AM_06b: Using the Calibrated Heat Source for a 316L Steel

This example demonstrates the use of the two calibrated heat sources that are saved in the example AM_06a. One heat source is of the Gaussian type while the other heat source is Double ellipsoidal. For both heat sources, expressions are saved as a function of energy density (P/v) for all heat source parameters as well as the absorptivity. The example consists of four AM Calculators, two of which use a Gaussian heat source while the other two use a Double ellipsoidal heat source, and where the processing conditions for all four AM Calculators are taken from Hu et al [2019Hu].

AM_06a: Calibrating a Heat Source for a 316L Steel

- Folder: Additive Manufacturing

- File name:

AM_06b_Use_Calibrated_Heat_Sources_316L.tcu

Other than an Additive Manufacturing (AM) Module license, this example does not require an additional license to run it, although its companion example, AM_06a, does.

Material Properties

- SS316L: Fe-17.0Cr-12.0Ni-2.5Mo-0.03C Mass percent

- Database: TCFE13

- The material properties are precalculated, and stored as a built-in material library with the Additive Manufacturing (AM) Module.

Configuration and Calculation Set Up

There are four AM Calculators where all the calculators use the Steady-state simulation type and the Single point Calculation Type. The purpose of this example is to use the saved heat sources from AM_06a and then validate the results by comparing the melt pool size from the simulations with the experimental melt pool dimensions as given in Hu et. al [2019Hu].

The saved heat sources are selected from the Heat Source list on the AM Calculator, where a subsection called Users heat sources includes all previously saved heat sources. In the example, two calculators use the Gaussian - 316L - beam d 15um user-defined heat source, and two use the Double ellipsoidal - 316L - beam d 15um user-defined heat source. The Base plate temperature and Ambient temperature is set to 353 K, while the Layer thickness is set to 10 μm.

Visualizations

Open the example project file to review the node setup on the Project window and the associated settings on the Configuration window for each node. For some types of projects, you can also adjust settings on the Plot Renderer Configuration window to preview results before performing the simulation. Click Perform Tree to generate plots and tables to see the results on the Visualizations window.

When you run (Perform) this example, it takes a few minutes for the calculations to complete.

There is a variety of information shown in the Visualizations window that can be viewed during configuration and after performing the calculation(s).

For this example, it is best to open and run this simulation to be able to view all the different plots and outputs to various tabs on both the various Configuration windows as well as the Visualizations window.

See Visualizing Heat Source Calibrations for an extended overview of what is available and how to navigate the many options for visualizing the heat source calibration data.

Gaussian Heat Source and Keyhole Model

The different processing conditions are selected to simulate both the conduction mode as well as the keyhole mode. For Gaussian - 316L - beam d 15 um heat source, with P = 100 W and scanning speed = 2800 mm/s, the dominant mode of heat transfer is conduction, which is why a shallow melt pool is obtained. The results from the simulations are fairly close to the ones from the experiments, as can be seen in Table 1.

