

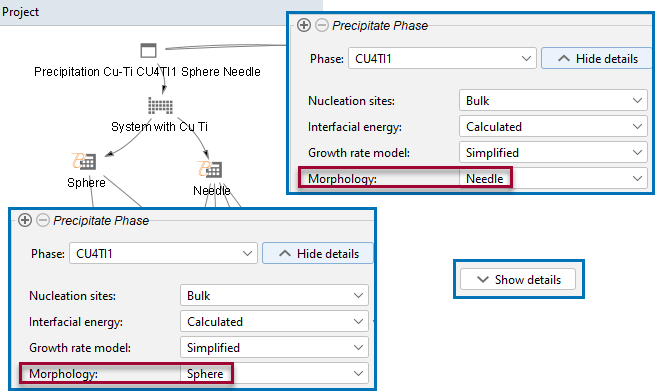

To ensure that the settings are done on the correct Precipitation Calculators, the Sphere and Needle nodes are renamed from Precipitation Calculator to match their morphology. The morphology is set in the Precipitate Phase section when you click Show Details.

| System (System Definer) | |

| Database package |

Demo: Copper-based alloys (CUDEMO and MCUDEMO) |

| Elements |

Cu, Ti |

| Sphere and Needle Conditions (Precipitation Calculator) | |

|

Composition |

Cu-1.9Ti Mole percent |

|

Matrix phase |

FCC_L12 |

|

Precipitate phase |

CU4TI1 |

| Matrix Phase Data Parameters (Precipitation Calculator) | |

| Mobility adjustment > Prefactor (click Show Details to display this setting) | Keep the default, Same for all elements, then enter 100 for the Prefactor. |

| Precipitate Phase Data Parameters (Precipitation Calculator) | |

|

Nucleation sites |

Bulk |

| Interfacial energy |

The default |

| Morphology (click Show Details to display this setting) |

For the Sphere node (renamed from Precipitation Calculator), keep the default. For the Needle node (renamed from Precipitation Calculator), Needle is selected. |

|

Transformation strain (click Show Details to display this setting) |

For the Sphere node (renamed from Precipitation Calculator), keep the default. For the Needlenode (renamed from Precipitation Calculator), User defined is selected. In this example, the following settings are defined:

|

| Calculation Type (Precipitation Calculator) | |

| Calculation type |

Isothermal |

| Temperature |

350° C |

|

Simulation time |

10,000 seconds |

| Datasets (Experimental File Reader) | |

| Borchers Mean radius vs Time and Borchers Number density vs Time | Data sets included with this example and imported to two Experimental File Readers. These data sets are used for the Mean Radius and Number Density plots, respectively. |

Visualizations

Many of our Graphical Mode examples have video tutorials, which you can access in a variety of ways. When in Thermo‑Calc, from the menu select Help → Video Tutorials, or from the main My Project window, click Video Tutorials. Alternately, you can go to the website or our YouTube channel.

Open the example project file to review the node setup on the Project window and the associated settings on the Configuration window for each node. For some types of projects, you can also adjust settings on the Plot Renderer Configuration window to preview results before performing the simulation. Click Perform Tree to generate plots and tables to see the results on the Visualizations window.

When you run (Perform) this example, it takes a few minutes for the calculations to complete.

There is a variety of information shown in the Visualizations window that can be viewed during configuration and after performing the calculation.

- Thermal Profile: When setting up a calculator on a Configuration window for Isothermal or Non-isothermal Calculation Types, you can preview the profile and adjust settings as needed. When you click a calculator node in the Project window, the matching name of the node is on the tab(s) displayed in the Visualizations window.

For TTT Diagram and CCT Diagram calculations there is nothing shown for the Precipitation Calculator tab in the Visualizations window as there is no Thermal Profile to be defined.

- Plot or Table results: After completing the set up and performing the calculation, to view the matching name of the node on tab(s) in the Visualizations window, either click a Plot Renderer or Table Renderer node in the Project window or click the tabs individually in the Visualizations window.

In this example, all nodes are renamed in the Project window, and this matches each of the tab names in the Visualizations window.

For this Isothermal example, its Thermal Profile is also displayed in the Visualizations window showing the constant temperature entered for this calculation type. The tab names match the node names in the Project window.

