T_18: Scheil with Delta Ferrite to Austenite Transition

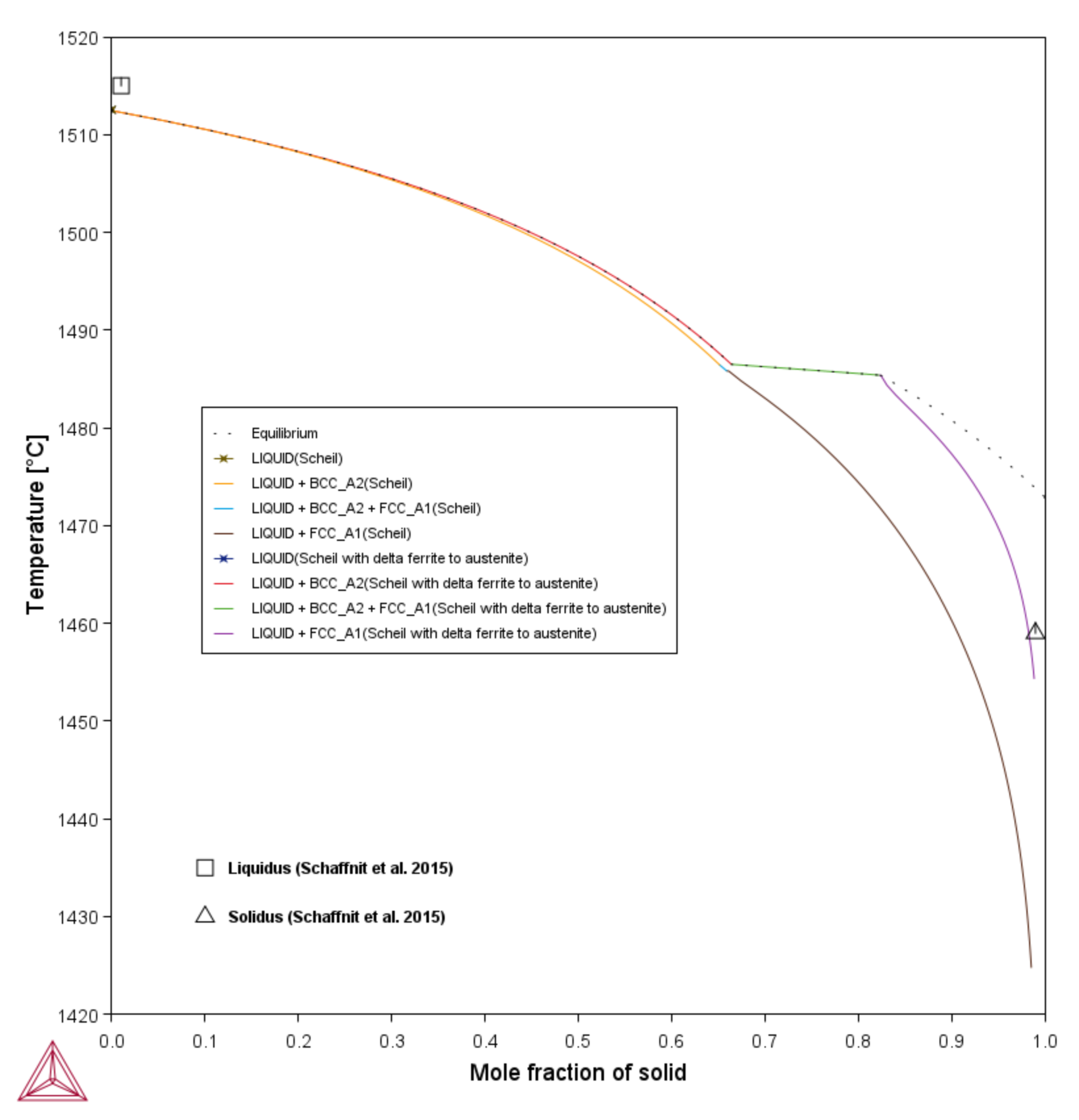

This is a example of a Scheil solidification simulation using an Fe-0.23C-0.19Si-0.47Mn-0.92Cr-0.09Ni-0.3Mo (wt%) alloy (Steel P) [2015Sch], which is a steel that undergoes the peritectic transformation.

The result of a Scheil Calculator with the default Classic Scheil calculation type is compared to a the result of a calculator where the setting Allow delta ferrite to austenite transition in steel is selected. Carbon ( C ) is set as a Fast diffuser in both. A comparison to experimental solidus temperature from Schaffnit et al. [2015Sch] shows that for this steel, using the Allow delta ferrite to austenite transition in steel option gives a much better agreement with experiment than the standard Classic Scheil.

See Scheil Calculator for an overview of the different Scheil simulation models available.

- Folder: Thermo‑Calc

- File name: T_18_Scheil_with_Delta_Ferrite_to_Austenite_Transition.tcu

This uses the TCFE database. A license is required to run the example.

Visualizations

Many of our Graphical Mode examples have video tutorials, which you can access in a variety of ways. When in Thermo‑Calc, from the menu select Help → Video Tutorials, or from the main My Project window, click Video Tutorials. Alternately, you can go to the website or our YouTube channel.

Open the example project file to review the node setup on the Project window and the associated settings on the Configuration window for each node. For some types of projects, you can also adjust settings on the Plot Renderer Configuration window to preview results before performing the simulation. Click Perform Tree to generate plots and tables to see the results on the Visualizations window.

Figure 1: Mole fraction of solid as a function of temperature comparing the liquidus and solidus from experimental data [2015Sch].

Reference

[2015Sch] P. Schaffnit, C. Stallybrass, J. Konrad, F. Stein, M. Weinberg, A Scheil–Gulliver model dedicated to the solidification of steel. Calphad. 48, 184–188 (2015).