P_01: Isothermal Precipitation of Al3Sc

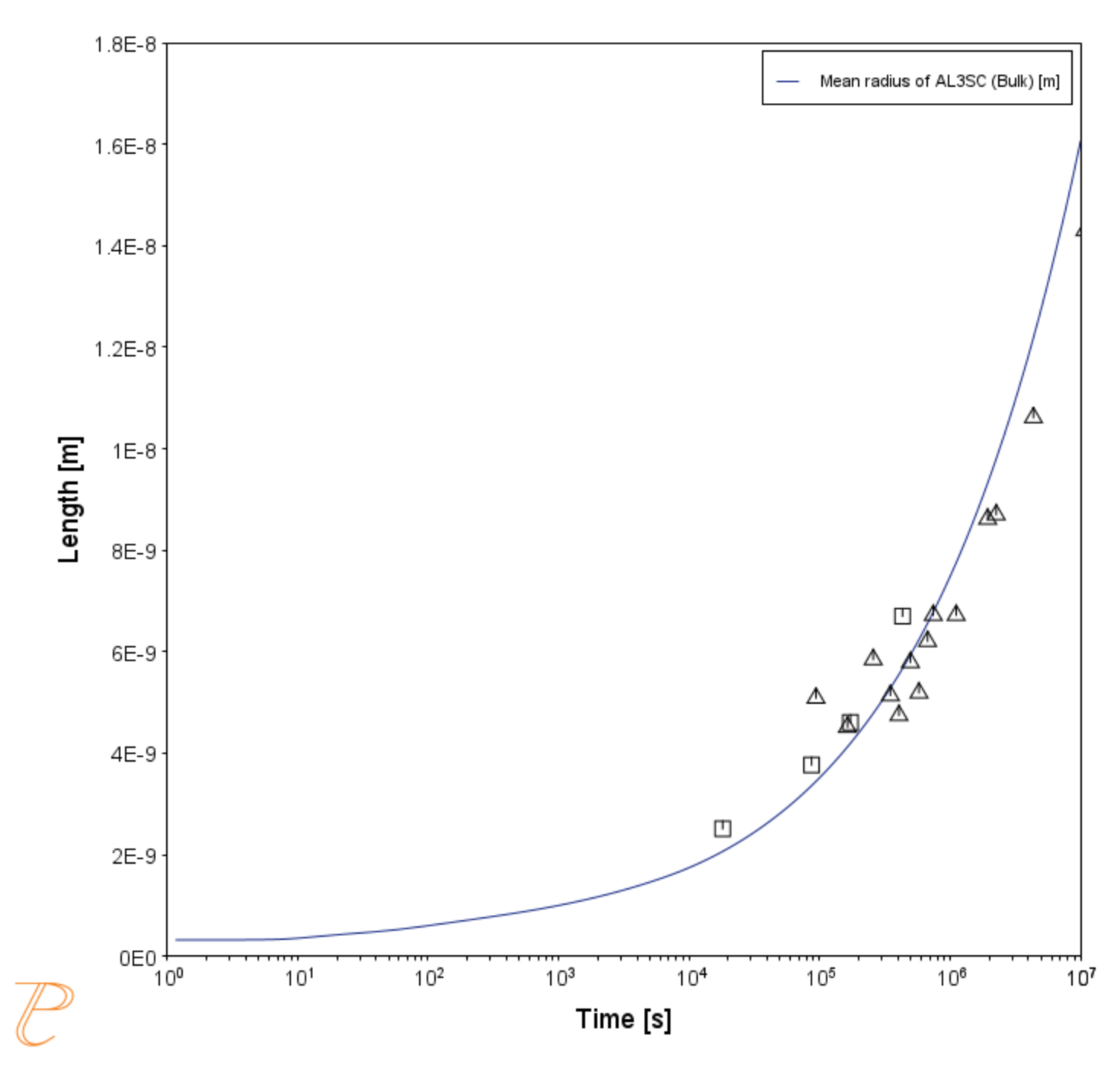

This example simulates the kinetics of precipitation of Al3Sc from an FCC_A1 solution phase. The simulation results can be compared with experimental data collected from Marquis and Seidman [2001Mar] and Novotny and Ardell [2001Nov].