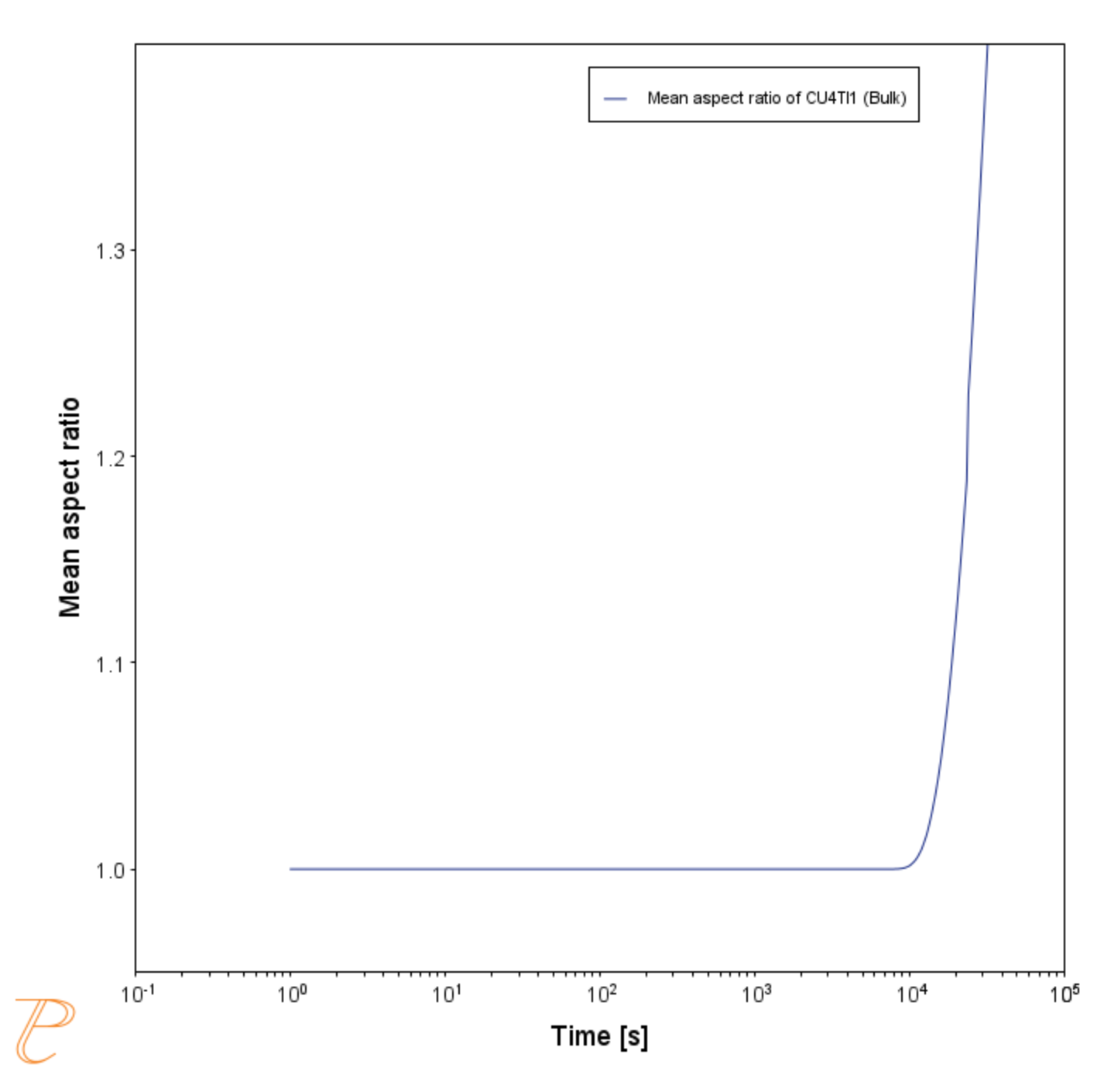

Figure 1: The predicted evolution of the morphology of needle shaped precipitates, showing how the mean aspect ratio changes during the isothermal heat treatment.

Figure 2: The results compare the predicted evolution of the mean size of precipitates with the experimental data from [1987Kam], comparing the spherical and needle shaped approximations of the precipitate morphology. Note how the needle shape approximation is closer to the experimental data.

