PM_G_05: Yield Strength NiAlCr

The example uses the Property Model Calculator and the Yield strength Property Model with a thermodynamic demonstration nickel database (NIDEMO).

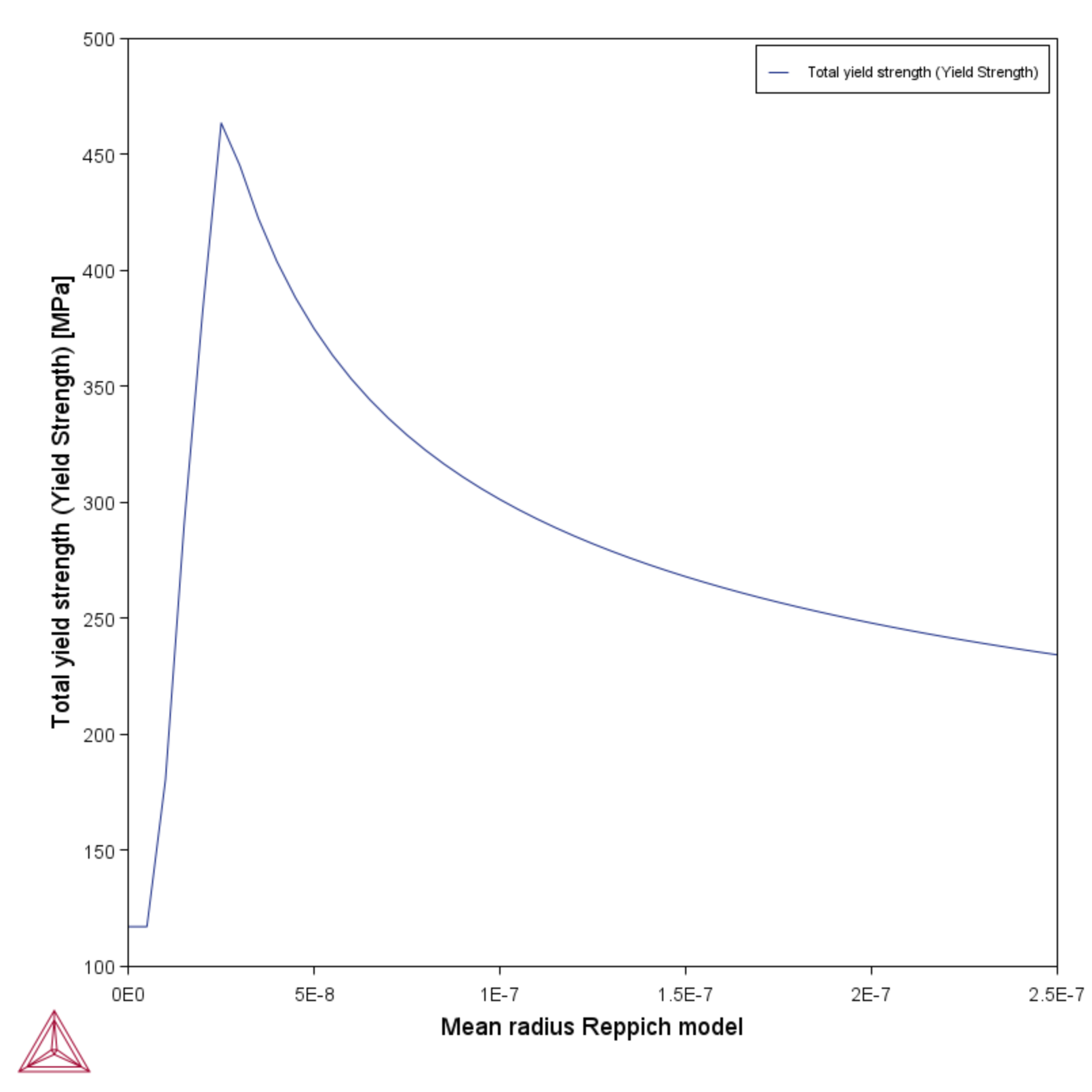

The Reppich model is developed for calculation of precipitation strengthening in Ni-based super alloys consisting mainly of gamma prime (γ') precipitates in a gamma matrix. The example shows a calculation of the precipitation strengthening vs precipitate radius in a Ni-10at%Al-10at%Cr alloy.

This example uses the Reppich model [1982Rep] which is developed and rests on existing hardening models estimating the increase of the yield stress due to pairwise particle cutting and antiphase domain boundary (APB) formation. The effect of the anisotropy on the dislocation line tension of two-phase material and on the Orowan stress is taken into account. Compared to conventional APB hardening theories, this model can be applied to large volume fraction of precipitates in the anisotropic systems.

For more settings information, see Yield Strength Property Model: Simplified Mode Settings and for additional theoretical information about the models, see About the Yield Strength Property Model.

For the settings input of the Reppich model (Ni-base):

- A is a numerical factor depending on the morphology of the precipitates. For spherical particles, A equals to 0.72.

- w represents the elastic repulsion between the strongly paired dislocations, which can be determined by the experimental data [1979Hüt].

In this example, A and w are set by default to 0.7639 and 0.2919, respectively. The C factor default of 0 is not changed.

- Folder: Property Models → General

- File name: PM_G_05_Yield_Strength_NiAlCr.tcu

Visualizations

Many of our Graphical Mode examples have video tutorials, which you can access in a variety of ways. When in Thermo‑Calc, from the menu select Help → Video Tutorials, or from the main My Project window, click Video Tutorials. Alternately, you can go to the website or our YouTube channel.

Open the example project file to review the node setup on the Project window and the associated settings on the Configuration window for each node. For some types of projects, you can also adjust settings on the Plot Renderer Configuration window to preview results before performing the simulation. Click Perform Tree to generate plots and tables to see the results on the Visualizations window.

Figure 1: Reppich model plotted with results and experimental data for PE16, all data is normalized with the square root of the volume fraction of precipitate.

References

[1979Hüt] W. Hüther, B. Reppich, Order hardening of MgO by large precipitated volume fractions of spinel particles. Mater. Sci. Eng. 39, 247–259 (1979).

[1982Rep] B. Reppich, Some new aspects concerning particle hardening mechanisms in γ’ precipitating Ni-base alloys—I. Theoretical concept. Acta Metall. 30, 87–94 (1982).