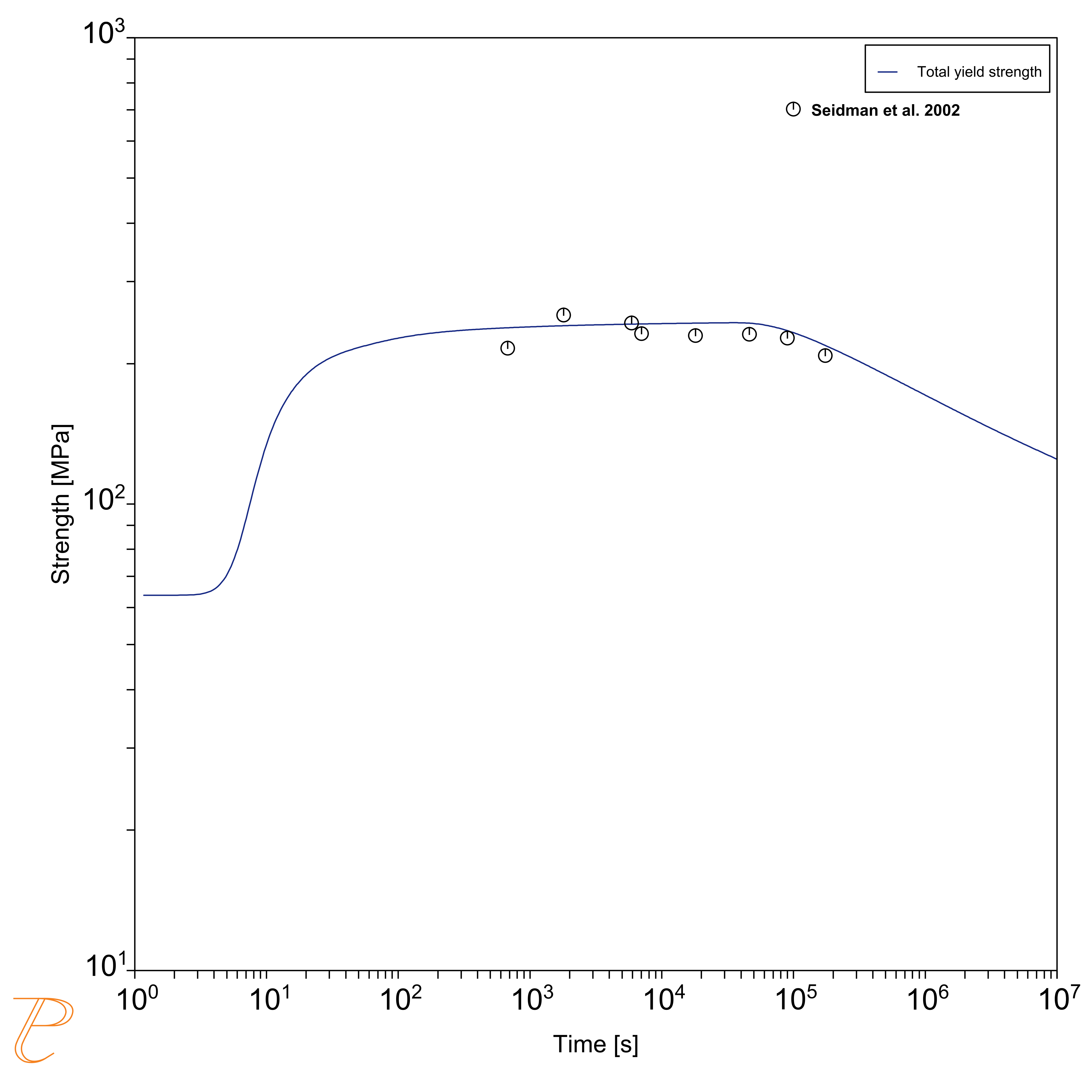

This example also includes a plot using the Yield strength Property Model. This demonstrates how you can use the results from a Precipitation Module (TC-PRISMA) simulation as input to the Yield Strength Model, i.e. the calculated precipitate radius/radii for each time step is used to calculate the precipitation strengthening, and similarly, the matrix composition for each time step is used to calculate the solid solution strengthening when this is selected in the Configuration on the Plot Renderer. The experimental data for the Yield Strength Model is from Seidman et al. [2002Sei]. In this example, the Precipitation strengthening model used is Seidman model (Al-base). This is selected on the Plot Renderer configuration panel that is connected to the Property Model.

About the Yield Strength Property Model

- Folder: Precipitation Module - TC-PRISMA

- File name:

P_01_Precipitation_Al-Sc_AL3SC.tcus

Example Settings

| System (System Definer) | |

| Database package | Demo: Aluminum-based alloys (ALDEMO, MALDEMO) |

| Elements | Al, Sc |

| Conditions (Precipitation Calculator) | |

|

Composition |

Al-0.18Sc Mole percent |

|

Matrix phase |

FCC_A1 |

|

Precipitate phase |

AL3SC |

| Precipitate Phase Data Parameters (Precipitation Calculator) | |

| Nucleation sites | Bulk |

| Interfacial energy | Calculated |

| Calculation Type (Precipitation Calculator) | |

|---|---|

| Calculation type | Isothermal |

|

Temperature |

350° C |

|

Simulation time |

1.0E7 seconds |

| Experimental File Reader 1 and 2 | |

| There are two Experimental File Reader nodes used. One for the mean radius plot and one to demonstrate the Yield Strength Property Model. | |

Visualizations

This example is included as a Precipitation Module (TC-PRISMA) tutorial on our website and as part of the playlist on our YouTube channel.

Open the example project file to review the node setup on the Project window and the associated settings on the Configuration window for each node. For some types of projects, you can also adjust settings on the Plot Renderer Configuration window to preview results before performing the simulation. Click Perform Tree to generate plots and tables to see the results on the Visualizations window.