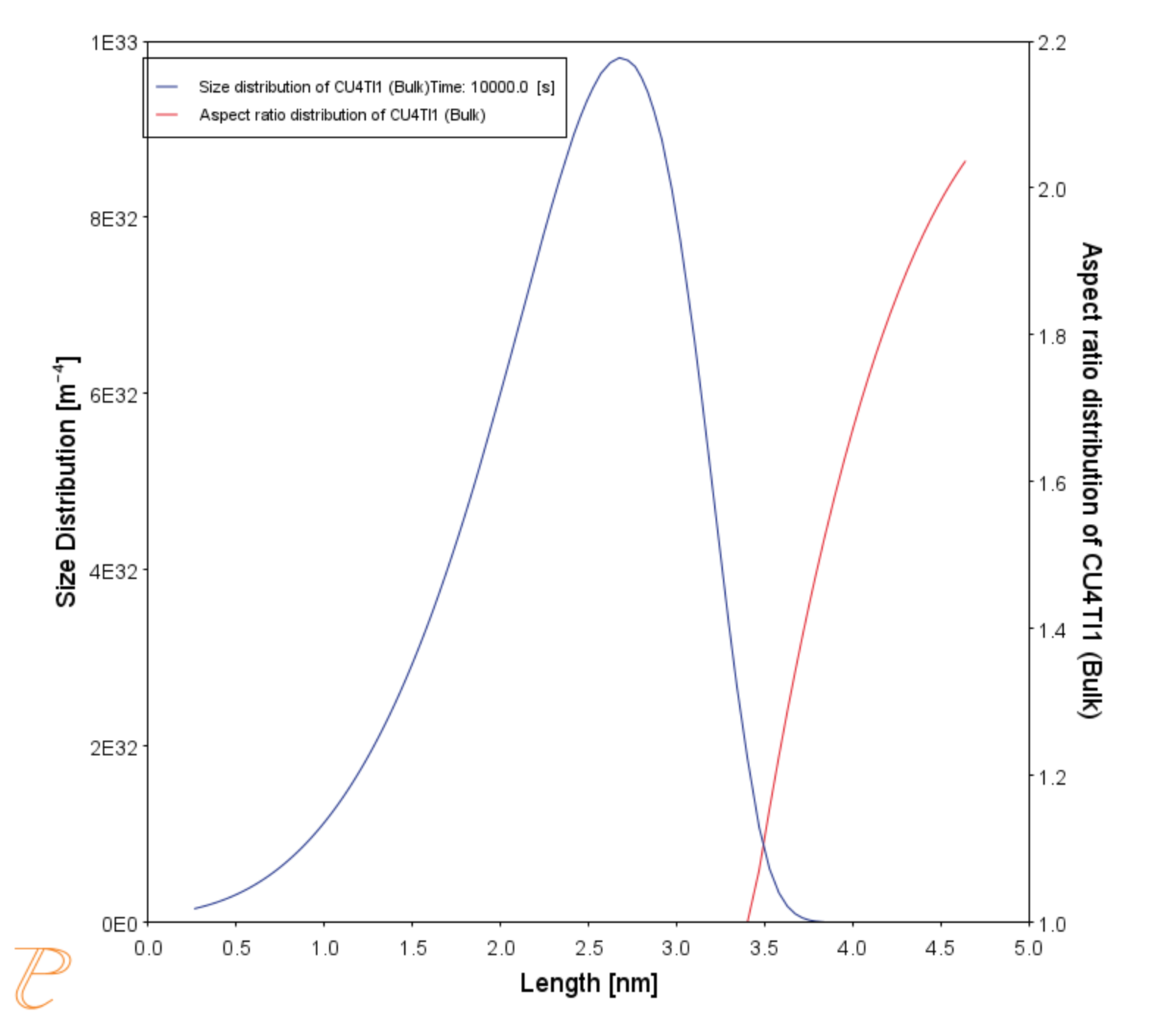

Figure 3: These results show both the predicted final particle size distribution from the needle shape simulation and the predicted relationship between the length of the precipitate and the needle aspect ratio.

Figure 4: This shows the approximates the size of the needle shaped precipitates as a sphere of equivalent volume, and compares the experimental results of [1987Kam] with those obtained from a spherical and needle shaped approximation.

References

[1987Kam] R. Kampmann, H. Eckerlebe, R. Wagner, 1987. "Precipitation Kinetics in Metastab le Solid Solutions - Theoretical Considerations and Application to Cu-Ti Alloys." Mat. Res. Soc. Symp. Proc. 57: 525-542.

[1999Bor] C. Borchers, Catastrophic nucleation during decomposition of Cu-0.9at.% Ti. Philos. Mag. A. 79, 537–547 (1999).

![The results compare the predicted evolution of the mean size of precipitates with the experimental data from [1987Kam], comparing the spherical and needle shaped approximations of the precipitate morphology. Note how the needle shape approximation is closer to the experimental data. The results compare the predicted evolution of the mean size of precipitates with the experimental data from [1987Kam], comparing the spherical and needle shaped approximations of the precipitate morphology. Note how the needle shape approximation is closer to the experimental data.](../../resources/images/tc-prisma/examples/p-08-number density.png)

![This shows the approximates the size of the needle shaped precipitates as a sphere of equivalent volume, and compares the experimental results of [1987Kam] with those obtained from a spherical and needle shaped approximation. This shows the approximates the size of the needle shaped precipitates as a sphere of equivalent volume, and compares the experimental results of [1987Kam] with those obtained from a spherical and needle shaped approximation.](../../resources/images/tc-prisma/examples/p-08-mean radius.png)