Normal Grain Growth

The normal grain growth model in the Precipitation Module (TC-PRISMA) uses a similar approach to its precipitation counterpart (see Theory Overview) in that it calculates the temporal evolution of grain size distribution (GSD). The grains are assumed of spherical morphology when modeling the growth rates. Nucleation is not considered, thus an initial GSD is necessary to start the simulation.

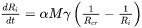

The boundary motion of a grain with radius  without considering pinning forces from precipitate particles, is driven by curvature and can be modeled as [1957Fel; 1965Hil]

without considering pinning forces from precipitate particles, is driven by curvature and can be modeled as [1957Fel; 1965Hil]

where

-

is grain boundary mobility (

is grain boundary mobility ( )

) -

is the grain boundary energy (

is the grain boundary energy ( )

) -

is a dimensionless constant

is a dimensionless constant

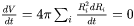

If it should be satisfied that  , which is the parabolic growth rate of average grain size at steady-state

, which is the parabolic growth rate of average grain size at steady-state

[Eq. 2]

It was found that  [1965Hil].

[1965Hil].

in Eq. 1 is the critical grain size, which, not necessarily the average grain size, is determined by volume conservation [2008Jep]

in Eq. 1 is the critical grain size, which, not necessarily the average grain size, is determined by volume conservation [2008Jep]

where the index  covers all the grains at each time step. Substituting Eq. 1 into Eq. 3,

covers all the grains at each time step. Substituting Eq. 1 into Eq. 3,  is obtained at each time step.

is obtained at each time step.

Grain Boundary Mobility Values

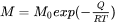

The grain boundary mobility  can be calculated as:

can be calculated as:

[Eq. 4]

where

-

is the prefactor (m4/Js)

is the prefactor (m4/Js) -

is the activation energy (J/mol)

is the activation energy (J/mol)

The recommended values of  and

and  in high purity metals such as ferritic iron, austenitic iron, nickel, and aluminum are shown in the table below.

in high purity metals such as ferritic iron, austenitic iron, nickel, and aluminum are shown in the table below.

Since grain growth is significantly affected by grain boundary segregation, precipitation, and grain boundary complexion, the accuracy of the mobility data used for the recommended values is not guaranteed.

If the grain size is in nanoscale, these parameters may not be applicable since the effects of grain boundary junction and complexion cannot be ignored in nanocrystals. For some alloys, such as Al, the parameters can also be sensitive to temperature. The temperature range in the table is the suggested best fit.

Recommended grain growth parameters for mobility prefactor  and activation energy

and activation energy  .

.

| Matrix Phase | Temperature Range (K) | Prefactor M0 (m4/Js) | Activation Energy Q (J/mol) | Reference | |

|---|---|---|---|---|---|

| High purity iron | BCC_A2 | 625 ~ 875 | 4E-3 | 242000 | [1997Mal] |

| Low alloying steel (Cr-Mo) | FCC_A1 | 1173 ~ 1473 | 3.6E-3 | 228302 | [2008Lee] |

| Pure Ni | DIS_FCC_A1/FCC_L12 | 1098 ~ 1323 | 4.12E-8 | 123050 | [2008Ran] |

| High purity aluminum | FCC_A1 |

300 ~ 548 |

1.02E-14 |

27430 |

[2004Yu] |

|

573 ~ 773 |

1.25E-8 |

73080 |

References

[1957Fel] P. Feltham, Grain growth in metals. Acta Metall. 5, 97–105 (1957).

[1965Hil] M. Hillert, On the theory of normal and abnormal grain growth. Acta Metall. 13, 227–238 (1965).

[1997Mal] T. R. Malow, C. C. Koch, Grain growth in nanocrystalline iron prepared by mechanical attrition. Acta Mater. 45, 2177–2186 (1997).

[2004Yu] C. Y. Yu, P. L. Sun, P. W. Kao, C. P. Chang, Evolution of microstructure during annealing of a severely deformed aluminum. Mater. Sci. Eng. A. 366, 310–317 (2004).

[2008Jep] J. Jeppsson, J. Ågren, M. Hillert, Modified mean field models of normal grain growth. Acta Mater. 56, 5188–5201 (2008).

[2008Lee] S.-J. Lee, Y.-K. Lee, Prediction of austenite grain growth during austenitization of low alloy steels. Mater. Des. 29, 1840–1844 (2008).

[2008Ran] V. Randle, P. R. Rios, Y. Hu, Grain growth and twinning in nickel. Scr. Mater. 58, 130–133 (2008).