There is a variety of information shown in the Visualizations window that can be viewed during configuration and after performing the calculation.

- Thermal Profile: When setting up a calculator on a Configuration window for Isothermal or Non-isothermal Calculation Types, you can preview the profile and adjust settings as needed. When you click a calculator node in the Project window, the matching name of the node is on the tab(s) displayed in the Visualizations window.

For TTT Diagram and CCT Diagram calculations there is nothing shown for the Precipitation Calculator tab in the Visualizations window as there is no Thermal Profile to be defined.

- Plot or Table results: After completing the set up and performing the calculation, to view the matching name of the node on tab(s) in the Visualizations window, either click a Plot Renderer or Table Renderer node in the Project window or click the tabs individually in the Visualizations window.

Figure 1: During set up of the calculation, preview the Thermal Profile. Click the tab in the Visualizations window to preview it. For an Isothermal Thermal Profile this shows the constant temperature as entered.

Figure 2: After performing the calculation, you can view the result on the applicable tab. This plot shows the mean radius of the AL3SC precipitate as a function of time.

Figure 3: After performing the calculation, you can view the result on the applicable tab. This plot shows the total yield strength of the AL3SC precipitate as a function of time compared to experimental data from Siedmen et al. [2002Sei]. The model captures the over-tempering behavior from excessive coarsening of the strengthening precipitates.

References

[2001Mar] E. A. Marquis, D. N. Seidman, Nanoscale structural evolution of Al3Sc precipitates in Al(Sc) alloys. Acta Mater. 49, 1909–1919 (2001).

[2001Nov] G. M. Novotny, A. J. Ardell, Precipitation of Al3Sc in binary Al–Sc alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 318, 144–154 (2001).

[2002Sei] D. N. Seidman, E. A. Marquis, D. C. Dunand, Precipitation strengthening at ambient and elevated temperatures of heat-treatable Al(Sc) alloys. Acta Mater. 50, 4021–4035 (2002).