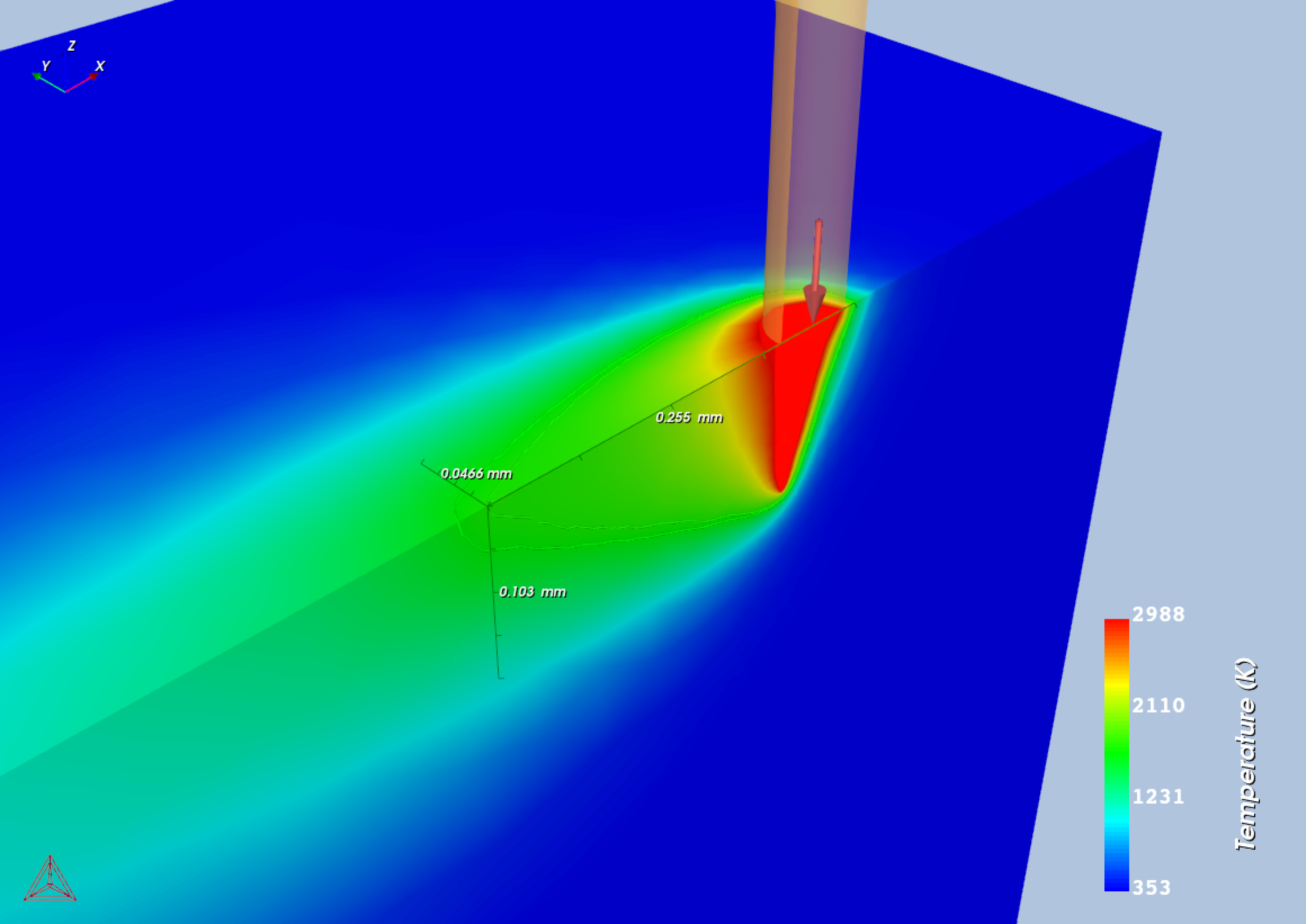

With P = 80 W and scanning speed = 400 mm/s, a keyhole mode is observed in the experiments. This is also predicted from the simulations as can be seen in Figure 1.

A comparison of the melt pool depth from the simulations and the experiments for the latter case shows that the calibrated Gaussian heat source with the keyhole model predicts the melt pool depth with reasonable accuracy. However, it underpredicts the melt pool width. This is because fluid flow due to Marangoni forces is not included in these simulations, which probably causes the melt pool to widen in the experiments.

| Calculator Name | Power [W] | Scanning Speed [mm/s] | Melt Pool Width | Melt Pool Depth | ||

|---|---|---|---|---|---|---|

| Simulation [μm] | Experiment [μm] | Simulation [μm] | Experiment [μm] | |||

|

AM use calibrated Gaussian P100 u2800 |

100 | 2800 | 53.30 | 47.82 | 12.93 | 14.36 |

|

AM use calibrated Gaussian P80 u400 |

80 | 400 | 93.25 | 105 | 102.71 | 106.57 |

Table 1: A comparison of the melt pool dimensions from the simulations and experiments using the calibrated Gaussian heat source.

Figure 1: Steady-state temperature distribution around the melt pool for SS316L with P = 80 W and scanning speed = 400 mm/s using the calibrated Gaussian heat source with the keyhole model. A keyhole can also be seen formed just below the location of the heat source.

Double Ellipsoidal Heat Source

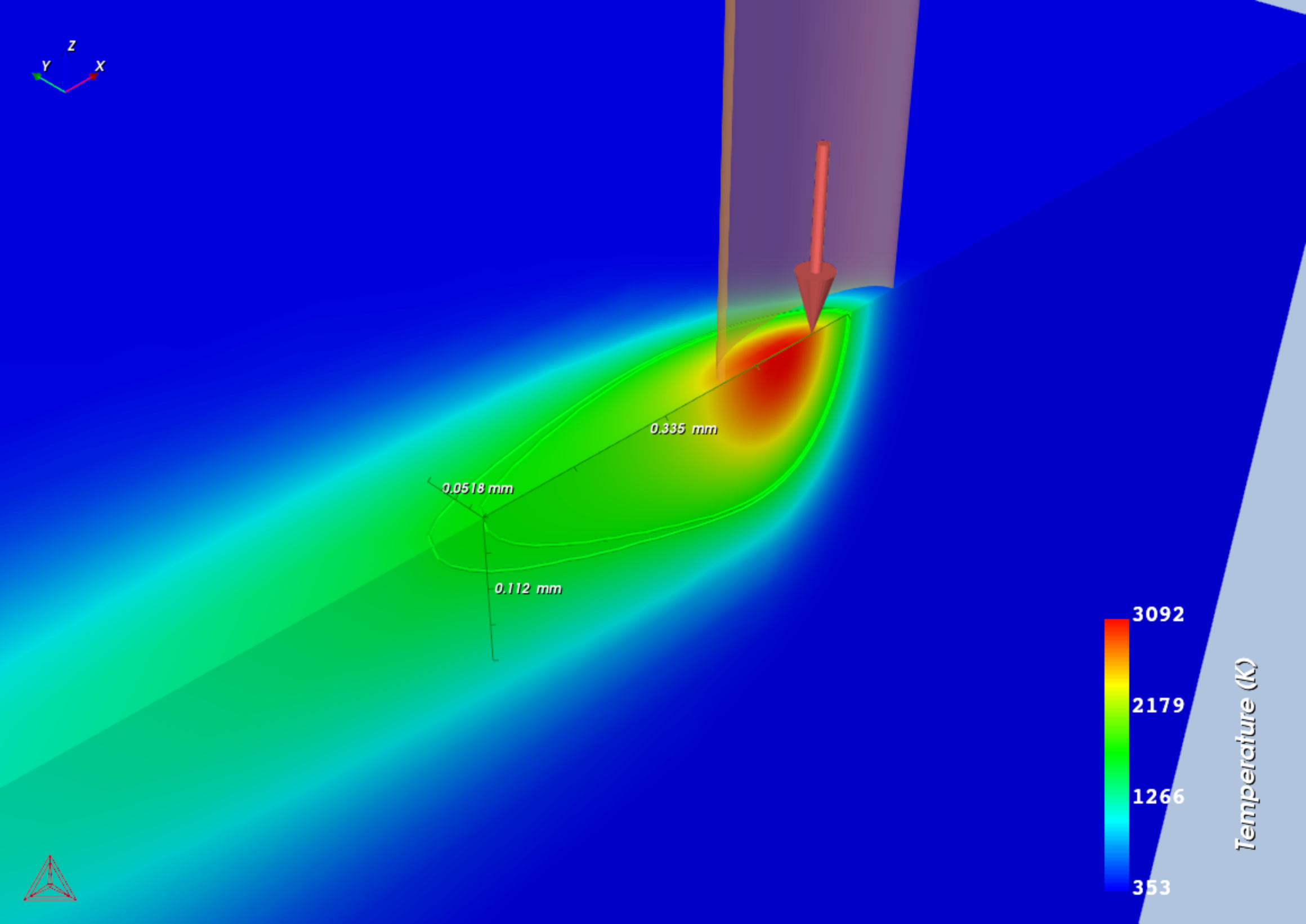

For the Double ellipsoidal - 316L - beam d 15 um heat source, two different processing conditions are selected to simulate both the conduction mode as well as the keyhole mode. For both processing conditions, the prediction of the melt pool size from the simulations is in fairly good agreement with the results from the experiments as can be seen in Table 2.

The temperature distribution using the calibrated double ellipsoidal heat source with P = 80 W and scanning speed = 400 mm/s is shown in Figure 2.

| Calculator Name | Power [W] | Scanning Speed [mm/s] | Melt Pool Width | Melt Pool Depth | ||

|---|---|---|---|---|---|---|

| Simulation [μm] | Experiment [μm] | Simulation [μm] | Experiment [μm] | |||

|

AM use calibrated DE P80 u1200 |

100 | 1200 | 65.07 | 64.34 | 31.63 | 29.68 |

|

AM use calibrated DE P80 u400 |

80 | 400 | 103.65 | 105 | 112.29 | 106.57 |

Table 2: A comparison of the melt pool dimensions from the simulations and experiments using the calibrated double ellipsoidal heat source.

Figure 2: Steady-state temperature distribution around the melt pool for SS316L with P = 80 W and scanning speed = 400 mm/s using the calibrated double ellipsoidal heat source.

Reference

[2019Hu] Z. Hu, B. Nagarajan, X. Song, R. Huang, W. Zhai, J. Wei, Formation of SS316L Single Tracks in Micro Selective Laser Melting: Surface, Geometry, and Defects. Adv. Mater. Sci. Eng. 2019, Article ID 9451406, 1–9 (2019).

Other Resources

Read more about the Additive Manufacturing (AM) Module on our website including the details about database compatibility or to watch an introductory webinar. You can also use the Getting Started Guide to learn about the key features available.

Many of our Graphical Mode examples have video tutorials, which you can access in a variety of ways. When in Thermo‑Calc, from the menu select Help → Video Tutorials, or from the main My Project window, click Video Tutorials. Alternately, you can go to the website or our YouTube channel.